I recently purchased a bunch of clamps from an estate sale; however, they have a slight coating of rust on them. Most of the clamps are sliding bar F type. What’s the best way to remove the rust? – Jim Haviland

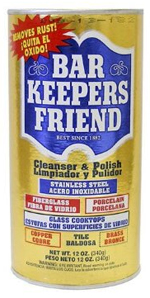

Tim Inman:There are any number of rust removers on the market. They are all acids as far as I know. Each has its own supporters. Unless you’re really into the flaky, clumpy rust, I’d suggest a simple product like Bar Keeper’s Friend®, available on the cleaning supply shelves at just about every supermarket and discount store in the free world. It will clean the metal of light rust. Then, while you’re in the household cleaning supplies department, look for a product I’ve used for years to keep my tools and tops pretty rust-free, a crystal clear acrylic floor polish, sold by one manufacturer as Pledge® FloorCare Wood Finish. It is a water-based acrylic preparation. Wipe it on, it dries, and it leaves an almost imperceptible film of acrylic to shield the metal from moisture and rust. If you’re a gilder, water-based gold size will do the same thing — at a greatly increased cost! Both are acrylic emulsions. Plus, when you wax your tools to make them slick, the acrylic base seems to just love it. Best of both worlds.

Chris Marshall: As Tim says, there are probably woodworking supporters of every rust removal product on the market. Being a creature of habit, I tend to “go with what works” most of the time. I’ve mentioned this product previously for other rust questions, but I like a spray-on product called Rust Free by Boeshield. You spritz it on, wait a few minutes, then wipe off the rust with an abrasive pad. Works great, but wear some protective gloves when you use it. Follow that up with a coating of Boeshield’s T-9® protective spray, which if you click here, comes in the same three-piece kit. That should take care of the light rust on your clamps. But, stay on top of it — no matter how we treat it, rust has a way of sneaking back onto tool surfaces now and again. Perspiration, wet sponges, high humidity … you get the drift.