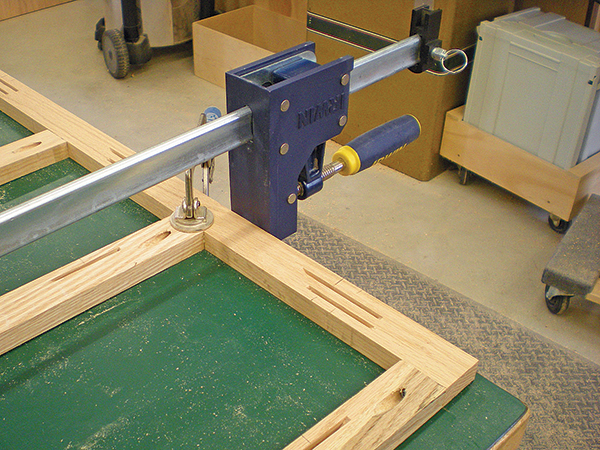

I’ve found that the round-pad quick clamps for holding pocket screw joints together don’t always keep the workpieces flush during assembly — and that can mean a lot of sanding to flatten them after you draw them tight. Here’s a simple fix: Install a second bar clamp laterally across the joint. With both a quick clamp and bar clamp in place, the parts won’t shift when you drive the pocket screws.

– Dan Martin

Galena, Ohio