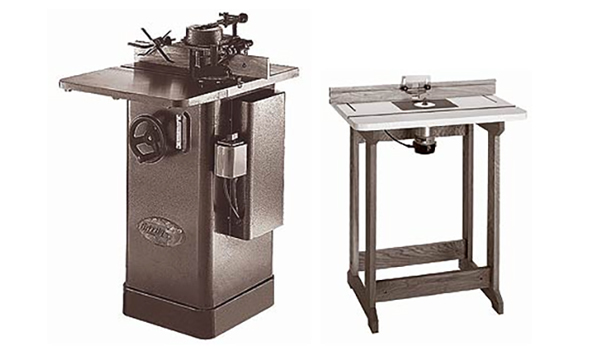

This woodworker wants to know if there is any real advantage to getting a shaper. He wonders if there are any operations on a shaper that he can’t duplicate with a good router, router table and an Incra Jig?

Michael Dresdner: You can move the same amount of dirt with a 1/2-ton pickup truck as you can with a 2-ton pickup … it will just take more trips. A shaper typically has a much larger motor and spindle. It does the same thing but can take larger cuts both in depth and height in one pass. It also requires cutters that are, by and large, much more expensive than router bits. The prevailing issue will be the same as it always is when you decide how heavy-duty a tool you need: is the speed and durability worth the money?

Rick White: The short answer is no. There’s very little a shaper can do that you can’t duplicate with a router table. Shapers are used more often in industrial woodworking shops, and I do almost all my machining of wood with a really good, well-built router table. The one thing a shaper has going for it is that it comes with a split fence, but you can build that into your router table design without much hassle.

Ian Kirby: A good quality shaper is preferable to a good quality router. The shaper is more sturdy and should have a better fence, and will likely have more power and speed and flexibility. The most important thing is that it can be easily fitted with a power feeder, which is the key to getting the best results with most molding and shaping operations.