Tricks of the Trade

-

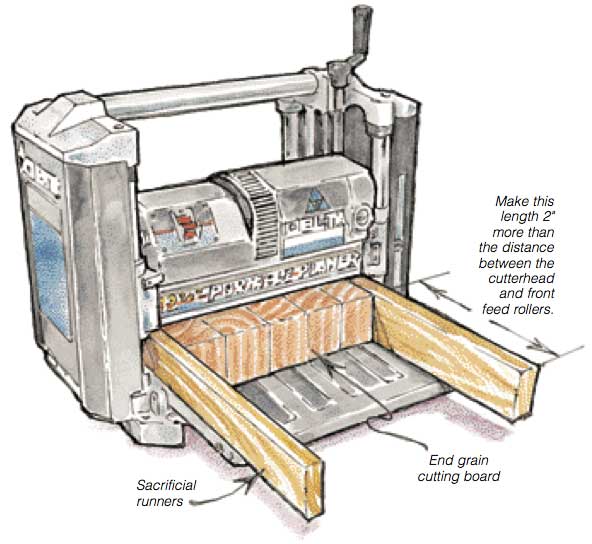

Planing End Grain

The rotating knives struck the leading edge of the board with such force that it came flying out backwards, breaking several bones in my left hand.

-

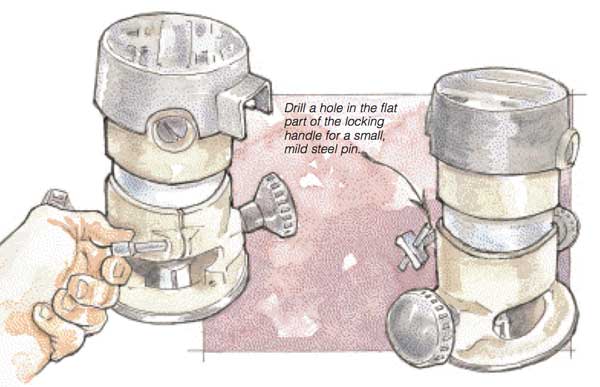

Router Helper

Tightening the locking ring on routers is hard on the hands – especially when groping around under a router table.

-

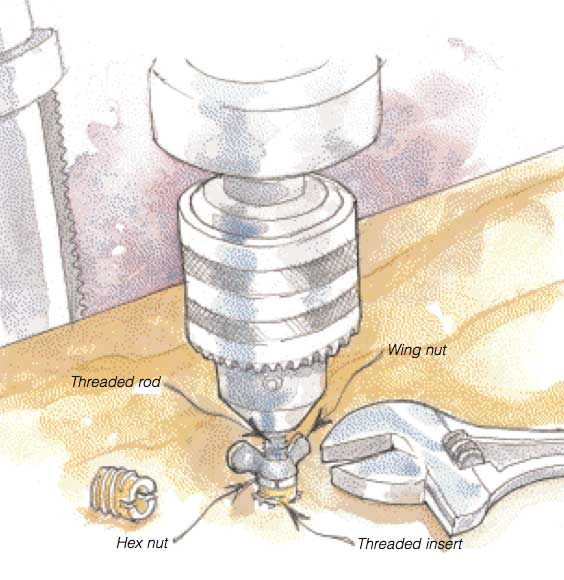

Installing Threaded Inserts

I can’t be the only woodworker that has trouble installing threaded inserts – even with the special bits provided.

-

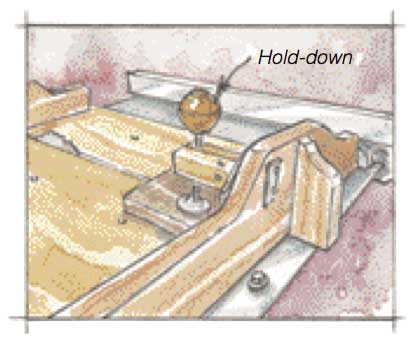

Table Saw Hold-down

I like to use a table saw sled when my work requires an accurate, 90° cut.

