Scott and Gin Wayland-Smith are now the second generation to be building wooden spoons and other utensils in Montana. It’s a business they took over last year from Gin’s father, Bill Edwards, who started out as a sawyer cutting trees for logging companies.

“About 20 years ago, he wanted a way to get out of the woods, and started making wooden spoons,” Scott said. Bill had grown up in the Ozarks area of Missouri, and those first spoons he made were of a “very rough” tradition from that area, scratched out with hand awls, Scott said.

Over the years, though, Bill had refined the spoonmaking process — and Scott and Gin continue to do so as well. They try various methods to “find a little bit different way of doing things,” Scott said. “Ninety-five percent doesn’t work, but the other five percent makes things go a little faster or a little better.”

One aspect of their woodworking they want to keep, though, is the hands-on aspect. Their spoons are not created with a lathe or a duplicator, although they do use a band saw and power sanders. “We’re constantly running our hands over the wood, to feel what we’ve done,” Scott said.

Their process begins when Scott buys the lumber — a 120-mile one-way drive to find the correctly sized stock. After bringing it back to their shop, he does the outlines and rough cut, Gin does the basic rough shaping, Scott does the bowls, and they work together on the finish sanding.

“We work side by side in a 16 x 17 foot shop with three ’employees’,” Scott said. Those “employees” consist of a yellow, a chocolate and a black Labrador retriever. The yellow one is evidently the taskmaster, who starts barking every morning at 6:30 to tell Scott and Gin “it’s time to get to work,” and will also bark at them if a coffee break extends beyond about 10 minutes.

The coffee break, for now, would occur in the guesthouse Scott and Gin are living in on their 15 acres in northwest Montana; they’re in the process of building a 1,000-square-foot log home. One of the “tools” Scott has used in that building is a wooden dipper in which he discovered a flaw in the wood halfway through the building process — he adapted it to use for building, as a digger of dirt in small spaces a shovel wouldn’t reach.

In most cases, the big dippers are Scott’s favorite product to make. “It’s one piece of wood, with the handle and bowl integrated together. It’s the hardest to make, but when it’s done, I sit there and stare at it for five minutes. It’s the hardest to do, but my favorite when it’s done.”

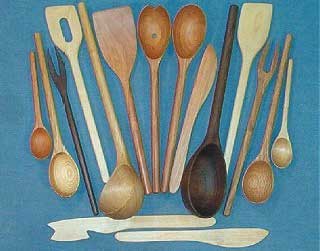

In addition to the spoons, dippers and ladles they make for sale through their family business, Scott and Gin have also created custom-made utensils for themselves, such as a barbecue set, and for their five children. “We use nothing but our own wooden utensils for cooking,” he said.

Those products aren’t part of the business in part because they can be more labor-intensive: on a good day, Scott and Gin can produce four spoons, and other items take even longer. Scott says, however, “I like to think we do make the finest handcrafted wooden spoons in the country.”

He’s also proud that they use only American-produced hardwood, with his favorite being walnut — he appreciates the dark look of it when finished. For hickory, he works hard to find “two-tone” examples, with light and dark swirls. The one wood he’s found that does not work well for their spoons, though, is oak.

Scott hadn’t worked with hardwoods prior to his entering the family spoon business last year — he had been a mechanic for General Motors for 20-odd years, but, he said, always with a love of working with wood. “As soon as I left the job, I didn’t go home and tinker with cars; I went home and remodeled houses.”

His life now, he said, is “basically the American dream. My wife and I get to work right next to each other, we get to stay home, we live in the mountains of Montana. I wouldn’t have it any other way.”