Often, small things can have a large effect. When the Greene brothers designed a house, no detail — light switch cover, the designs on the ceramic tiles, the fabric on the upholstered chairs — escaped their focus. In that frame of mind, we’ve provided a way for you to make some small things that might add just the right touch to your room or house. Making an outlet cover from a specific wood species that matches your base trim or floor can take an unsightly afterthought (the standard plastic cover) and transform it to a nice-looking accent.

A CNC is just the machine to make a bunch of identical pieces, so we’ve provided the .tap files and the .crv files as a free download.

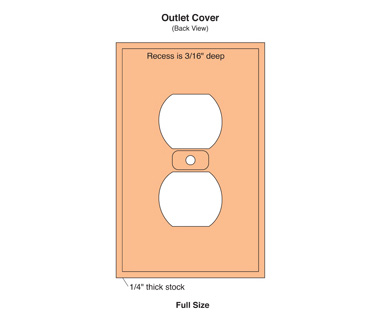

We have also provided a PDF file of an actual size outlet cover that you can print out and use to make a template if you’d like to do the job manually.

The cover is machined from 1/4-inch stock, and all the cutting happens on the back of the wood. If you want to shape the front of the cover, you will need to do that after it is made on the CNC.

Almost any species of wood will work for the outlet cover. We used Western red cedar for the outlet cover in the photo above, and even that easy-to-fracture wood held up well for the process. A word to the wise: these wooden covers will not be as strong as their plastic cousins. It would be a good idea to make a few extra just in case one or two are accidentally broken over the years.