If you appreciate the curly maple Shaker-inspired Dresser on the cover of our June print issue and wonder where the devil you can get some figured maple like that to build your own, I was asking myself a similar question back in February when we were designing the project. Time was getting short, and I needed a quality source for some handsome maple in a big-time hurry. I’m still thanking my lucky stars that C.R. Muterspaw Lumber in Xenia, Ohio, had just what I needed.

Chad Muterspaw founded his lumber business back in 1999, and he traces that love for wood all the way back to his ninth-grade shop class. Chad recalls his first school project: a sassafras dartboard cabinet that he remembers “sanding on for weeks.”

“I brought it home and Dad put it up. Wouldn’t you know it: it didn’t fit a standard-sized dartboard. We looked and looked before we finally found one to fit it, but I still blame my old shop teacher for that one,” Chad recalls with a smile.

But that little setback didn’t curb Chad’s appreciation for woodworking or teaching others about it. A fascination with woodworking stuck with him right through college at the University of Dayton, where he majored in education. He recalls that while his roommates were subscribing to sports magazines, Chad would pore over the latest woodworking publications. His buddies thought he was a little nuts, but he didn’t care.

After graduating, Chad taught physical education for a few years in the Xenia school system, but in his spare time he was still building furniture for friends and family. The “pull” of woodworking was strong enough to actually make him consider quitting teaching and pursuing the craft full-time. But an industrial technology teacher he knew advised him to consider otherwise. His suggestion: rather than change careers, just change focus — go back to school and become certified to teach industrial education. His dad also cautioned him to not be too quick about turning a passion into work. Chad took the hints and, about a year later with certificate in hand, he began teaching industrial arts at Xenia High School.

He’s been there ever since, teaching as many as six periods of woodworking and construction classes each day to high schoolers of all ages. Projects have ranged from shelves to end tables to a series of Thomas Moser-inspired pieces, all churning out of the school’s 40 x 50 ft. wood shop. Chad says that, while the school has invested in a few new machines in recent years — a Grizzly 24-in. planer and a SawStop table saw — most of the machinery is vintage Powermatic that continues to service the need. Muterspaw is proud of the fact that his chosen teaching specialty does more than just teach kids how to read a cut list or decipher fractions. “My kids learn critical thinking skills, and many times I see a lift in their self-esteem by accomplishing projects. It gets them up and moving during the school day; for a few kids that are ‘on the margins,’ industrial education is the only thing that really keeps them interested in school.”

Chad doesn’t completely remember what motivated him to consider opening a lumberyard with an already busy teaching schedule. He admits to always having wanted to own his own business. Evidently, that impulse was enough incentive for him to take out a loan from his in-laws a dozen years ago and invest in that first U-Haul trailer of lumber. “I knew nothing whatsoever about the lumber business, but I told my wife Betsy that the worst thing that could happen would be that I couldn’t sell it and would just end up with a big pile of lumber. How bad could that be for a woodworker?!” She bought that logic (incredibly, some might say), and the two invested in poplar and oak to get things started. The inventory has been increasing in variety and quantity ever since, although it’s taken a long time to become established in what Chad has learned is an incredibly competitive business.

“The hardest part about getting a lumberyard going is developing relationships with wholesalers who will take you seriously when you are small and just getting going. Many of the suppliers I tried to deal with early on wouldn’t give me a chance or didn’t want to create a new source of competition for their other long-time clientele. A few just hung up on me … they could tell right away that I was new at this, and that’s all they needed to hear.”

Chad admits that, to this day, his three main wholesalers are out-of-state, although some of those early naysayer suppliers call him now and again, trying to earn his business. While he takes those calls, he hasn’t taken them up on the offer yet. Most of his inventory of more than 13 common and figured domestic species comes from suppliers in West Virginia and Pennsylvania. He and Betsy still drive to their sources to pick up new shipments, but now they buy about 4,000 board feet at a time. And, when it comes to highly figured maple, Chad’s favorite wood among what he sells, he buys everything they have on hand.

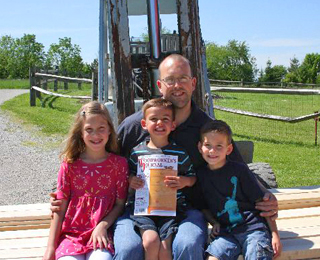

In 2004, the couple purchased their current property as a new home base for the lumberyard and to raise their three young children. Formerly, it was a house and a single outbuilding. Since that time, and thanks to the help of family and friends, the Muterspaws have added 30 x 40, 40 x 50 and 40 x 60 ft. outbuildings to the lot. At any given time, Chad estimates that his total inventory is around 20,000 to 25,000 board feet.

Muterspaw Lumber continues to operate by a decidedly small-business approach. The couple have no debt related to the business and resist the option of loaning money in order to expand it. Most of their profits go back into purchasing more lumber. In the past few years, Chad launched a website, developed by his brother-in-law and, most recently, he’s added an online store. Incidentally, that online store was what motivated me to drive down to Xenia in February. I ended up sorting through many, many stacks of prime curly maple, and Chad obliged to move skids of it around all afternoon to help me select the boards I needed for the dresser.

Other customers are clicking through Muterspaw’s website and online store, too. Chad is shocked at the amount of web traffic and calculates that “about 40 percent of my business these days is from out-of-state. It continues to grow. I have months where I sell more lumber out-of-state than here in Ohio.” The company’s figured lumber is what distant customers tend to buy most, although some will even pay to have poplar and red oak shipped to them many states away.

Currently, C.R. Muterspaw is open for business most days after 3 p.m., when the day’s teaching obligations are finished. But, that scenario could change in the next year. Chad revealed that the school system discontinued its CAD course last year; next year, traditional metalworking is on the curriculum’s chopping block, along with woodworking. Muterspaw anticipates that if his position is eliminated, he may need to resume teaching physical education at the local elementary school instead. Muterspaw says that low enrollment numbers in industrial technology courses are the reason for these program changes. “Instead of asking the question about why those numbers are low, though, the axe falls on the program; our administrators don’t always address throughly enough what’s best for the kids.”

“I joke with my customers that when the lumberyard hours change to 9 to 5, they’ll know what happened to me.” But, Chad will regret the lost time with kids who are interested in learning about woodworking. That, and his ability to help them build projects each day.

Still, he’s confident that the lumberyard will see the family through whatever happens over the next year. Betsy continues to work part-time as a school psychologist, as well as helping out with Chad’s business. Chad’s dad helps out some days as well. And that love of being around wood never gets old for the teacher-turned-lumberman, who doesn’t seem to mind the thought of spending even more hours in his backyard lumber barns. “I tell Betsy, when I retire, I’ll just spend all day every day building projects for my kids. From oldest to youngest, one at a time, I’ll just keep building them whatever they need.”

Maybe even a properly sized dartboard cabinet or two…