Back in 1966, while still a college student completing his education degree, Ken Jantz was already passionate about guns and knives. So much so, in fact, that he founded Jantz Gun Service to help pay for his tuition. A year later, he married his sweetheart Venice and began teaching woodworking in Lubbock, Texas. Then, the young couple continued their gunsmithing business to help supplement the family income.

“(My mom) began buying gunsmithing tools in quantity to receive discounts and then selling the extra tools at gun shows,” recalls Shanna Jantz Kemp, the company’s human resources and marketing director. “This was really the start of Jantz Supply.”

As the Jantzs attended more gun shows, their knife-making interest grew, and they decided to begin offering tools and supplies for that avocation. Ken also shared his gunsmithing traditions with fellow knife-makers, such as checkering, engraving and file work.

Shanna says that her father has always been a “natural” inventor as well as an educator. And, these tendencies prompted him to develop new products as well as tinker with existing ones.

“Often Dad found that products he wanted to offer knife-makers were not in existence or were of quality not up to his standard. So he began manufacturing many of the knife-making components we still offer today, including guards, pommels, file guides, rivets and more,” Shanna says.

At first, Jantz Supply was a payroll of two: just Ken and Venice. Then along came children Shanna, Kenda and Brett Jantz, who grew up in the family business. All three kids continue in the company today. The Jantzs hired their first non-family employee in 1979.

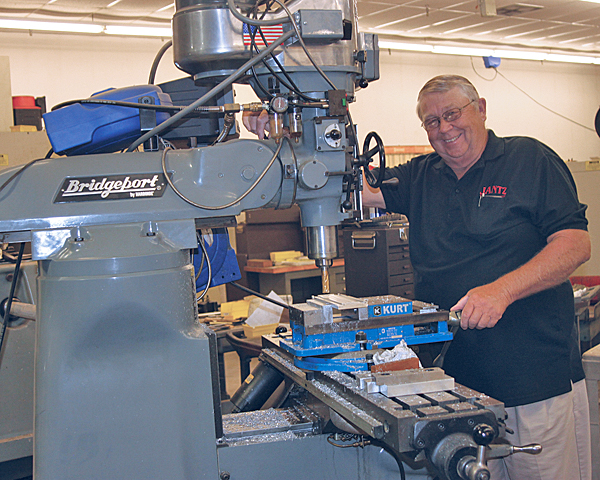

Over the years, the in-house manufacturing potential of Jantz Supply grew, too. It started with a small shop of standard grinders and equipment until 1978 when a CNC lathe was purchased to help increase output. Over time, more CNC equipment was added to the factory, plus vertical milling centers, waterjets, a laser and a wood router. The company’s original CNC lathe is still at work these days manufacturing products for the catalog.

Eventually Jantz Supply settled its headquarters in Davis, Oklahoma, and it has grown from a home-based business to a major retailer of knife-making supplies. Currently, the company occupies 50,000 square feet of warehouse, manufacturing and store. The payroll has expanded, too, with 32 employees that form its customer service team. Shanna considers them all to be part of an “extended family” with a shared passion.

“From the quality of our products, to packaging and shipping, each person who touches a customer’s order treats it like the most important order we have ever received.”

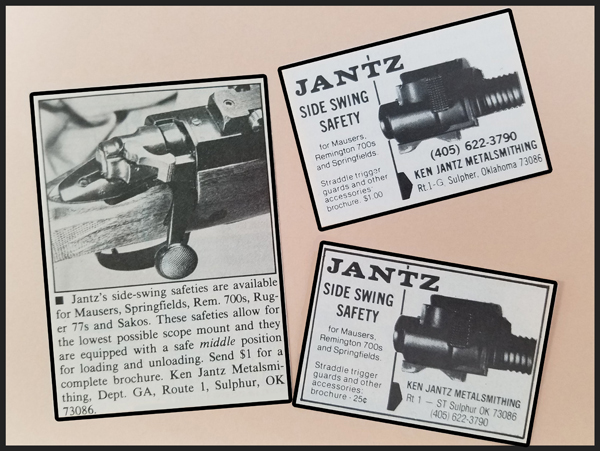

One thing has changed from Jantz Supply’s original business plan: Ken has retired from gunsmithing. But Shanna says he still receives inquiries from people who are seeking the Side Swing gun safety he developed.

But, it’s hard to imagine how he’d have time for that anymore anyway, when you consider the number of products Jantz Supply manufactures in-house — all with Ken’s oversight and approval. Shanna tallies them up: blades, guards, rivets, grinding fixtures, pommels, screws, file guides, KYDEX® presses, pre-shaped handles, spacers, mosaic pins, brass punches and many more items.

Of the company’s 6,000 individual product offerings, Jantz manufactures approximately 40 percent in its Davis facility.

What doesn’t get made there and must be sourced elsewhere undergoes the highest scrutiny before it is added to the product line, Shanna says. “All new products are tested by us in our shop using standard knife-making techniques as well as tested by professionals outside of Jantz for further quality assurance … We simply won’t accept a product for our line unless it exceeds our customer expectations for use.”

Additionally, Shanna says that Jantz is committed to providing “Made in U.S.A.” products for its customers, “because we believe in the longstanding tradition of U.S. quality and workmanship.” But what can’t come from stateside sources is selected carefully from other providers around the world.

One product group Jantz Supply has pioneered over a half century of business is its easy-to-assemble knife kits. They’re designed to be woodworking projects, mostly, and they include a pre-shaped and sharpened blade, handle material, pins or rivets and step-by-step instructions.

“All you need to complete a knife kit is epoxy, a file and sandpaper,” Shanna assures. “Of course, the more advanced tools you have, the easier it is. Most moderate (skilled) woodworkers will have more than the necessary equipment already in their shop.”

But, for those customers who want to make a truly one-of-a-kind knife, the various components can be purchased individually, too.

“Everyone can choose their own handle material from our extensive selection of exotic woods and man-made products. They also can choose their own rivets, pins or decorative screws, as well as guards, pommels and other design elements to make their project completely their own.”

While 2016 marks Jantz Supply’s 50-year milestone, Shanna says customer appreciation won’t involve “special” pricing this year. Rather, Jantz always provides its inventory at the lowest possible price and passes any manufacturer discounts directly on to customers.

“We believe that customers should be able to buy what they want when they want it and not have to wait for a sale to get the best price. I can guarantee, you are always getting our best price when you buy from us.”

Reflecting over the past half century, Shanna attributes Jantz Supply’s success to its unsurpassed dedication to customers and a commitment to providing high quality components, blades and equipment at a great value. By maintaining these company values, Jantz has enabled more people to pursue a knife-making passion than ever before.

And, what started as a family business continues in that tradition today.

“As our company moves into the second and even third generation, with grandchildren beginning to work at Jantz, we remain dedicated to our customers and the knife-making community now and in the years ahead,” Shanna says.

Learn more about Jantz Supply by clicking here.