Measure twice and cut once is still good advice for the novice woodworker, but having cut a board too short is only one reason to lengthen it by scarfing. You may need to cut out an area of rot, sapwood, a large knot, check or shake. Most damaging are the type known in England as Thunder Checks. These are hairline cracks running across the board at right angles to the grain. At one time they were thought to be caused by thunder, but careless felling is the real culprit.

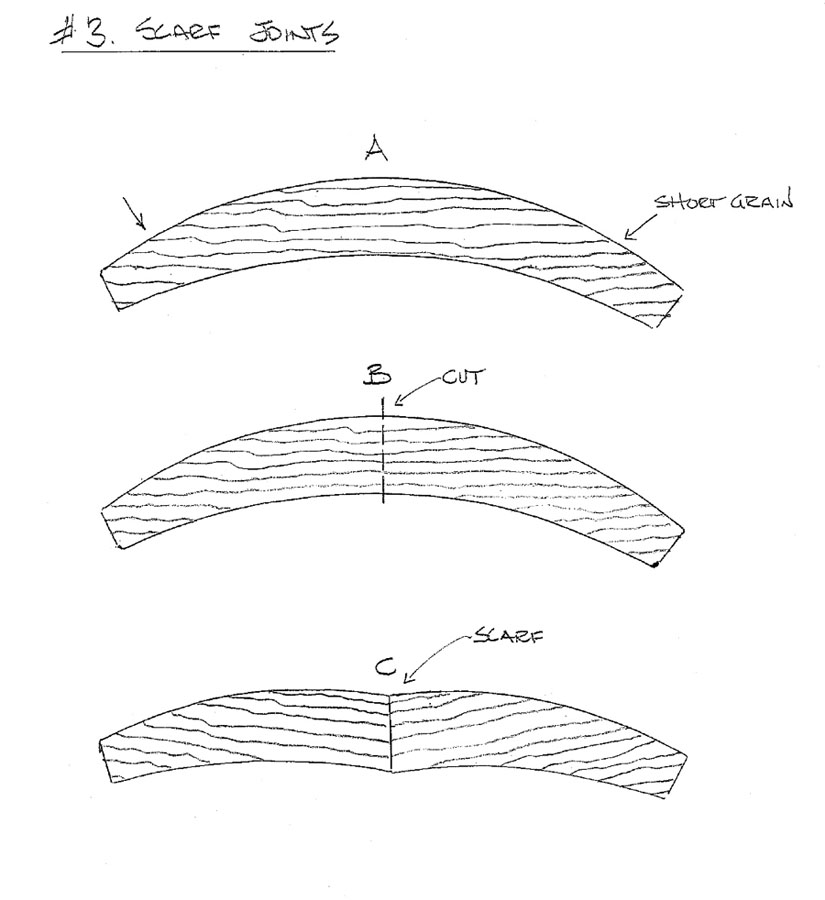

Boat builders often find that a plank might have so much shape that they must start with unreasonably wide boards, which is wasteful. If a plank is too banana-shaped, the short grain at each end weakens it. (A) A common solution is to cut the plank in half, (B) then scarf the two halves back together at a slight angle — 10 degrees or less (C).

I always cut and glue scarf joints first and plane the plank to its finished thickness only after the glue has cured. This trick is useful with solid wood but is not an option when scarfing plywood.

I always cut and glue scarf joints first and plane the plank to its finished thickness only after the glue has cured. This trick is useful with solid wood but is not an option when scarfing plywood.

The usual formula for the length/thickness ration (slope) is 8 to 1. Making the scarf longer adds little strength, but short scarfs will fail — especially when subject to bending. With only a few scarfs to make it’s just as quick to plane them by hand. (E-G) With a dozen or so, it’s worth making up a jig and cutting the scarfs with a router.

If you plan to plane the finished join — either by hand or machine — make sure that the grain direction is consistent from one end of the board to the other. The glue I prefer is Balcotan — a Swiss-made version of Gorilla Glue.