This article, “A Beginner’s Shopping List, Turning Tools and Sharpening Gear,” by Walt Wager, is from the pages of American Woodturner and is brought to you by the America Association of Woodturners (AAW) in partnership with Woodworker’s Journal.

After I purchased my first lathe, I started shopping for turning tools. I bought a set of high-speed steel (HSS) tools from a mail-order store. The set included a 3/4″ (19mm) spindle roughing gouge, a 1/2″ (13mm) bowl gouge, a 3/8″ (10mm) spindle gouge, a diamond-shaped parting tool, a round-nose scraper, and a 1″ (25mm) skew. Since I didn’t know much about turning, these were what I used to get started. After joining the AAW, I read many articles about tools and how to use them. If I had to do it all over today, I would purchase individual tools (instead of a set) to get more flexibility and choice for the money. This article describes the various tools I would recommend for a new turner.

Traditionally, turning tools were made of carbon steel, and it is not uncommon to find these tools in garage sales, auctions, and as giveaways with used lathes. Turning tools sold today are almost all HSS, which is tougher than carbon steel and holds an edge longer. However, not all HSS steel is the same: there are differences in quality among the various manufacturers and vendors. These differences are discussed in Alan Lacer’s 2008 AW article, “Testing the Steel in Turning Tools.” Most turning tools today are made in England or China. Look for tools designated as M2 steel. M2 HSS contains tungsten and molybdenum, which give it toughness and wearability. Lacer implies in his article it is better to stick with established vendors and manufacturers, as opposed to buying cheaper tools often available on online auction sites. But he also notes that some of the tools from discount vendors meet the quality standards of the more expensive versions.

Turning Tools

What turning tools do you need? It depends on what you plan to turn. If you are only going to turn pens, then get a set of tools made for penturning. However, for general use for everything from spindles to bowls, I’ll give you my opinion and why I’d choose these tools, preferably in M2 HSS.

1″ Spindle Roughing Gouge

The spindle roughing gouge is used for roughing the corners off square spindle blanks to bring them into round, forming cylinders and tapers, and making smooth planing cuts. This tool is relatively easy to learn with practice.

Safety Note: As the name implies, the spindle roughing gouge should be used only for spindle work—when the piece is mounted between centers with the grain running parallel to the ways of the lathe. It should never be used on a bowl or other workpiece mounted with the grain running perpendicular to the lathe bed. While this tool has a relatively large cutting edge, it also has a short, weak tang (the part inserted into the tool handle). Crossgrain work such as bowls present endgrain to the cutting edge, and the spindle roughing gouge is not made to withstand the associated forces. The tang could break, resulting in serious injury.

3/8″ Spindle Gouge

This is a highly versatile tool for spindle work. The tool’s shallow flute aids in forming beads, coves, and V-groove cuts with crisp corners and transitions.

3/8″ Bowl Gouge

An all-around tool used mostly for facegrain work (with the grain running perpendicular to the lathe bed) but also suitable for some spindle-turning tasks. As its name implies, the bowl gouge is typically used to shape the outside of a bowl and to hollow a bowl’s interior. Its deep flute and longer, swept-back wings (a grind option commonly found on bowl gouges) allow you to remove a lot of wood in one pass. If you plan to turn many bowls, you might also want to purchase a 1/2″ bowl gouge for larger work.

3/4″ Square and Round-nose Scrapers

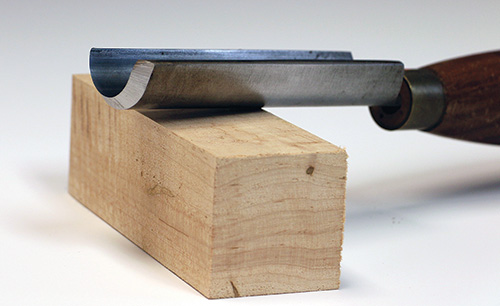

Scrapers are useful mostly for smoothing out tool marks and for hollowing endgrain. The traditional grind is flat across the top surface, with a 40° to 45° bevel.

I sharpen my scrapers with a “negative rake,” meaning a secondary bevel is ground on the top surface downward to meet the primary bevel. Many turners are now opting for negative-rake scrapers, citing a better quality of cut with less tearout.

Parting Tool

A versatile tool used not only for parting work off the lathe, but also for making fillets and forming tenons for holding work in a scroll chuck. There are many types, shapes, and thicknesses of parting tools, but a flatsided, 1/8″- (3mm-) wide by 3/4″-high tool is the one I use most.

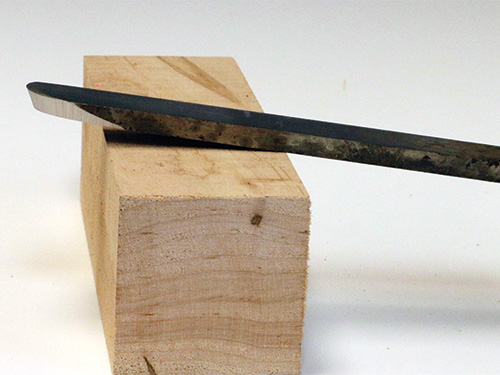

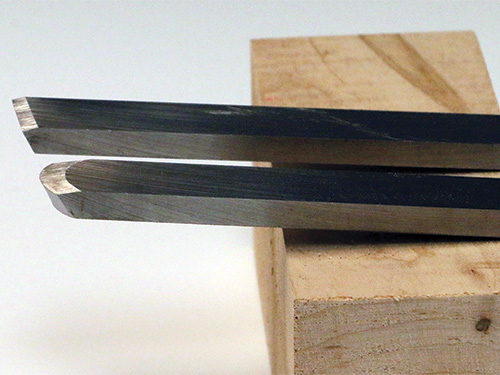

3/8″ Bedan

Not commonly sold as part of a set of tools, the bedan is nonetheless effective for roughing spindles and hollowing small boxes. The tool’s shaft is ground to a trapezoidal shape, with the top surface wider than the bottom, giving it relief as it enters a straight-in cut. It can be used like a skew for planing cuts, like a parting tool for forming tenons, and as a shearing tool or scraper. This versatile tool works much like a square-tip carbide tool.

