I am making a tile top table and have created the tabletop frame using butt joints. I don’t want to use mortise/tenon joinery nor dowels, but I would like to try to use splines. I want to cut the slots for the splines, either on the table saw or with my router, using a straight flute. Is this the right way of doing it? This should be a simple project for a beginner like me, but it seems to be taking forever.

Lee Grindinger: The table saw would be the best choice. There are a couple of ways to use a spline. You don’t say if your frame is mitered or butted so I’ll address both. If the joint is a 45-degree miter set your blade tilt at 45 degrees and using your miter gauge with a stop, cut a slot perpendicular and about three eighths of an inch deep into the mitered face. Use a stop block on your miter gauge so the slot appears in exactly the same place on each piece. If the joint is a butt joint set your blade at 90 degrees, cut a slot on the lapping piece 3/8″ or so deep, again using your miter gauge, and run the butting piece through the table saw on end with the support of the miter gauge. If you use the fence to determine how far from the end the dado appears on the lapping piece you can use the same fence setting for the end cut on the butt piece. Use high auxiliary fences on both your saw fence and the miter gauge for this operation. When you cut your splines be certain the grain is perpendicular to the joint for maximum strength.

Ellis Walentine: You didn’t supply many clues as to what you’ve actually done so far, so I’ll just assume that you’re using 1 x 3 pieces for the frame and that they are oriented flat (as opposed to on edge). Splines are not an acceptable way to handle these joints. A typical spline penetrates only about 1/4″ into a 3/4″ or 7/8″ thick board, and that isn’t enough to overcome the strains this table top is likely to encounter. I’m not sure why you’re averse to using mortise-and-tenon joints, but that is the right joint for this application. Whether it’s a bridle joint, a lap joint, a mortise-and-tenon-joint (with or without haunches) or a loose-tenon joint, you need the frame members to support each other along their entire width. The only other alternative, in my opinion, would be a miter joint, reinforced by a biscuit.

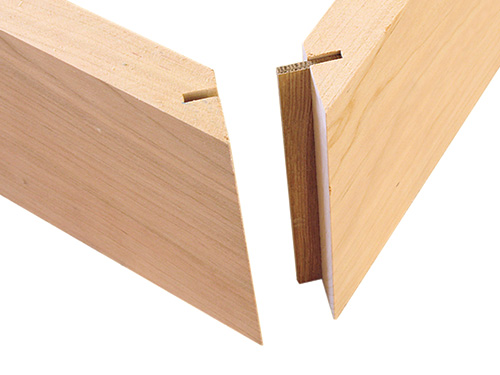

If you’ve already cut the pieces for butt joints, and you don’t want to start all over, the only satisfactory way to complete the joinery is with loose tenon joints. To make this joint, you need to make complimentary cuts in the ends of the rails and in the edges of the stiles, and then make short pieces of tenon stock to join them.

If you don’t have access to a horizontal mortising machine, you’ll have to cut the mating slots with a router and a straight bit. You didn’t mention the thickness of the frame members, so I’ll assume they’re 7/8″ thick. For 7/8″ stock you can use a 3/8″ spiral upcut router bit to make the mating mortises. For 3/4″ stock, you will have to use a 5/16″ straight bit. 1/4″ is too small, and nobody makes 5/16″ spiral bits with 1/2″ shanks for routers as far as I know.

If you plan to go further with your woodworking, now might be the time to make an adjustable router mortising jig. There are plenty of plans around for this type of jig, and Woodworker’s Journal may have one that works for you. Either way, you’ll need a plunge router, a straight bit long enough to give you a strong enough joint, and a way of controlling the cut.

“When I was in a pinch, I used to make up simple jigs to cut these two types of mortises for a particular job. The end-mortising jig (for the rails) consisted of a U-shaped plywood carrier with a template screwed to one end. The template had a 1″ wide slot in it, sized to create the mortise I wanted using a 1″ diameter. template bushing. In a 3″ wide rail, you’d want probably a 2″ long mortise, so your template slot would be sized to produce a 2″ slot with your 5/16″ or 3/8″ bit.

For the stiles, the jig was simply two pieces of wood with a similar template screwed to them. Clamp your work piece between the two pieces in a vise, and rout away. You can probably get away with 1” deep mortises for a job like this, but the outer edges of the stiles are still going to be exposed to breaking forces along their long grain every time someone props his feet on the table.