What is the fastest and most economical way to get started woodturning? You might be surprised by how easy it is for you to turn your first bowl or spindle!

You really only need three things to get into woodturning: a lathe of some sort, some tools to shape the wood and a way to sharpen those tools. And now, it may be down to just two things. It’s so easy that, with the recommendations that follow, you can be turning in 10 minutes flat!

The Bare Basics

You still need a lathe and some tools, but what if — at least as you get started in the craft — you could avoid sharpening your tools? With the new carbide insert tools from Rockler, that’s the case. The replaceable carbide cutting tips mean that you won’t need to sharpen them, ever. They are a very practical way to get your feet wet in woodturning, although if you really get turned on by the craft, you will certainly add some more traditional tools to your arsenal. I know when I started woodturning, one of my concerns was getting a good sharp edge on gouges, because they had those curved cutting surfaces. As an instrument maker, I used many gouges and carving tools, and bringing them to a razor edge was a task that I did not enjoy. These carbide insert tools let beginners avoid that process when starting out. How cool is that?

VIDEO: Turning Tools that never need sharpening.

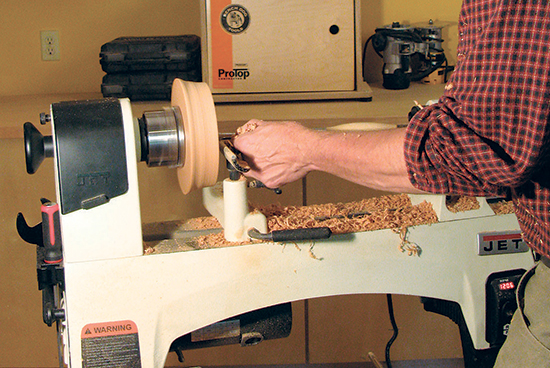

Now, if you need a lathe, what sort should you get? As with most tools, the answer is: the best you are comfortable paying for. My dad used to say, “Buy the best you can afford, and you only cry once.” With that said, what we are talking about here is a reasonable way to explore woodturning to see if it is in your wheelhouse or not. Smaller lathes like the JET shown at left are a good entry point. Used equipment is often a good option if you have the skills to judge whether a piece of equipment is in good working order or not. (My first lathe was a 10-year-old Delta. I used it for seven more years, and when I upgraded it was still working — so I gave it to a friend!) The lathe should have enough power that it won’t bog down (a 1/2hp motor is a minimum), and it needs a way to change speeds, whether that’s by changing drive belt positions or other means: you need some control over the RPM of the stock you will be turn- ing. The regular accessories of a faceplate, banjo/tool-rest, drive and live centers should come standard with the lathe, and if they don’t, you might want to find a different choice.

One More Thing

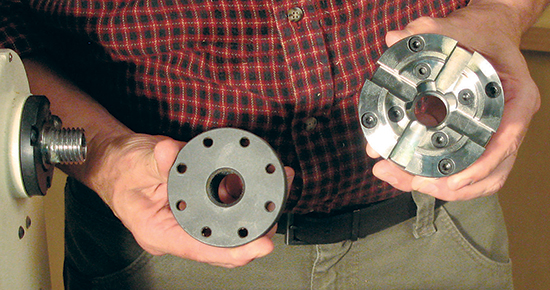

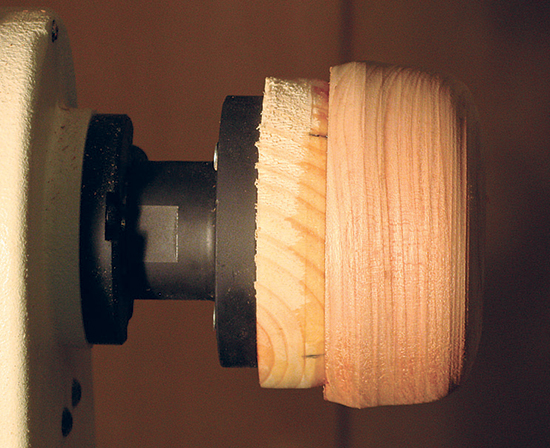

Now I am going to add something that is beyond the basics, but it will be so useful right away that I think you should go for it. Get yourself some sort of scroll chuck to make faceplate turning (like for bowl turning) so much easier and fast- er. You don’t need to, but it was a revelation to me when I got one. Fair warning: you may pay nearly as much for the scroll chuck as you might for one of the most inexpensive lathes — but if your focus is going to be more towards bowl turning rather than spindle turning, I think you will find the purchase to be worth it. That is not to say that you can’t do faceplate turning without one. In that case, you will use the tried- and-true faceplate (likely provided with your lathe) and attach your turning stock in a variety of ways. These include: directly screwed onto the faceplace; glued to a sacrificial piece of wood which is then screwed to the faceplate; and a variety of jam-chucks (more sacrificial stock); and tape-on solutions. These techniques have worked for years and years, so don’t be afraid to embrace them instead of the scroll chuck.

Jump Right In

Woodturning’s popularity is on the rise, and for good reason. It is a creative and safe form of woodworking that does not require a lot of space. If you are interested and have held off due to the fear of tool sharpening and other “non-flat” woodworking considerations, I hope this has been helpful. Turning is different from flat stock woodworking in many ways, but the enjoyment of the craft is much the same. If you are curious, you can be turning in 10 minutes!

Rob Johnstone is a professional woodworker and the publisher of the Woodworker’s Journal. He’s an enthusiastic (if less than expert) woodturner.

LEARN MORE!

Want to learn more about getting started in woodturning? Find the DVD on this topic in our Store.