If you’re as tuned in to home improvement as you are to woodworking, you might remember about three years ago when the floodgates seemed to open up in the marketplace for oscillating multi-tools. Suddenly, FEIN Power Tools wasn’t the only company making those versatile “jacks-of-all-trades” tools that cut, scrape, grind and sand all by switching from one accessory to another.

There’s a simple explanation: FEIN lost its patent on the oscillating mechanism that, quite literally, is the heart and soul of a multi-tool. Other manufacturers saw an opportunity and had their own variations of multi-tools already in production or ready for sale. That’s the way it goes in free enterprise. Now, you can buy multi-tools from at least a half dozen other manufacturers and at some hard-to-resist prices.

But, Ernie Leopold, product manager for FEIN, will argue that FEIN’s orange multi-tools continue to set the standard by which all other multi-tools should be measured. He sums up the reason why in four words: “German innovation. German engineering.” That, plus a legacy of tool developments that span the company’s 145-year history.

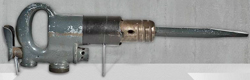

A timeline on FEIN’s website documents some significant achievements that should be of interest to tool fans. FEIN engineered the world’s first handheld power tool, an electric hand drill, in 1895. Eleven years later, FEIN created the first portable electric grinder. The year 1914 ushered in the first pneumatic electric hammer, and in 1933 the company launched a jigsaw for sheet metal processing. FEIN also credits itself in developing an oscillating electric tool that made it safer to remove plaster casts without injuring the skin underneath. FEIN has been making plaster cast saws for medical use since 1945.

“If you consider the physics of how power tools work, there are really only three options of motion: rotary, reciprocating or oscillating. We invented the first tool mechanisms to facilitate all three of these options. We’ve been innovating power tools for a very, very long time.”

One of the next big tool breakthroughs happened in 1985, when FEIN developed an oscillating cutting tool for removing windshields from automobiles. Leopold explained that, prior to this time, auto glass was anything but easy to remove due to the urethane adhesive that holds it in place. Essentially, it was a two-man job: one person inside the car and the other outside cutting through the urethane with an abrasive wire drawn back and forth. The process was labor-intensive and slow, but it was the best method at the time. Other cutting tools were tried, but they tended to damage the surrounding metal or its galvanized coating. FEIN’s solution was to borrow the oscillating mechanism from the cast saw and create a handheld tool with contoured knife blades that could separate auto glass from metal in a fraction of the time. Within the auto industry, it was revolutionary. The tool, which became known as a “FEIN knife,” is still widely used today, and the company makes specific blades to suit most manufacturers’ car models.

Then, in 1986, FEIN brought the first triangular pad sander to market. Called the Delta Sander, this new oscillating tool excelled where other eccentric sanders couldn’t: it could sand into corners without damaging the surrounding areas. “When we first rolled it out, the triangular pad sander sold for $600 to $700, but those who needed a sander for confined areas saw its value right away. There was nothing else like it. It really took off with woodworkers, window restorers and remodelers,” Leopold says.

That tool, with a modified head and a set of various cutting accessories, evolved into the company’s first multi-tool in the mid 1990s. “We created the MultiMaster because people wanted to do more with their triangular-pad sanders than just sand. We developed the tooling and the tool mechanism to help those early DIYers get a variety of jobs done.”

Since that time, FEIN has become an industry leader in multi-tool innovations. In 2007, the QuickIn™ rapid change system made it possible to change from sanding to cutting, scraping or grinding accessories by simply flipping a lever. FEIN has also developed more than 50 different accessories for its MultiMaster and SuperCut multi-tools. In recent years, the company introduced lithium-ion cordless versions that, Leopold assures, are as powerful as their corded counterparts.

Still, the reality of the current multi-tool market is that there are many other color choices than orange these days. The glut of other economically priced multi-tools might have the budget-conscious consumer wondering, why spend $400 or more on a FEIN multi-tool? It’s a concern Ernie hears quite often, mostly from end users that have never tried a FEIN tool.

“I tell folks, all of our multi-tools are made in our German manufacturing plant to our rigid specifications. We don’t cut corners on cost or compromise on quality, and we don’t make tools in Asia. Our tools and accessories are engineered for durability and made with the highest quality materials, and that ensures value over the long term as it always has. Until you experience a FEIN tool in your own hands and see for yourself, this can be hard to understand.”

Just recently FEIN announced a new packaging solution to do just that: to help put a FEIN multi-tool into more DIYers and woodworkers’ hands at a significantly lower price. The company is now offering a corded FM250Q MultiMaster with a nylon carry bag and a basic set of accessories (universal saw blade for metal and wood, rigid scraper blade, sanding attachment and sanding pads) for $199. It’s an opportunity to own the same MultiMaster tool found in the company’s other kits, but for about half the price of its MultiMaster Top Plus system that comes with a rigid plastic case and a broader range of accessories.

“With this new entry-level MultiMaster system, we want to help more people experience why we still make the world’s best oscillating tool. We wrote the book on this technology, and we plan to continue writing more chapters in the years to come with products that innovate rather than follow behind.”