How can you tell if the board is twisted? With winding strips.

Your board has edges that are square to a flat face. You know because you checked it with your square — but how can you tell if the board is twisted? There is only one way: with winding strips.

When a piece of wood is twisted (its ends are out of alignment), woodworkers describe it as being out of wind. This is also known as planar alignment. To check to see if your stock is twisted, you need a set of winding sticks. Winding strips come in pairs and are parallel-sided straight pieces of wood of the exact same dimensions. They are not readily available though commercial channels, so you will need to make your own. In days gone by, the preferred wood for this task would be Cuban mahogany. Sadly, it is long gone, but Honduras mahogany will do nicely. The goal here is to use a truly stable material — so any clear and dry, straight-grained, quartersawn hardwood would serve well.

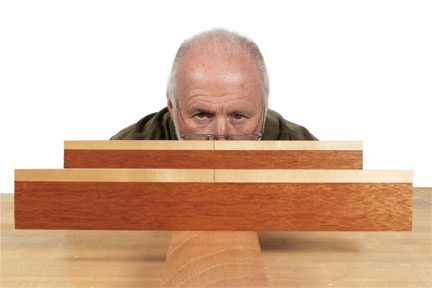

As you can see in the examples shown, a lighter colored wood glued to the edge provides a nice sighting line to work from. As long as they are accurately made, it does not really matter if they are very fancy (with inlay and contrasting species) or plain. The center marks are essential as you must line them up as you sight the work.

The dimensions of the winding strips shown are 3/8″-thick, 2 1/4″-wide by 14 1/4″-long. The maple strips laminated to the top edge taper from 7/16″ down to 3/16″. But there are no set sizes for winding strips. You can make them to a variety of widths and lengths to support your fashion of woodworking.

To use the winding strips, set them at right angles to the length of the board. Start with the winding strips at the opposite ends of the board, align the center marks and then sight across the strips as shown in the photos. If the board is twisted, you will be able to see it right away. A board may not be out of wind along its entire length, so move the strip at the far end of the board toward you in a few spots along the way. If you find that a section of the board is not twisted, mark that section off and cut it free. Now you can flatten the remaining stock with a plane (or on the jointer for that matter) to remove the twist.