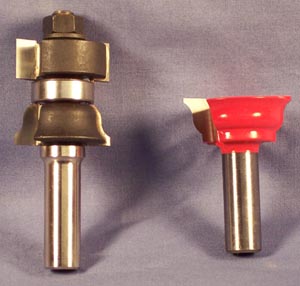

The second in our complex router bit series is the Window Sash bit set. This set is Freud’s 99-050 and 99-051 pairing. Many manufacturers make sash bits, but most are designed as ‘stub’ tenon bits, working more like a stile and rail door set. The Freud set is designed to make long tenons in the joint connections, making a vastly stronger window. Because of this, the bits require a bit more work, but the extra effort is well worth it.

Once the stock is milled to size, the parts must be cut to final length. Extra dimension needs to be added for the tenons. The tenons can be whatever size desired, based on the width of the sash parts. The stiles are the height of the window. The rails should be the width of the window, minus the two stiles, plus the length of the tenons, plus 7/16″. The muntins need to be figured as well. I found it wise to create a sample joint to verify the overall lengths.

Once the parts are cut to final dimension, The cope cuts on the ends of the rails and muntins must be made. The first steps are on the table saw. Rabets must be cut to form the tongues.

|

|

| The upper profile requires a 9/16″ deep rabbet. | Cut all of the necessary parts, then reset to cut the bottom rabbet. |

The bottom rabbet will vary depending on the thickness of your parts, but must leave a 1/4″ thick tenon.

|

|

This set also allows for making applied lights to be stuck to a single pane of glass. Keep the 051 bit low in the table, and use the coping bit to cope the ends. Also, because the 051 is made up of individual stacked parts, it can be rearranged to be used as a 1/4″ deep rabeting bit.

If windows, or a more novel picture frame are needed in your home, I hope you’ll give the window sash bit set a try. Work carefully and your work will be well rewarded.