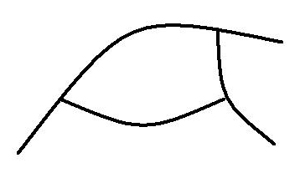

I have turned an 8” diameter ball. I would like to router arc intersecting grooves on the surface using a 3/8” ball end router bit. I want the arcs to be about 5” to 6” long and intersect at the end of an arc going off in another direction. Here’s a sketch illustrating the style of router lines that I would like to apply to the surface of the wooden ball with a router. I cannot “freehand” them, as I want the arcs nice and true as opposed to a wiggly line.

HOW CAN THIS BE DONE ACCURATELY ON THE SURFACE OF THE WOODEN BALL? – Howard Schroeder

Ernie Conover: Howard, I know of no way that this can be done in the average woodworking shop. I surmise that you may actually want the arcs to engage a follower and that they are cam faces? (i.e. this is a prototype.) If that is the kind of precision you need, then you need to take the ball to a machine shop with a multi-axis CNC machine. Even then, it may take a very sophisticated fixture. The curvature of the surface is the problem here, for you have to keep the router square to that — no small problem. If it is strictly a design, I would probably carve the design with mallet driven V gouges, as I could fair a reasonably accurate curve. Layout then becomes the biggest problem. Again, the fixture to hold the ball would be the most problematic part of this operation.

Tim Inman: I’ll make some assumptions to give you my answers. Is this a one-off project, or are you wanting to mass produce these? To cut really nice router-formed grooves or arches, you must make a template. The template must conform to the arch of the surface somehow. One way would be to cut the arches for the template on a flexible piece of material, then cut the template with relief cuts to allow it to form over the surface of a sphere. THEN, you have to figure out a “long-necked” template guide for your router — or a router pendulum jig. Obviously, cutting inside the sphere is much more difficult than cutting on the outside.

If this is not a mass produced project, here’s a better suggestion — at least from my viewpoint. Draw the arches directly on the wood, or transfer them with heat from a photocopied piece of paper. Once the wood is clearly and accurately marked out, get a really good, sharp carving chisel and mallet. Cut the grooves by hand. I know, I know… But really, there are often times when a job can be done the old-fashioned way with good tools and a little skill, and the job can be done quicker than the time it takes to set up the power tools.

If it is a mass-produced project, then you’re going to become an expert jig and fixture man — and learn the trial and success process firsthand. Send us a picture when you get this done!