If you’re a trim carpenter by trade, and if you pride yourself on doing high-quality work, here’s a tip of my hat to you. You folks are the unsung woodworkers of the world.

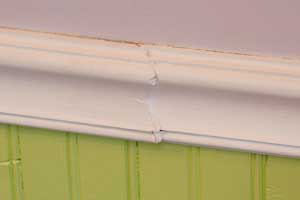

I say this partially out of plain-old respect for the building trades, but also because my house is missing your expertise. This past summer my wife and I finally got around to painting our daughters’ bedrooms. I was in charge of “cutting in” around windows, doors and ceilings, so I spent quite a bit of time examining the moldings along the way. Let’s just say that the trimwork in those two bedrooms left a lot to be desired. To illustrate my point, here are several photos documenting what I saw up close. As you can see, the mitered window casings aren’t even close to touching. The chair rail in one bedroom has a scarf joint smack-dab in the middle of the wall, and were it not for copious amounts of putty, you could drive a small truck through it. What an eyesore.

Maybe the fellow who installed these casings just “eyeballed” the measurements. Or, maybe my house suffers from some weird malady of shrinking woodwork. I’ll never know why or how the trim got to this stage, but I can tell you one thing for sure: it’s coming down soon.

I suppose it’s true with trim carpentry that the best workmanship goes unnoticed. I would guess that the causal observer rarely admires an airtight miter joint or the perfect return on a window stool. Never mind the more complicated jobs like crown installation or stair-building. Those details blend into the general scenery of a room. But, a really bad trim job sticks out like a sore thumb, especially to a woodworker.

So, one of these weekends, when I’m prying those moldings off the wall, I’m going to remember all of you good trimmers out there. Quietly getting the job done right, the first time and on budget. You guys are great woodworkers, and you deserve a pat on the back now and again. Here’s one from me. Keep up the good work!

Catch you in the shop,

Chris Marshall, Field Editor