Issue 596

Issue 596

Clamping Tricks

Gluing and clamping is one of woodworking’s bread-and-butter activities. If you prepare your stock well, dry-fit the pieces carefully and then move on to glue and clamps, assembly can be pretty mundane. But, it can also be quite stressful — it’s very hard to unglue something.

Gluing and clamping is one of woodworking’s bread-and-butter activities. If you prepare your stock well, dry-fit the pieces carefully and then move on to glue and clamps, assembly can be pretty mundane. But, it can also be quite stressful — it’s very hard to unglue something.

There are also times when assembling a project can drive you batty. Small parts or irregularly shaped stock are two examples of clamping challenges you’ll encounter sooner or later. I’ve clamped quite a few guitar bridges in place, and it always seems a wrestling match: awkward clamp placement, limited access through the sound hole, weirdly shaped wood and the demand that something be located precisely. I’ll admit it…at times I’ve expressed some bad words.

But a few pointers can sure come in handy. Our featured video today offers some tips for gluing and assembling. We also take a look behind the scenes at the development of Rockler’s popular Bandy Clamps. I hope you find these videos interesting. But I would also like to hear some of your go-to tricks for glue-ups. I’ll share what you share!

Rob Johnstone, Woodworker’s Journal

![]()

Featured Videos

Gluing, Clamping and Sanding Tips for Small Box Parts

![]()

Who Designed the Bandy Clamp?

Tricks of the Trade

Clamping

-

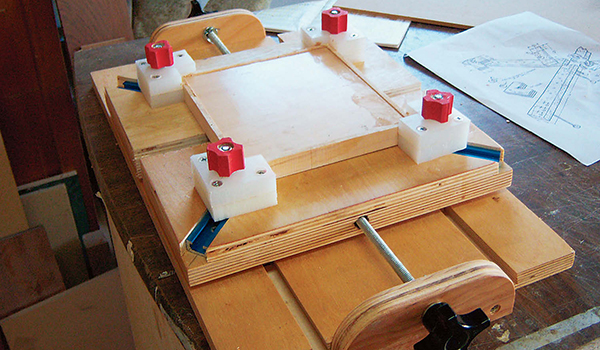

Making a Frame-Clamping Jig

Making picture frames is easy with this simple clamping jig. Fast, accurate clamping and easy glue cleanup are just two features of this practical jig.