Over the years I’ve acquired several oilstones for sharpening. They do not hone very well due to the buildup of oil and grime. Is there any way to clean up these stones make them usable again, and can they be re-flattened? – Ted Holm

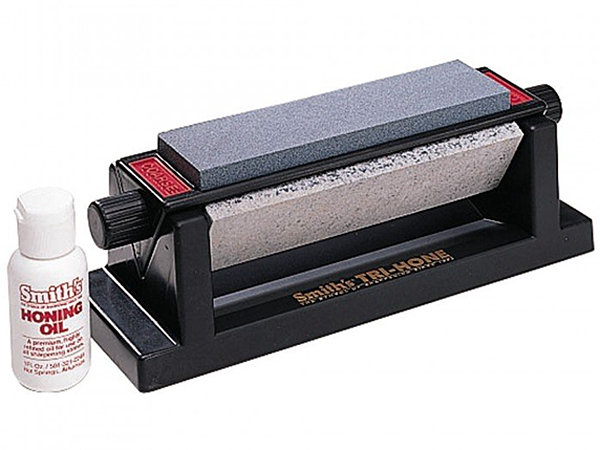

Ernie Conover: Oilstones take two forms: synthetic and natural. Natural Arkansas stones are quarried from a highly pure silica rock, called Novaculite, found only in the areas surrounding Hot Springs, Arkansas. The name Novaculite is derived from the Latin word novacula, meaning sharp knife. Arkansas stones are available in four grades: washita, soft Arkansas, hard Arkansas and black hard Arkansas. Washita is the fastest cutting and is used for reforming edges and/or angles. Soft Arkansas is a general-purpose stone, good in itself for things like pocketknives. Hard Arkansas is nearly, but not quite, a polishing stone. Black hard Arkansas is a true polishing stone and is often called surgical Arkansas.

The advantages to Arkansas stones are that they are fast-cutting and leave a superlative edge. They must be used wet and, while water will work, only oil is really satisfactory—a bonus is that it prevents rust on your tools. A disadvantage is that washita and soft Arkansas stones are prone to cupping, but, as with any stone, re-lapping is a simple matter.

Manufactured India stones are sold in coarse, medium and fine. They do a great job, but I know of no true polishing stone in the India line. Therefore, a hard and black hard are needed to augment India stones in order to establish a polish. They are much more resistant to cupping than Arkansas, but they absolutely require oil.

Oilstones will work with almost any oil. So-called honing oil is really only mineral oil available at drug stores at a much lower price. I have always favored thinning mineral oil with about 20 percent kerosene. Your oilstones may be cleaned in a solvent such as kerosene, mineral spirits or even lacquer thinner. They may also be flattened and/or renewed by placing a sheet of 60-grit wet/dry sandpaper on a wing of your table saw or on a piece of glass. Rubber cement will anchor the paper in place but allow easy removal. I use kerosene to lubricate the sandpaper during the stone-flattening process.

Ernie Conover is Woodworker’s Journal’s woodturning columnist.