I’m finally coming around from the self-induced food coma of Christmas Eve and Christmas Day. The wrapping paper is waiting in a big bag for the next run to the recycling center and, for the most part, the gifts are put away.

I’m finally coming around from the self-induced food coma of Christmas Eve and Christmas Day. The wrapping paper is waiting in a big bag for the next run to the recycling center and, for the most part, the gifts are put away.

It sure comes and goes quickly, doesn’t it?

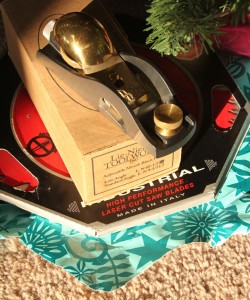

But, during this little lull between Christmas and New Years, and before these big holidays are entirely behind us, I want to put the brakes on for a minute. Seems like a perfect opportunity for us to reflect on the cool things we made and gave away as gifts. Or, maybe someone left you something particularly shiny and sharp under the tree this year. A new handplane or dado set, perhaps? Maybe some great new gizmo from your favorite woodworking supplier—or just as nice, a gift certificate to said supplier?!

So, tell us, whaddja give? whaddja get?

I’ll start with me. About a month ago I posted that my wife wanted something to hang her earrings on. She suggested that a frame of some sort with screen inside would be just the ticket. She could hang it on the wall and see all of her earrings more easily instead of digging through her jewelry box to find them. Seemed like a pretty clear request to me, and a fun little project to make. So, I built two frames of the same size and style for either side of her vanity mirror. But, I made one from tiger maple and the other from some particularly figured cocobolo I was saving for a special purpose. The corners are half laps. The ends of the joints extend a little beyond the frames, and I shaped them into elongated pyramids. I found some brass screening online and experimented with West System epoxy to secure it into shallow rabbets.

I’ll start with me. About a month ago I posted that my wife wanted something to hang her earrings on. She suggested that a frame of some sort with screen inside would be just the ticket. She could hang it on the wall and see all of her earrings more easily instead of digging through her jewelry box to find them. Seemed like a pretty clear request to me, and a fun little project to make. So, I built two frames of the same size and style for either side of her vanity mirror. But, I made one from tiger maple and the other from some particularly figured cocobolo I was saving for a special purpose. The corners are half laps. The ends of the joints extend a little beyond the frames, and I shaped them into elongated pyramids. I found some brass screening online and experimented with West System epoxy to secure it into shallow rabbets.

They were quite a hit on Christmas Eve.

It’s really fun to make someone exactly what they want—and play with some fancy wood in the process.

I didn’t get any good stuff for my shop, but I did get a new camera lens that should come in real handy on future magazine articles. Guess I was a good boy after all this year.

I didn’t get any good stuff for my shop, but I did get a new camera lens that should come in real handy on future magazine articles. Guess I was a good boy after all this year.

Now it’s your turn. Please tell us about your holiday project successes. Go on, brag a little! It’s okay. Or, make us green with envy about a new tool you can’t wait to start using.

I really hope you’ll fill us in!

Catch you in the shop,

Chris Marshall, Field Editor