Why would a company that makes asphalt roof coatings, furnace cement and masonry sealants get into the wood finishes business? Surely Gerald Payne, who founded United Gilsonite Laboratories (UGL), must have asked himself this very question at least once back in the late 1950s. That’s when the company prepared to bring its first wood finish to market. To an outsider, it seems a bit of a product stretch.

But as the story goes, Payne was committed to meeting the needs of the do-it-yourselfer, and that objective drove his company’s expanding product line. In fact, when he started UGL in 1932, Payne turned a salvaged sausage grinder into a mixing machine to blend his Gilsonite roof coating product himself. He didn’t just support motivated DIYers; he was one.

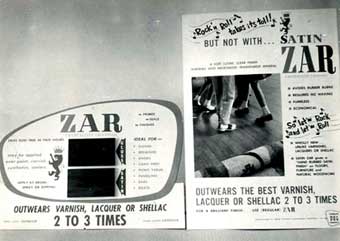

And so, in 1958 UGL introduced ZAR® Crystallite Coating, one of the first polyurethane clear finishes available to the American DIYer. Prior to this point, poly had been used as a commercial coating in the furniture and automotive industries, but Payne saw it as a safer alternative to the flammable shellac, varnish and lacquer options of the day. Urethane resin also offered higher solids content plus better flexibility when cured; both characteristics would improve durability.

For Payne, consumer-friendly polyurethane was clearly a good idea whose time had come. Time has certainly proven that he was on to something big. Judging by the overwhelming popularity of polyurethane among woodworkers today, Payne was also a visionary.

In the half century that’s passed since the first Crystallite hit hardware store shelves, UGL has become an industry leader in polyurethane varnishes and has greatly expanded its ZAR product offerings. Today, the company provides nine different formulations of interior poly and two options of exterior finish. UGL manufactures oil- and water-based, wiping and quick-drying formulations, Environmental Formula Product, stain/poly blends and a high-solids “Classic” variation. The ZAR brand also includes lines of oil- and water-based stains and colored wood filler.

Even though UGL has a diversified wood finish line, ZAR probably isn’t the first name that comes to mind when you think of poly or stain. That’s probably due in large part to the fact that ZAR wood finishes aren’t sold at major home centers. UGL chooses instead to distribute to co-op hardware chains like Ace, True Value and Do It Best stores, as well as Sherwin Williams dealers. Recently, I asked Michele Neary, UGL’s Public Relations Director, what sets ZAR finishes apart from the “big box” competition.

“UGL’s greatest attribute is quality. We may not be as big or as well-known (as other brands), but our quality is unrivaled. UGL is a privately held company…We do not have to skimp or sacrifice to benefit shareholders. Because there is not all the red tape, chemical manufacturers know if they want to bring new technology to the market they can introduce it to UGL chemists and decisions can be made quickly and effectively. This is why UGL is able to be the first in many areas of technology.”

Michele explained that in the case of polyurethane products, for instance, the company uses only ASTM Type 1 resins — the highest quality urethane resins available. Varnish formulations also include a higher solids content than some brands to ensure maximum performance.

One of the technological “firsts” on which the company prides itself is its new line of Ultra Max polyurethanes. Unlike typical oil- or waterbased finishes, Ultra Max consists of oil-based resins suspended in water. It is a waterborne oil-modified polyurethane that cures as the water and solvents evaporate and the resins coalesce and crosslink. What’s the benefit? Michele says the varnish cures from the top down and the bottom up simultaneously, which accelerates “to the touch” drying time to as little as 30 minutes. And faster curing time is just what the on-the-go woodworker is looking for these days.

Aside from speedy curing, this dual-drying technology brings greater confidence to the finisher as well. “When Ultra Max feels dry, it is dry,” Neary says.

Ultra Max is also available in waterborne oil-modified wood stains. This product is purported to offer deep, rich color similar to oil-based stains, and it needs no initial wood conditioner to prevent blotching. Its consistency is closer to a gel than a liquid.

Ultra Max is one effort UGL is making to comply with stricter governmental VOC regulations within the finishing industry. While other companies may be forced to compromise quality to meet VOC guidelines, UGL is able to innovate. Neary says UGL constantly monitors governmental environmental activity as well as trends and advancements in resin development. This put them in a proactive and “cutting-edge” position when developing Ultra Max.

“Many manufacturers were scrambling to get something to market, and others decided not to comply and went out of business.”

Regardless of stiffer governmental regulations, woodworkers still demand certain characteristics from their coatings and stains. That keeps the R&D process lively and challenging for companies like UGL. Michele says we’re asking for minimal grain raising and warm, amber tones from our varnishes. We demand sufficient open time to lay the finish down but fast curing to minimize contamination problems. And, of course, durability is always a premium. We also want our varnish sheens and wood stain colors to be consistent from can to can. UGL is focused on meeting these sorts of requirements. Michele admits that’s it’s been a tough balance to keep, but one in which the company feels successful so far.

“Most woodworkers take great pride in creating a piece of art; they take time in the design and craftsmanship of the piece. The finish is the icing on top of the cake…so there will be no guesswork with our products. Our gloss, satin, semi-gloss and antique flat sheens will always be the same, and our wood stains will match from batch to batch to batch.”