When students start back to school in the fall, the teachers usually take at least a bit of time to review what was previously learned. It can be a worthwhile endeavor, especially if you can clear up any questions. That’s what we’ve tried to do this time out, with some questions focused on the topics of previously published finishing columns.

I enjoyed your tip suggesting coating a cutting board with paraffin. In sharing it with my wife, she wondered what would happen if you put a hot roast on the board for cutting. Will the hot meat melt the paraffin coating?

– Terry Elfers

Cincinnati, Ohio

Canning paraffin, which is what we used in the article, starts to melt at about 100° F., so yes, a very hot roast could theoretically soften or even melt wax. It would not matter much because you scrape all the paraffin off except what resides in the pores. Since a cutting board with a roast on it is horizontal, and melted paraffin flows downward thanks to gravity, you would not likely get any on the roast, or at least not enough to notice. If the surface of the hot roast is wet (juicy), as is usually the case, wax won’t adhere to it anyway, and in any case, that wax is nontoxic.

Still, I should point out that paraffin is generally used not on serving boards, but on butcher’s chopping blocks, mainly used for cutting cold, raw meat, where the surface is all end grain. For a serving board, or even a flat grain cutting board, I’d go with boiled linseed oil.

I make lawn chairs for neighbors and family. I use pine lumber because of cost and put clear varnish on for finish. After a year or two, the finish fades or peels. Someone told me to spray chairs with the clear finish they use on cars. Can I really do that? Look forward to your reply so I can make more durable items.

– Paul Liput

Hacienda Hills, California

Yes, you can spray wood with automotive clear coat, but I think you have a larger problem than that will solve.

Pine is not an ideal choice for exterior furniture since it moves a lot, contains a lot of sap, is rather soft and, unless it is pressure treated, has no natural resistance to bugs or rot. If you really want to make more durable items, start with a wood that has good exterior durability (mahogany, white oak, red cedar, ipe, redwood, cypress, teak).

To get back to your specific question, there are plenty of finishes that will work on pine, but do make sure you check the wood’s moisture content before finishing, and let it dry if it is above 12%. Finishing wood that is too wet is an invitation to peeling.

A good exterior clear varnish or spar varnish should hold up more than one year, but not much more. Other options include deck coatings, which need almost yearly renewal, exterior house paint (over primer) if you want a solid color, or even, as someone suggested to you, automotive urethanes. Nothing will hold up very long, so your choices are between something that holds up a little longer, or something that is easy to rejuvenate.

In my retirement, I anticipate creating woodworking projects such as multi-species cutting boards, wooden bowls, wooden spoons, etc., etc.

I have completed several of those cutting boards for a couple of my granddaughters and finished them with mineral oil with the assumption that they would be food-safe. Through normal use, the boards have needed a refurbishing. My question is: Am I correct in my assumption? Or would it be better (and food-safe) to use the boiled linseed oil instead of the mineral oil? If I can use the linseed oil, can I apply it directly over the mineral oil presently on the boards without presenting an adhesion or curing problem?

– Herb Fogelberg

Woodbury, Minnesota

Yes, and no, in that order.

Yes, you can use boiled linseed oil on a cutting board. It is food-safe once dry, and it will hold up a lot longer than mineral oil, though not forever. You can replenish when needed.

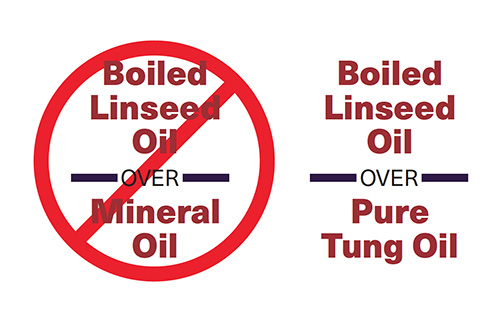

No, you can’t go over the mineral oil, since that never dries and you can’t put a drying finish, like boiled linseed oil, over a non-drying or still wet finish. To redo the board you’ve already done, first remove the mineral oil by scrubbing the wood with mineral spirits to solvate the mineral oil, then blotting it up with paper towels. Get as much oil out as possible. Follow up with a scrub using an ammonia based cleaner, such as Windex®. Ammonia is a surfactant, meaning it will help “grab” that last bit of mineral oil.

When the wood is clean and dry, sand it smooth, then flood it liberally with boiled linseed oil, re-wetting the surface wherever the oil is absorbed. After 10 or 15 minutes of flooding, wipe off all the excess oil and let the board cure in a warm, dry place for two days before putting it into service.

Incidentally, drying oils, like linseed oil, may not cure over woods in the dalbergia family, so if you plan on using anything from the rosewood family in your multi-species boards, leave those natural.

I have built a dining room table using bamboo flooring that I planed down to a uniform thickness. I glued it to a 36″ x 54″ top and sanded down to a 500-grit paper. I finished with five coats of tung oil, using 4/0 steel wool between coats. When we put a coffee cup on the table with a coaster, it raised up the tung oil and also raised up the grain on the wood. I thought maybe I didn’t wait to cure the oil.

After reading your column, I noticed noticed that the author leans to boiled linseed oil — and his tung oil shows “100 percent pure tung oil.” Do I need to sand off my tung oil down to bare wood, or can I apply BLO on top of the tung oil?

– Marvin Steffen

Alford, Florida

I’m going to assume you are certain that your flooring was pure bamboo with nothing else in it. Otherwise, this may be a different issue entirely. You might be dealing with resin or waxes added to the bamboo “boards” during manufacture, which could affect how oil dries and cures. Let’s assume you have untainted bamboo and move on to the finish. I don’t know what was in your “tung oil” product, but if it did not dry completely, you want to remove it, even if you must resort to paint remover. First, though, try scrubbing it with mineral spirits on a nylon abrasive pad. That should remove any uncured oil. You won’t have much luck trying to sand oil off: sanding liquid oil simply grinds it into the wood and moves it around.

You can certainly go over cured tung oil with linseed oil, but that’s not what I would suggest in this case. For a dining room table, which gets lots of wear and plenty of heat and stains, I’d go with an oil-based polyurethane varnish. It, too, can go over any cured oil. Just clean and scuff sand for adhesion first.