At first, there was the roadwork. Today, Jim Van Etten is a highly respected furniture designer and builder with a great following, critical acclaim and plenty of work for his four-man shop, Furniture by Design, but strange as it may sound, it all began with paving.

Jim’s family owned a road construction business. Like any dutiful son, he went to school and got an AA degree in civil engineering from State University-New York (SUNY), then spent the next 10 years working in the family business. It was the nature of the business, though, that led him to stray.

“I had winters free, thanks to the weather,” Jim recalled, “and that opened the door to woodworking. I had an interest in woodworking, but don’t really know where that came from. My grandfather had a small shop, and I think I may have started playing around with wood in his garage. I got a few tools, and with no knowledge, started building things during January and February from 1977 through 1979.”

About the same time, Jim discovered the spate of new woodworking magazines and specialty woodworking stores that showed up in the mid-to-late 1970’s. “That started me on a path of education,” he explained. “It was the emergence of tool stores and woodworking magazines that first offered the information and education I needed.” Soon, more formal schooling followed.

“In 1980, I went to a three-day wood symposium in Bucks County, Pennsylvania, run by Albert LeCoff, where I heard lectures by Tage Frid, Ian Kirby and others. I was thoroughly excited and signed up for a one-week, intensive summer workshop in cabinetmaking and furniture design at Kirby Studios in Vermont. I came back from that in August and decided I wanted to change my life, so I went back to Kirby’s school full-time to become a furniture designer and maker. My family was unhappy about it because they assumed I was going to take over the business. Instead, they put the business up for sale, but for me, the die was cast.

“I stayed with Kirby for two years. During my third year, which was supposed to have been my last, I decided instead to rent space from a cabinetmaker in North Adams, Massachusetts, and started doing private commission work on my own. My relationship with Kirby was still very good, but my finances demanded that I start working again.

“I moved to tiny Spinnerstown, Pennsylvania, along with Phil Donnelly, another Kirby student, and we set up a shop in the heart of Bucks County. That area is rich in woodworking history, yet conveniently located near both Philadelphia and New York, two major cities in which to sell our output.” Jim and Phil parted ways after about six months, and Jim has been working on his own ever since. On occasion, he partners with another local cabinetmaker, Dave Wothers, to do larger jobs. His former partner Phil went to work at a local furniture company for more than a decade before finally going out on his own.

“When I started,” Jim told me, “I was primarily building commissioned pieces of freestanding furniture — tables, chairs, desks and the like. I designed a product line of modular tables and started reproducing multiples that I could take to shows and sell wholesale. In 1989, I showed at the Contemporary Furniture Fair in New York City and was on the cover of Interior Design magazine that year with one of my modular tables. That particular table could be configured in at least 30 different ways.

“That got me into some showrooms, but my experience with them was not good. I ended up getting stiffed when one of them went out of business, and I became soured on dealing with them. I went back to doing business directly with clients and decorators. That meant doing mostly architectural casework, custom work, and other larger-scope jobs. That also meant hiring others, since the jobs were too big to do alone.” Today, he and three other employees build high-end custom casework and cabinetry and specialized woodworking, which can mean almost anything made of wood.

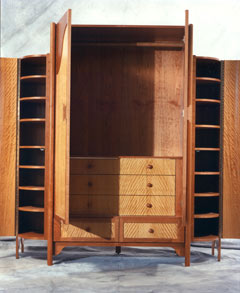

Along the way he’s made chairs, tables, cabinets, built-ins, walls, ceilings, kitchens, libraries, bathrooms, desks and doors. In short, if it’s in a home and can be made of wood, he’s done it. “At one point, we even took on a job building two dozen soundboards and cases for a local harpsichord builder.” Most of his work ends up in the Philadelphia area, where he’ll sometimes go in and do an entire home interior. For the past decade, most of his work has been fixed or built-in pieces, which become a permanent part of the house. “In many cases,” Jim explained, “people have sold homes for more than they imagined because of some of the work we did.”

“Having been in business for over two decades means my shop is filled with tools I never imagined having.” He has CNC equipment and large power tools, but because of his background, still uses hand tools regularly. “Eighty percent of the work is actually done by machinery,” Jim explains, “and 20 [percent] by hand, but that 20 percent done by hand takes 80 percent of the time. Everything goes through the machine room to the bench room, through the finishing room and finally out the door. Everyone in the shop must be able to do hand work, machine work, installation and even finishing.”

“When it comes to finishing,” Jim admits, “we do everything you taught me.” He means that quite literally. You see, Jim and I shared shop space and some tooling from 1986 through 1989, first in Spinnerstown, and then in Perkasie, Pennsylvania. During that time we taught each other whatever we knew: While I picked up woodworking skills from him, he learned finishing from me. “My three years spent with you has been a very big part of my career,” Jim insists. “Contractors regularly tell me that my finishing is superior to most. I do all my own finishing; I can do it quickly and reproduce or repair it any time in the future.

“For the past five years, I have had no problem getting work,” Van Etten admitted, “because much of my work has been published and because of the architects I work for. I was once in Better Homes and Gardens magazine and did not even know about it. Currently, all my work is through contractors and architects out of Philadelphia.”

Part of the reason for his success has to be his attitude. “It doesn’t matter who we’re working for or whether we like the person or not,” Jim insists, “we always put out our best effort and produce a quality product. I think that the profession of cabinetmaking has evolved in this country from being almost non-existent in the early 70’s to becoming a way of living a good life and making a living and sustaining yourself. This is a good thing. It is an interesting profession in which you are constantly learning, and at the end of the day, it is very satisfying to know that you have made something beautiful that was not there before. It is almost like composing a piece of music. You start from an idea and work it through.”

When all is said and done, it appears that it is the personal satisfaction even more than the livelihood that makes it all worthwhile for Van Etten. “You spend months working on a project,” he explains, “and the day that you install it and get to see the completed project, that’s a high. Sometimes, that’s better than getting paid. You sit back after dinner and you feel whole. The money you make gets spent, but the work you do lasts far beyond.”