We tend to think of spindles as round, but it is often necessary to leave flat spots.

In some cases, a spindle may have four sides left square. Most table legs have a section at the top called the “pommel,” left square to accept the aprons. Some table and chair legs also have square sections near the bottom to accept stretchers.

Most newel posts have a square section at the top to accept the railing, and also a section at the bottom to accept a rail into which the balusters are mortised. Turned bedposts need a square section into which the rails are mortised or bolted.

On wingnuts, ratchet paws and other mechanical parts; wooden forks and spoons; and tool handles, you will often find two sides flat.

One side may be flat on a chair stretcher, to serve as a footrest, or on the plug for the mouthpiece of whistles and recorder flutes.

These variations on the theme are what I call “flat round” work.

Work Sharp

In turning spindles that have portions left square or flat, the importance of sharp tools cannot be overemphasized! Spindle tools, like the roughing-out gouge, spindle gouge, skew chisel and beading and parting tools, have to be just as sharp as bench tools, with long bevels in severe 25° to 30° angles. Tools that are less than keen and/or have short bevels will make leaving flat or square portions much more difficult by causing ragged and chipped edges.

In flat/round work, precise layout saves time and material. It is the key to getting everything right the first time around. Jointed stock that is cut to uniform squares or rectangles is imperative.

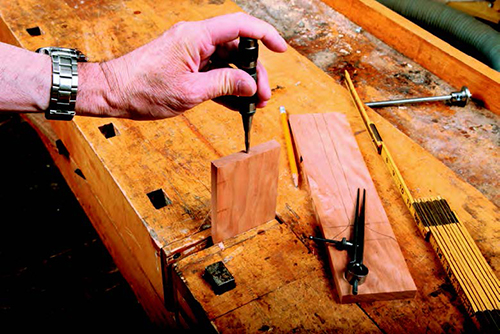

For spindles with areas left square, it is just a matter of accurate centering on each end when mounting the blank. The easiest way to accomplish this is by scribing diagonal lines between the corners. This method works equally well with slightly rectangular stock.

For things like screwdriver handles or forks and spoons, using a marking gauge and dividers is the surest way to find center on both ends.

Lathe Speed

Enough, but not too much, speed on the lathe helps greatly in making the transitions from square to round. For 2″ square and smaller spindles, 1,000 to 1,800 rpm is appropriate; however, the higher end of this spectrum is for the experienced turner with a heavy lathe.

The beginner, using a lighter lathe, is well advised to stay closer to the 1,000 rpm speeds. For 4″ square and larger spindles, speeds between 500 and 800 rpm are better, depending on lathe and experience.

The Transition

The difficult part of leaving an area square focuses on the shoulders, where the transition occurs. This transition can take three different basic forms. (You can watch me make these three cuts in my More on the Web video.) As with learning any new technique, practice makes perfect, and testing these various forms is best done on scrap lumber rather than on your prized stock intended for project use.

Shouldering the Burden: The Most Difficult Area

It only stands to reason that if you have a flat area on a round spindle, there is an area where the round changes to flat (or vice versa). This is called a transition, and there are three basic ways to form the transition — each can be modified to suit the turner’s aesthetic.

A hard square shoulder transition is most commonly encountered in table and chair legs. The best tool for this is the skew, presented with the toe down and the edge absolutely vertical. The handle must be angled such that the appropriate bevel is 90˚ to the work, making it kiss the shoulder throughout the cut.

For a half bead shoulder, the cut is made with a spindle gouge after first making a square face with a skew. It is a half bead, rolled mostly on air. It makes an elegant transition and is used mostly on table legs, bedposts, new posts and balusters. It is helpful to draw a pencil line a set distance from the square face to give yourself a starting point.

The cut for a half cove shoulder is done entirely with a sharp spindle gouge. It differs from a half bead cut only in that it is a cove instead of a bead. Either is cut mostly on air. The trick is to start with the handle low and touch the bevel of the gouge to the work. Slowly bring the handle up until the edge just cuts. Now, roll the bead.

Safety Consideration

For some flat work, such as salad forks, it is often easier and safer to use the band saw to remove excess material. Square and flat work well advised to stop the lathe when moving the tool-rest or the banjo. And for the same reasons, it is a good idea to completely remove the toolrest during sanding.