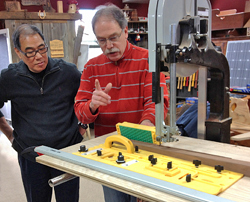

Before Henry Wang emigrated to Florida from Hong Kong in the 1970s, his varied career had been about as far from the woodworking products industry as one can get. He had been an importer and exporter of textiles, worked for the airliner Cathay Pacific and even exported sturgeon fish for a while. Coming to America was a dream, and when the opportunity presented itself, he took it.

Once here, Henry changed his business cards once again — this time to restaurateur. “Our family opened the first Chinese buffet in central Florida,” says Bruce Wang, Henry’s eldest son and team leader at Micro Jig. “And Dad has always had a constructive spirit about him. When he’d see a need for something at the restaurant, he’d try to build it.”

Henry’s woodworking pursuits included building buffet tables with Formica® laminate tops, and creating a semi-circular jig that made it easier to close the lids of aluminum take-out food containers. When Henry needed to drill holes more accurately on his drill press, he fashioned a marking gauge to make the process easier.

“As a woodworker, Dad has always focused more on creating practical tools and apparatuses than making furniture,” Bruce admits.

Then, in the late 90s, Henry sold the restaurant and, for a time, didn’t know what his next career path would be. One day while tinkering in the workshop and pondering his options, he decided to make a cutting board from wood strips culled from the scrap bin. A problem surfaced during the process: he could only cut a few of strips from each workpiece before the “keeper” board became too narrow to rip further. But, what remained still seemed too big for Henry to toss out. It felt wasteful to him.

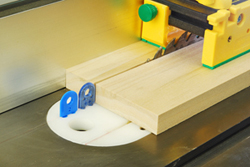

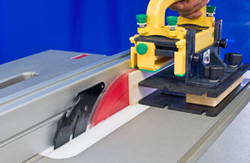

“Dad realized that if he could make a jig that could straddle both the keeper piece and the offcut, he could get a few more strips from each piece of wood,” Bruce recalls. So, necessity truly became the mother of invention. Henry’s cutting board project was the impetus for developing the first GRR-Ripper 3D Pushblock, now considered one of the more innovative safety products that have come to market in our industry in the past dozen or so years.

It took Henry about two years to refine his GRR-Ripper design, and Bruce says there were some 45 different variations that Henry experimented with during that time. But, the product had real merit: to Henry, it truly was a better way to feed narrow stock through a blade than any other push stick alternative he could find. “Dad spent tens of thousands of dollars in capital pursuing patenting and production capability for our GRR-Ripper … that was a real challenge for a guy supporting a family with two kids and a mortgage.”

In 2001, Henry incorporated Micro Jig and sought an exclusive distributor for the GRR-Ripper. The former JoinTech was first to take on the product and demonstrate it nationwide on the woodworking show circuit. When JoinTech went out of business, Peachtree Woodworking was Micro Jig’s next principal dealer. Henry also developed relationships with Rockler, Lee Valley and other key woodworking product suppliers to create a dealer/distributor network. That effort has, over the years, blossomed into some 250 retail outlets that sell Micro Jig products.

“Dad was my hero growing up, and since this is a family business, I’ve really been part of Micro Jig since the start,” Bruce says. “I’ve always appreciated the American ethos of making things happen, and I watched my humble father live that dream. Growing up, I would deliver our orders to the post office and help with assembly sometimes, too.”

But Bruce, who admittedly has a more outgoing nature than Henry, pursued a college degree in business and marketing. While in school, he opened his own financial practice and continued to help out at Micro Jig when he could. Then after graduation about five years ago, he came on board with Micro Jig full-time.

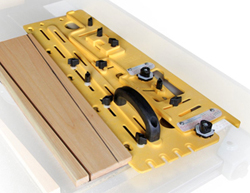

Through the years, the company has expanded its product offerings, and they’re all designed by Henry. Micro Jig offers aftermarket table saw splitters, a new GRRR-Rip pushblock, a micro-adjustable Microdial Tapering Jig and and an expandable Zeroplay Guide Bar for miter gauge slots. The company’s payroll has expanded, too, with several more in-house staff and a dozen salespeople across the U.S. But fundamentally, Micro Jig is still a family company. Henry continues to focus his energies on product design, his wife Amy manages the finances, and Bruce handles sales and marketing. Recently, Bruce’s younger brother Calvin, an electrical engineer, joined the company to oversee data analysis of new products “and to generally bring an analytical mindset to what we do … he’s a great addition to our company.”

Looking back on the origins of Micro Jig, Bruce feels his father’s ingenuity is sometimes misunderstood. “People think the GRR-Ripper 3D Pushblock was invented as a safety product, but it actually came about because Dad wanted a better way to feed the wood through the blade and produce less waste. Safety was actually a byproduct of his design, but of course, it’s a good one.”

Up to that time, “there was just so little innovation in advancing and feeding wood … I think that’s because woodworkers often stick to methods of work out of tradition. It takes a lot of mental energy to innovate, even something as simple as a push stick. You have to be both in and out of the craft to be able to see what it needs. That gives someone like my dad the ability to see things with fresh perspective.”

Bruce says that despite Henry’s ingenuity, he’s an introvert and a careful spender. “During the recent recession, Dad invested almost nothing on advertising. But products don’t sell themselves. People in companies do. So when I came to work full-time, I knew we had great products and the infrastructure to produce them. What we needed was to really go after the business.”

And Bruce took on that challenge in a big way. Micro Jig stepped up its marketing efforts, worked more directly with dealers to conduct in-store demos and redesigned its website. Active, engaging videos and improved photography were added to help end users better understand product applications. Bruce also began to re-brand Micro Jig’s packaging from plain boxes to more descriptive and eye-catching containers. The cumulative effect of those efforts, Bruce says, has been “record sales and growth” over the past four years.

One aspect Micro Jig has remained committed to since its inception has been American manufacturing. All Micro Jig products are designed in-house, and they’re made and warehoused in Miamisburg, Ohio, as well as in the company’s Winter Springs, Florida, headquarters.

Surveying the company’s current product offerings, Bruce says that while the GRR-Ripper 3D Pushblock system is the “lifeblood” of the company and far and above its best-selling product, his favorite Micro Jig innovation is the new GRR-Rip Block. It’s a push block for the table saw, jointer or router table with a soft, textured base pad and drop-down hooks that fit over the edges of a workpiece. They retract when the push block is used in the middle of a board instead of along its edges or ends. “The GRR-Rip Block is so simple and intuitive, and it builds directly off of the success of our GRR-Ripper system.”

Will MicroJig’s wheelhouse of innovative products ever expand beyond workpiece handling and safety? “Probably not,” Bruce speculates. “We want to continue to help woodworkers work smarter and safer with better material handling products. It’s an area where fresh ideas can really disrupt the industry in a positive way.”

“Other woodworking accessory suppliers have gone after all sorts of products to expand their lines, with mixed amounts of success. But, I think it’s better to know what you’re good at, and stick to it. Don’t deviate too far from that, and it will help you keep true to your mission and stay out of trouble in the long run.”

To learn more about Micro Jig, click here. To see of a recent AWFS video of Bruce explaining Micro Jig’s new Microdial Tapering Jig, click here.