-

More On Magnets

Automobile speakers have strong magnets and can usually be picked up at wrecking yards for little or nothing.

-

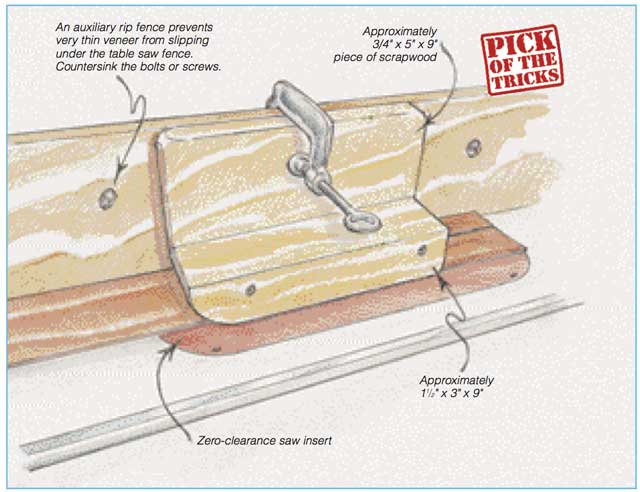

Cutting Thin Wood on the Table Saw

I make Shaker oval boxes using thin bands of wood. Cutting these pieces on the table saw without some type of hold-down is dangerous so I came up with this version of my own.

-

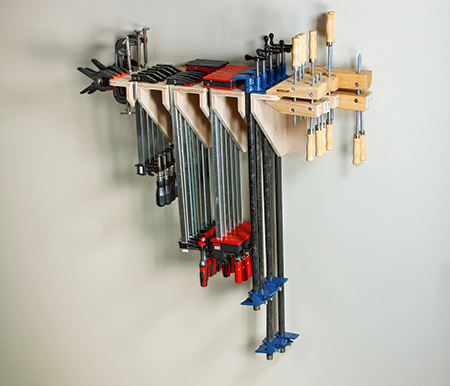

Shotgun Approach

One seldom has enough clamps around the shop for a major glue-up.

-

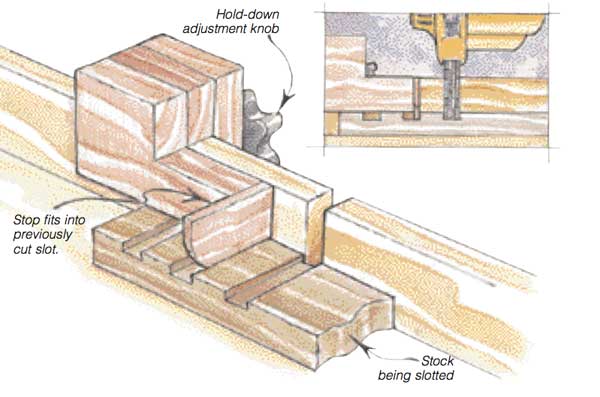

Cutting Uniform Slots

I use this moveable stop to cut a series of evenly spaced slots with my radial arm saw.

-

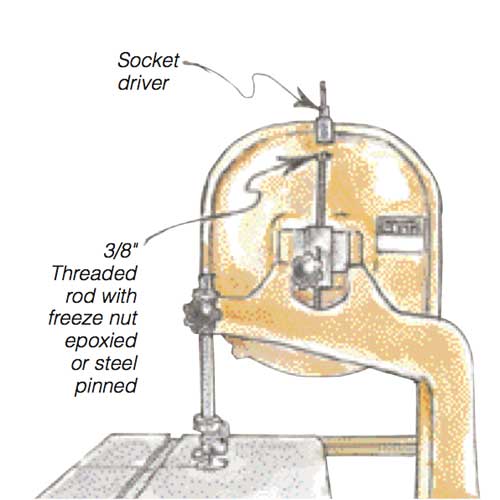

Band Saw Tension Release

It seems I’m not the only woodworker to find tensioning and releasing band saw blades a chore.

-

Wax Repair Method

Another use for candle wax.