One of the luxuries of being a woodworking magazine editor is that I get my hands on “good” wood on a pretty regular basis. Clear, straight cherry and maple are often “on deck” for projects in our magazine. Recently, I built a couple of Arts & Crafts bookcases from some nice quartersawn white oak for our first “Small Shop Journal” project (February 2013 print issue). And, without spilling the beans prematurely, I just finished a project that I built from some extraordinary ribbon stripe mahogany for our June issue. It was too wide to fit my jointer … what a problem to have, right?!

One of the luxuries of being a woodworking magazine editor is that I get my hands on “good” wood on a pretty regular basis. Clear, straight cherry and maple are often “on deck” for projects in our magazine. Recently, I built a couple of Arts & Crafts bookcases from some nice quartersawn white oak for our first “Small Shop Journal” project (February 2013 print issue). And, without spilling the beans prematurely, I just finished a project that I built from some extraordinary ribbon stripe mahogany for our June issue. It was too wide to fit my jointer … what a problem to have, right?!

Last fall, when I needed a few 2x4s for a home improvement project I was working on, I went to Lowe’s to pick them up. There, at the top of the pile, were a few of the clearest, straightest 2x4s I’ve ever seen. Some were even quartersawn — and for a woodworker that’s pretty mind-blowing when you consider how absolutely green, checked and awful so much of the construction lumber seems to be these days. It’s a wonder it even passes inspection on the way to market.

So I bought 10 of these beauties, for no real purpose besides not wanting to imagine them ending up in wall, hidden away forever. I suppose it was a bit greedy of me, but I couldn’t help myself.

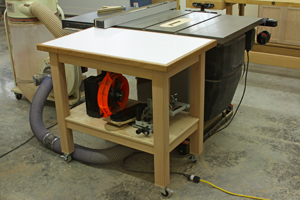

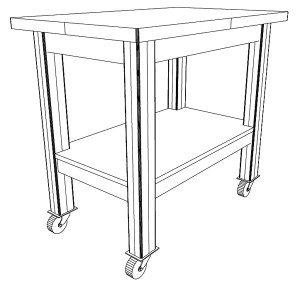

Well, one of those shop projects I’ve had on my “to do” list for a spell has been a simple work table that I could put behind my cabinet saw to use for outfeed support. The saw is close enough to my planer that I figured it would serve the second purpose of staging stock as I surfaced it. Simple enough. Who can’t use another little table?

One Saturday afternoon I drew up a plan for my little shop table, and then it occurred to me that I really didn’t have any “good” stock I could use for the framework. After all, surely I must have leftover hardwood laying around from some project or other that would do the trick. I went out to the shop and, rummaging for the lumber, actually moved those nice 2x4s out of the way to keep searching.

Then the Homer Simpson moment hit me: “Duh, use the 2x4s, Chris. Why not?”

Well, here’s the back-of-my-mind reason: They’re JUST 2x4s.

I should be ashamed not to have thought of them right away. They turned out to be the perfect choice for this little project. I glued them up into leg blanks, cut some mortises and whipped this table together the very next day. The top is actually a simple project we shared some time ago in an online router technique. If you didn’t see it then, click here for a link to it.

I should be ashamed not to have thought of them right away. They turned out to be the perfect choice for this little project. I glued them up into leg blanks, cut some mortises and whipped this table together the very next day. The top is actually a simple project we shared some time ago in an online router technique. If you didn’t see it then, click here for a link to it.

Now, there’s not really a moral to this little story. But the experience has reminded me that there can still be some diamonds in the rough of what you can find in the home center lumber racks. And, even a few “lowly” 2x4s can turn out to be something pretty nice in the end. My little table will remind me of this every time I have cause to move it around the shop. I might even cruise the racks at the big boxes now and again, just to see what might be hiding there. You never know.

Speaking of which, if you’ve made some projects from “ordinary” construction lumber that your particularly proud of, leave a comment and tell us about them. Maybe we can start a 2×4 renaissance.

Catch you in the shop,

Chris Marshall, senior editor