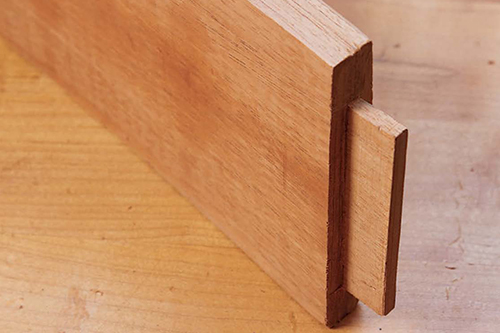

It’s time for me to learn the mortise and tenon joint. I read an article that provided the following guidelines:

1. Tenon thickness should be 1/3 the thickness of the stock being mortised to ensure the stock being mortised doesn’t weaken.

2. Tenon width should be no more than 5 times its thickness, 4″ being the max before more than one tenon should be used.

3. For a blind mortise, the mortise depth should be 2/3 the width of the board being mortised.

Using these rules of thumb on 1-1/2″ wide 3/4″ stock, the mortise would be 1″ deep and 1/4″ wide and the tenon would be 1/4″ thick and would not exceed 1-1/4″ wide. Are these good rules of thumb in real life practice?

Michael Dresdner: Yes.

Lee Grindinger: You’ve got the tenon thickness, rule number one, right. It’s simply the rule of thirds and it’s the best rule when joining pieces of the same thickness.

The point of rule two is to avoid joint failure due to cross-grain wood movement. Since most mortise and tenon joints are used in cross grain situations, the movement of wood due to moisture changes needs to be addressed. 4″ is conservative and in my real world 6″ is a more realistic maximum tenon width. Think of this rule as more of a rule of maximums. For mortise and tenons under the maximum, use what works the best.

There are times when you’ll need to deviate from these rules. An example would be where an apron is joined to a much thicker leg when constructing a table. In this instance the tenon should be thicker for more strength and farther from the top of the leg to avoid loss of strength from cutting the mortise too close to the top of the leg.