The butt joint — edge gluing two pieces of wood together to make a wider panel — is one of the three primary woodworking joining techniques used in furniture making. And doing it with hand tools is very practical.

Making the Joint

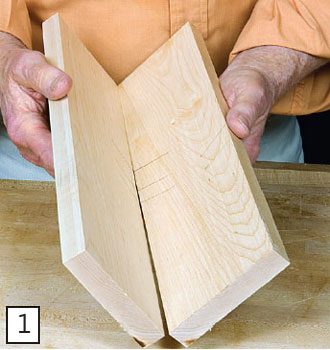

1. To begin the process, simply take two adjacent boards and fold them together as though they were hinged at the intended joint. This imaginary “hinge” can be either side. Then go ahead and clamp the folded pair together in a vise to get them ready for the plane. Mark the face of the boards so you can keep their orientation as you go through the process.

2. Use a jointing plane (an 07 plane is perfect but other long bed planes will work fine) to plane the paired edges so they are flat in length and width. Use proper technique and have the plane set for a fine cut to produce fine (.003″) shavings.

3. Checks may be made with a straightedge alone because if the paired edges are flat across their thickness, they need not be square. That’s because the out-of-square angles on the two boards will cancel each other when you remove the boards and stand one edge on the other. Nevertheless, try to go for square as well, and check the paired edges with a try square.

Checking the Joint

Check 1: Rotate the top board back and forth; you will be able to feel the contact as the two faces rub one another down their length when you have the joint right. If the joint is high in the middle of the board, the top board will rotate easily around the high spot. You must remove the high spot if it is present.

Check 2: Pull down hard on one end of the top board and see if and where it lifts from the lower board.

Check 3: Just look at the joint. If contact looks good by gross inspection from 9″ to 12″ away, then put your eye right on the joint line about 1/2″ away. Light will reveal any gaps in the joint line.

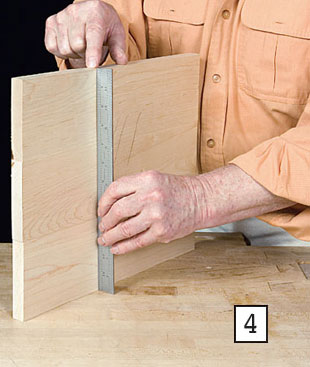

Check 4: Stand the boards on end and check their alignment with a straightedge. The panel should be flat. You can take out a small bow later by planing the entire panel flat, but any large deflection should be removed before glue-up. If all these checks show the joint to be sound, go ahead and glue and clamp the panel together.