When handsaws had wooden handles, they were sold with the handles able to move in relation to the saw blade even when the fasteners were tight (unless some clerk in the store mistakenly decided the handle should not move and tightened the screws). I always thought the ability of the handle to move in relation to the blade was to help relieve or lessen wrist fatigue. But now, having seen quite a few handles split along the grain, I believe they were loose in relation to the blade to help prevent splitting along the grain due to seasonal movement of the wood. Of course, a lot of newer saws have handles made of other non-wood materials and they come from the store with the handles secure to the blade with no movement. What is/was the reason the handles were able to shift slightly? – Arthur Morris

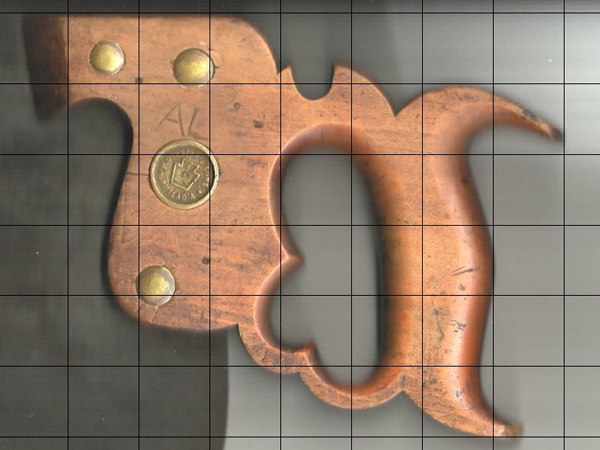

Ernie Conover: I have collected and used handsaws since I was a teenager. Adkins, which were made in Indianapolis, are my favorite, but Disston saws are very good too. Saws made up until WWII were well made, sporting good steel and ergonomic wood handles. Good saws had handles of apple wood, which is very difficult to split. The saw blade had holes punched in it. The saw nuts, which held the handle to the blade, had a male and female half and were secured with a pair of straight blade screwdrivers, one on each side. The holes in the blade were oversize to allow a good deal of production variation and for seasonable change of the wood handle. The blade slid into a groove in the handle and the saw nuts pinched the two sides of the handle tight on the blade. If the saw was not to move in the handle during sawing, the nuts were brought up tight. Even with the nuts very tight, the oversize holes still allowed for seasonal changes in the wood handle.

In the heyday of saw manufacture, all wood was air dried. The nuts were probably loose at the hardware store because the wood handle dried further during transportation and its time in inventory. The user would tighten the nuts before using the saw. This is all to say that I have seen no great spate of cracked handles on saws made prior to WWII beyond fair wear and tear.

Saws became increasingly dismal after the war, with handles that were afterthoughts. They were not ergonomic and even painful to use for any extended period. Carpenters finally left their handsaws at home to gather dust in favor of an electric worm gear or sidewinder circular saw. Today, almost all saw handles are plastic, and most blades have Japanese style teeth. I bet the wood-tote saws you are asking about are pre-war.

Tim Inman: I’m both a former hardware store owner and a lifetime-long woodworker and furniture restorer. Old tools are my favorite thing to work with. That said, I have no hard answer for your question as to why the handle, or tote, was not tight. For my own use, I want the saw blade fixed tightly in the handle. I do not want the blade moving around any place unless I direct it to go there! A loose blade can develop a “lead” or a mind of its own and go awry. I don’t like that. For precision work, I want to be the driver at all times. Wood does move, and wood does split. As a merchant, I would probably not object to loose blades on my displays that would not split their handles. I would expect the craftsperson to adjust the saw and handle to suit their own purposes after they left my store.