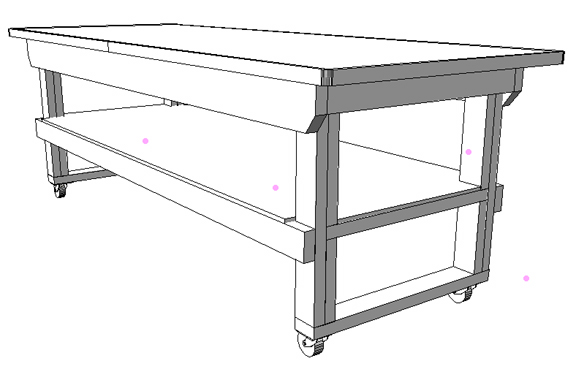

A couple weeks ago, I reported on my trusty old, cosmetically challenged workbench. The goal, really, was to support those of you out there who are more concerned with utility in your shop fixtures than high style. In other words, you build sturdy workaday shop fixtures so you can get on with more important projects. And, that’s okay in my book; I do it, too.

Well, a few of you were interested in building one of these workbenches for your shop. And, some even commented that it’s just as “legitimate” a workbench as something that could cost a lot more money or be more exactingly designed.

Thanks for the kinds words of support, and even the soft admonishing. You’re right: a bench that works is a workbench, after all. And they take many forms.

So, I’m going to return the favor. If you’d like make one of my workbenches, you can get a set of measured drawings, step-by-step instructions and a material list in PDF form by clicking here. There’s no cost or hidden strings attached. Call it a little gift from me to you. Make it to match mine, or change it up any way you see fit. There’s no right or wrong here, that’s for sure.

Now, and I do mean this honestly—this bench shouldn’t take you more than an afternoon to build. If it does, you’re working too hard at it! Once it’s built, you don’t have to treat it with kid gloves, either. After all, it’s just 2x lumber, MDF and screws. Still, this big ol’ bench has held up well for me for ten years now, as simple as it is. I hope it gives you just as many years of “helping hand” with your woodworking.

Now, and I do mean this honestly—this bench shouldn’t take you more than an afternoon to build. If it does, you’re working too hard at it! Once it’s built, you don’t have to treat it with kid gloves, either. After all, it’s just 2x lumber, MDF and screws. Still, this big ol’ bench has held up well for me for ten years now, as simple as it is. I hope it gives you just as many years of “helping hand” with your woodworking.

Catch you in the shop,

Chris Marshall, Field Editor