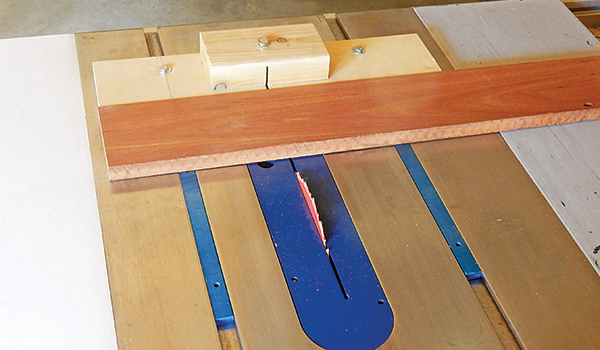

Table saw miter gauges are OK for crosscutting short workpieces, but they aren’t stable for long stock — as designed, they cantilever bad. I think I’ve improved on the concept by using both miter slots! I simply attached two aluminum miter bars to a long hardwood crosspiece with bolts and screws, then attached a block on top to act as a blade guard and extra support (the metal disk on top is a rare-earth magnet for storing the fence). My fence jig adds dead-on square precision, plus more stability, when crosscutting long workpieces.

– Bill Wells

Olympia, Washington