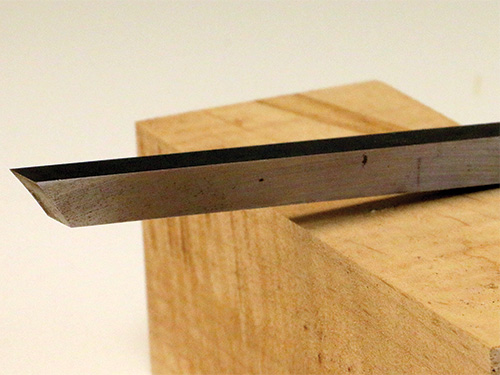

Skew Chisels

The skew is a traditional spindleturning tool useful for many of the same purposes as a spindle gouge. It is especially useful for planing cuts and forming cylinders and tapers, but can also be used for roughing and removing a lot of material quickly with a peeling cut. This tool has the reputation of being difficult to master but is well worth your practice time.

Skews come in various sizes and configurations, but a 3/4″ skew is a versatile choice.

Sharpening Equipment

Turning tools do not always come preshaped or presharpened when you buy them. Some vendors offer to sharpen them for an extra fee. If you are a new turner, this is a good idea, as you will get a tool ready to use and you will know what it is supposed to look like. Even so, you are going to have to sharpen your tools at some time and will need a system for sharpening.

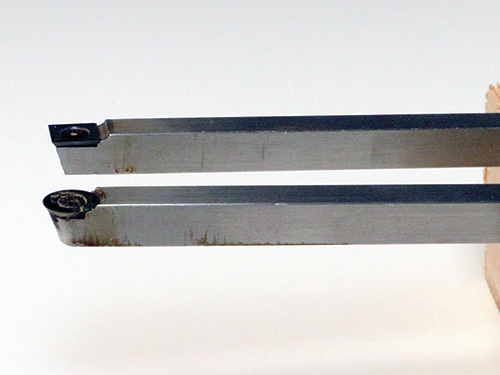

Tools with Carbide Inserts

Sharpening turning tools can be a frustrating and difficult task for many new turners. Some vendors have responded by offering tools with presharpened, replaceable carbide cutter inserts. Many experienced turners would not recommend carbide tools because traditional tools generally provide a better cut surface on the wood, more flexibility with types of cuts, and a lower cost over the long run.

But for the new turner, carbide tools may be a good choice for getting started. I teach a lot of new turners, and I like the idea that by using carbide tools, they can learn to turn and finish a project the very first time they turn. I show them the difference between the cuts you can make with carbide tools and traditional tools. Traditional tools almost always result in a better cut surface, so many of my students move from carbide to conventional tools over a series of classes.

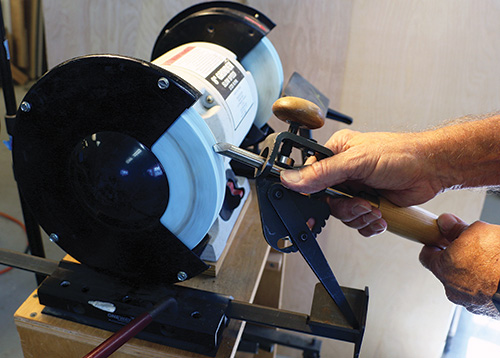

Bench Grinder with Sharpening Jig

The most common means of sharpening turning tools is with a bench grinder. You can sharpen your new tools by hand, using the toolrest that came with the grinder, but this requires a practiced hand, and it isn’t a simple matter to replicate an existing grind (bevel shape and size). To help with this task, an adjustable sharpening jig, either shopmade or commercially available, holds the tool in the appropriate position to duplicate the tool’s shape consistently.

For new turners buying traditional HSS turning tools, I recommend a slow-speed (1725 rpm), 8″ (20cm) grinder with aluminum oxide wheels. High-speed (3450 rpm) grinders with silicon carbide wheels are not recommended for sharpening HSS tools. Carbon boron nitride (CBN) wheels are especially well suited for sharpening HSS, with very little heat buildup, but are expensive and unnecessary for the new turner getting started.

If you get a bench grinder with aluminum oxide wheels, you will need an inexpensive wheel dresser, which is used periodically to clean the wheel’s cutting surface.

Diamond Hones

I recommend you acquire a set of diamond paddles or a diamond honing card. Diamond hones are used to refresh an edge on an HSS tool quickly and without going back to the grinder. Just a couple of strokes with a hone makes a big difference in how well the tool cuts. Hones can also be used to refresh the edge on carbide tools.

Note that when it comes to sharpening scrapers, preferences vary widely among turners. Many prefer not to hone at all, but to use the small burr created by the grinding wheel.

Ask for Help

Choosing turning tools and learning to use and sharpen them properly are necessary steps in becoming a woodturner. Getting help from an experienced woodturner will certainly speed up the learning process. Local AAW chapters are filled with turners who are glad to help you along. You will find a variety of opinions and methods, so listen to a number of different turners and consider what might be best for you.

Walt Wager lives in Monticello, Florida, and has been an AAW member for seventeen years. He teaches woodturning workshops at Camelot’s Woodworking Studio at King Arthur’s Tools in Tallahassee. His website is waltwager.com.