Wood movement. You don’t have to be a woodworker for long before you’re confronted with it. A flat piece of stock one day takes a twist the next. A tight glue joint in summer opens to a hairline crack the following winter. And your new “green” turning goes from round to oval almost faster than you can get the bowl off the lathe.

Wood’s hygroscopic nature — its tendency to absorb and release moisture with changes in humidity and temperature — is the primary reason that wood moves. It makes wood uniquely and yet frustratingly enigmatic.

But Delmer and Ed Wagner have been doing their best to help woodworkers of all levels cope with wood movement for almost 50 years. Delmer, originally a sawmill electrician and then an entrepreneurial businessman, founded Wagner Electronics back in the mid ’60s because he saw the need for a better “systems” approach to measuring wood moisture levels in lumber mills.

“Delmer was both intelligent and practical,” says Ron Smith, Wagner’s Meter’s sales manager. “Back in those days before circuit boards, he cannibalized old TV tubes to make his first moisture meters.”

For a few years, Wagner’s early meters were built and sold on a modest scale, with Delmer establishing his clientele, taking orders and even assembling the meters himself. His sensor-based system that followed was different from handheld meters that were carried from board to board: lumber in the mill would move over plates that would evaluate moisture content as it passed through the processing stages. It was a significant step forward in technology, because unlike typical moisture meters, it didn’t rely on sharp pins being driven into the wood to take readings. Wagner’s approach sped up the procedure and wouldn’t leave marks behind. In fact, Wagner Meters has never designed or manufactured “pin style” meters.

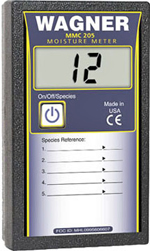

Delmer’s son Ed, who grew up in the family business and went to college to study electronics, invented the company’s first handheld electronic moisture meter. “It was Ed,” who now owns the company, “that really pushed our product line to go from analog style pinless meters back in the mid-’90s into digital readout. He also developed our IntelliSense technology,” Smith explained. IntelliSense is Wagner’s proprietary innovation that enables the meter to differentiate between surface moisture on the wood and the percentage of moisture content through its thickness. “Other meters at the time were very sensitive to surface moisture, which would cause them to give inaccurate readings. IntelliSense set our meters apart from others, because you could get a true, full-thickness reading regardless of surface moisture.”

Wagner Meter’s success in the large lumber industry got noticed elsewhere. Eventually, wood flooring manufacturers came to Wagner for a solution to evaluate moisture content in concrete slabs. These days, the company continues to serve lumber mills as well as the wood flooring and concrete industries. But woodworkers know Wagner as a leader in pocket-sized digital moisture meters for the home and professional shop.

And in this context, Ron has some advice to share about controlling moisture content in our own lumber inventories. First, to minimize wood movement, you have to determine the equilibrium moisture content (EMC) of the wood when it comes into the shop. That takes a moisture meter as well as knowing what the temperature and relative humidity are in your shop. EMC is influenced by both of these factors.

Second, Smith says you have to create a controlled shop environment. To do that, you may need to humidify or dehumidify the shop from season to season or based on where your shop is located (dry garage, wet basement, etc.). Otherwise, it’s difficult to regulate EMC in the wood stored there.

“Generally, for indoor projects, you’re aiming to achieve an EMC of about 6 to 8 percent in the wood, and you need to figure out how to achieve this percentage by modifying your shop temperature and humidity levels.” Installing a hygrometer and thermometer in the shop can help establish a baseline so you can learn how the conditions fluctuate.

But if you live in an arid environment like Salt Lake City and build a project that will end up in New Orleans, EMC might need to change. Six to 8 percent might not be the optimal percentage after all. “Whatever the EMC tends to be where the piece is going to live is what to aim for in the EMC of the lumber you use to build the project,” Ron says.

He also recommends a modified approach to how lumber should be stored when we receive it. If the wood is immediately “dead stacked” one board on top of the next — a typical practice for most of us — it will take much longer to acclimate to the shop environment unless the EMC is already close to what it needs to be. Adequate airflow all around each piece of wood is important, even if that means stickering it for a while or standing it on edge.

“And don’t assume that lumber that’s kiln-dried is at the 6 to 9 percent moisture content you want,” he adds. That’s where a moisture meter is the only way to know for sure. He recommends taking moisture readings on every board to account for variations that may occur from piece to piece. When taking readings, repeat about every 18 inches of board length and meter from both faces of the board. Never take moisture readings of end grain. Wood loses moisture about ten times faster through its end grain; scan or insert the meter’s pins into the face grain or, if pin pricks are unacceptable, take readings from the edges of the stock instead. Avoid lumber defects such as knots, which can also give incorrect readings.

Until the day comes when lumber is synthesized from a lab instead of harvested from a tree, wood movement is going to be a reality for us. But a good moisture meter can help evaluate it so we can work to minimize its effects. Wagner innovation is helping to make the process both easy and accurate. For more information about wood moisture metering solutions, visit the company’s website by clicking here.