As soon as I laid the Router Emergency Kit on the table at my guild’s board meeting, I knew I’d have to keep an eye on it. As it passed from hand to hand ,the comments ranged from, “Now, that’s a good idea; it’s exactly what I need” to the inevitable, “Can I have it?”

No wonder. The kit is a clever assortment of replacement bearings, screws, washers and stop collars for router bits. It’s the perfect solution for anyone who has ever grappled with failed bearings or incorrect sizes on bearing-mounted router bits. The kit contains 10 replacement bearing screws, four hex keys, two bearing dust shields and 13 bearings, some of which have inserts for different size bit shafts. Fortunately, I was able to stave off those tool hungry wolves by pointing out that it only costs 40 dollars, and they could easily afford their own.

As slick as it is, the Router Emergency Kit is only one of close to a thousand items sold by Infinity Cutting Tools, a relatively new company quickly making a name for itself in the highly competitive field of router bits, saw blades, shaper cutters and associated accessories. At that it is an ancillary product: the bulk of their product line covers every type of usual and unusual router bit and shaper cutter you could ever hope to find, and some innovative table saw blades as well.

In fact, it is innovation that sets this company apart from its wealth of competitors. The company comes by that honestly, because when it comes to tool design, Infinity’s owner, David Venditto, boasts a very respectable lineage. “I grew up around the wood cutting tool business,” David informed me rather modestly, adding, “My father ran a large cutting tool manufacturing company that makes saw blades and router bits.”

In fact, his father’s story is well known in the woodworking field. The former president of Freud, David’s father left to start his own company, Jesada. He came up with the company name by stringing together the first two letters of the names of each of his three children, Jessica, Sabrina and David.

“I graduated from college with an economics degree in 1994,” David recounted, “and started working for my father at the Jesada factory. He sold Jesada in 2001. I went off to Europe to work as a management consultant for an Italian motorcycle manufacturer, Moto Guzzi. After about a year, I moved back to the states to work for Jesada’s new owners, but found the company had changed dramatically.

“Meanwhile, Infinity had been created in 2003 by Corey Spann, an importer/distributor who was trying to set up a line of cutters. It never got off the ground, and Corey, whom I knew as a former employee of my father, gave me the name. I started a brand-new company around it but kept the name because it reminds me of the infinite opportunities to make infinitely better products.

“I went back to my experience in the mail order tool distribution field and fashioned Infinity into a company that designs, engineers and distributes premium cutting tools for woodworkers. That includes router bits, shaper cutters, saw blades, and woodworking accessories, like pattern door templates, sleds, and other gear that revolves around the router, shaper and table saw. We have a catalog and only sell direct, either by phone or through our web site. Selling direct and avoiding secondary distribution sites allows us to price our cutters competitively.”

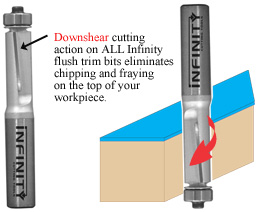

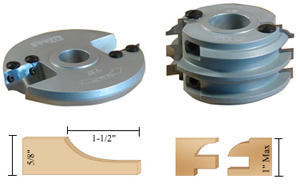

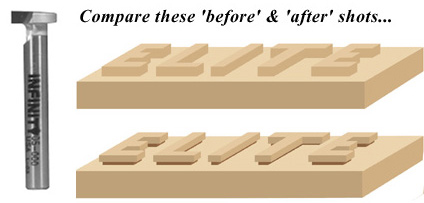

There is certainly no shortage of variety in the product line. David’s catalog is awash with cutters that make you say, “I didn’t know you could buy that.” Things like flush-trim carbide spiral cutters, specially sized wing cutters for fitting odd thickness plywood panels, trim cutters with both a top and bottom bearing, replaceable insert cutters, rabbet cutters with multiple bearings and a host of cutters to make things like box joints, finger joints, floating letters, beads and coves, and just about anything your heart desires. The same sort of variety is available in their shaper cutters, too, but they don’t stop there. One of the products David is proudest of is the Dadonator, a whimsically named eight-inch dado set that occupies a place of honor within his line of table saw blades.

“Our Dadonator has won multiple awards from several magazines,” Dave announced proudly. “The outside blades are nickel-coated, which prevents moisture from entering the metal plate, thus preventing rust and pitting and extending the life of the blade. Nickel also adds lubricity similar to the Teflon® some companies apply to their blades. Inside are six-tooth chippers rather than the more common two- or four-tooth ones. The chipper is more solid with a larger plate and more mass to reduce vibration, which translates into smoother, clean-bottom cuts. The outer blades have 24 alternate bevel teeth with a 20-degree grind, a higher angle which results in less chip-out and smoother cuts in difficult woods, such as veneered surfaces. The result is a very clean, square, flat bottom cut on all types of wood and plywood.”

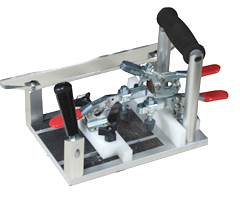

In addition to cutters, Infinity also turns their designing talents to accessories. “Our coping sled, for example,” David told me, “is a very unique product. It is a massive, solid aluminum, CNC-machined eight-pound router crosscut sled. That combination reduces vibration, is safer and makes for more accurate repeat cuts. The sled has a comfortable, ergonomically correct handle, three 500-pound toggle clamps and a Lexan® safety visor that runs against the router table fence. The Lexan not only protects you from flying debris, it also keeps the base of the sled away from the spinning router bit. On some coping sleds, the base itself runs against the fence, allowing it to come in contact, albeit accidentally, with the bit. This sled makes cross grain or cope cutting fast, safe and easy.”

David’s pride in both his products and his background are understandable. “I know of no other web distributor that has the sort of experience in the field that we do,” he insists. “That experience allows us to design superior cutting products. Our customer is the quality-conscious hobby or pro woodworker. We don’t target those looking for throwaway bits. We use the best carbide, high quality resilient steel that will not break or crack, and the best shear and cutting angles devised to ensure clean, burn-free cutting. Simply put, our tools yield a cleaner finish and have a longer life.

“The only thing that exceeds the quality of what we make is our customer service. It is one of the pillars of our existence. We return calls, return emails, address any concerns our customers have, and offer a lifetime guarantee on everything we sell. We’ve had a lot of praise for our attitude and approach, and that is critical to us. The bottom line is that our customers have learned to trust us to provide superior quality and service, and we try to meet that expectation every day.”