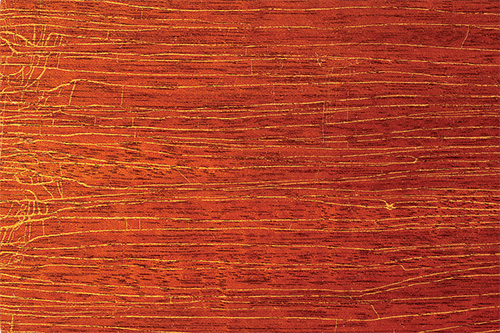

My finish, a post-catalyzed lacquer, cracks. It’s mainly on top of the veneer joint but also in other areas in the direction of the grain. The veneers are sawn and jointed via a standard 10′ Scheer veneer beam saw, and stitched together with a Haug stitcher. Then they are pressed in a hot hydraulic press using either catalyzed PVA or urea-based adhesives on top of industrial grade 11/16″ particleboard. It’s more than just the lacquer cracking, the veneer joints are being microscopically pulled apart, and the veneer itself is cracking. I have seen this same problem in the furniture of high-end retailers to the veneered kitchen cabinet doors at Home Depot.

Michael Dresdner: Some catalyzed lacquers, both post and pre-catalyzed, tend to shrink substantially as they cure, and they exert pull on the wood below. If you want to see this demonstrated dramatically, spray a plain veneer with no substrate attached and you can watch it curl up as the finish cures, or as we say, watch it “curl up and dry.” (Sorry for the bad pun.) This pull may not be enough to cause problems on solid wood, and usually isn’t, but it can crack veneers, especially if they are attached with flexible adhesives. Exploiting the weakest link, the seam is likely to go first. Though I have not tested them all, I believe there are catalyzed coatings that do not cause this problem, since I have heard from people who do not have such difficulties with their material. Also, some companies suggest using a tie coat of vinyl below the catalyzed lacquer to create a cushion to prevent this problem. As you know, sanding sealer is out of the question, since catalyzed coatings are not compatible with the stearates in it. If you can’t find a brand or process that solves the problem, consider switching to a more flexible, but still durable topcoat, such as a two-part polyurethane (either water-based or solvent-based.)