In the Q and A section of eZine Issue 361 last time out, one of our readers asked about a problem he was having with his hook-and-loop sander. Here are some other readers’ thoughts on the subject. – Editor

“In the last Q and A, Tony Barker asked about his hook and loop sander not holding the sandpaper any longer. I have had the experience of the hook and loop material coming off of the sandpaper and staying stuck to the pad. This could be a possible answer to his problem.” – Bernie Lasiewicz

“I was reading Tony Barker’s question concerning the hook-and-loop pad on his sander. Mirka recommends using one of their pad savers when using Abranet disks because the polyamide fabric on the back of the disks cuts the hooks of the pad unlike ordinary disks. Rockler sells the “pad savers,” pk of 2, $19.50, #53182. I use these and it’s well worth the investment, definitely saves the sanding pad. Been on my sander for about 6 months and pad looks and works like new. Beats spending $42+ for a new sanding pad. I use my Mirka sander with Abranet disks extensively. I do a lot of resawing, planing and sanding all week long.” – Randy B.

A Method for Folding Abrasive Sandpaper in Fourths

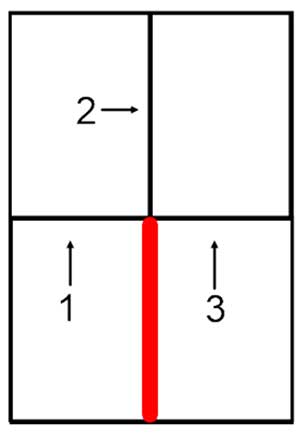

A quiz on “Sanding Secrets for Bowl Turners” in Issue 361 recommended folding abrasive sandpaper in thirds. This woodworker has a method for folding it into fourths: and he sent a diagram to illustrate it. – Editor

“In the bowl woodturning quiz from eZine Issue 361, a question asks what the best way to sand with abrasive sandpaper is. Aside from this being something of an opinion question, I gave an answer I knew to be correct, but was mildly surprised to see it was wrong. I knew that having the abrasive side of the sandpaper rubbing against itself would not be a good thing, which is what makes folding it in thirds a good thing. However, there is a way to fold sandpaper in fourths so that none of the abrasive side touches itself. The key is a quick cut along one of the sides of the fourths (as shown with the red line in the picture), and then from the back side, fold 1 up to 2, 2 over to the empty part, and then 3 up to complete the folds. It’s relatively quick and easy, and you get a more manageable piece of sandpaper to work with.” – Mike Runge

Pencil Sharpeners vs. Hard Woods

Chris Marshall’s Tricks of the Trade video highlighting Chamfering Dowels with a Pencil Sharpener has this reader remembering his dedicated pencil sharpener. – Editor

“I started chamfering dowels in my pencil sharpener several years ago. But a few years later, I found that the sharpener started doing a poor job of sharpening pencils. When I considered that pencils are made of cedar and graphite, two fairly soft materials, it became obvious that a pencil sharpener is not designed to deal with hard woods like birch, cherry, oak etc. So I bought a new pencil sharpener for pencil only and kept the old one for dowels. Also, whenever the dowel is not for show, I just twirl the end at a shallow angle on the stationary disc sander to get a rough chamfer.” – Keith McKinnon

Dissolving Gummy Tung Oil

Here’s a suggestion from another reader on the eZine Issue 361 question regarding repairing gummy Tung Oil Finish. – Editor

“To the gentleman with the tung oil problem: try using acetone, or naphtha to dissolve the gummy tung oil.” – Rick Arensmann