When most of us need a sanding block, we grab a piece of scrap wood, cut it into a rectangle, slap some cork on the bottom, and call it done.

When Todd Deshler needed a sanding block, he went to design school, made an incredibly comprehensive dream list of “must have” characteristics, and set about to create the best darned sanding block in existence. The result is the Preppin’ Weapon, the result of many years of his saying “Boy, if I could design the perfect sanding block, this is what it would be.”

He certainly had enough years to think about it. An avid restorer of vintage cars, Deshler and his brother have spent the past three decades running a successful auto body shop. Along the way they developed a number of clever tools to make the work easier, fabricating them first for the shop, then selling them to others. The Preppin Weapon sanding block is one of the latest, and had its formal introduction just two years ago at the AWFS woodworking show. How he came up with this remarkable design is a story in itself.

“I’ve always been process oriented,” Todd explained. After years in business, often wondering why their hard work did not result in higher profits, he went to design school at Cornell to study efficiency and ergonomics. “I realized the key to designing an ideal product was to start with a wish list of what you want the tool to do, and how it will do it.” Take a gander at the wish list he generated for the Preppin Weapon.

He deemed it must:

- Fit a normal human hand comfortably

- Use normal American sandpaper (not expensive PSA or hook and loop)

- Relate well to both the work below it and the hand above

- Float (Those who wet sand often use a water bucket. If the block falls to the bottom, it sits in the grit; if it floats, it self rinses.)

- Have an easy-to-grip surface when wet, dry, or dusty

- Use inexpensive sandpaper efficiently without wasting a large part of the paper

- Change paper quickly and easily

- Be the right weight not too heavy or light

- Have visual clearance, with the top tilted back so you can see what is happening when the block is in tight places

- Spread the load across the hand, giving you finger tip control without creating cramp inducing pressure points.

- Have retaining clips that are easy to load, stay open and don’t require three hands when you load the sandpaper, yet stay tight enough to hold four strips of sandpaper without the need to readjust the tension when you tear off each sheet.

“I designed the shape by carving balsa wood models,” Todd told me, “and found that the window of comfort varied less than ten percent. There was essentially only one shape that worked. Too high and it feels clunky; too low and your fingers get in the way. There is only one sweet spot.”

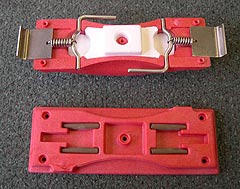

The result is impressive. All the metal parts are stainless steel, so they won’t rust or wear. The body is molded from ABS with an added structural foam so that it floats, and the weight, at about a pound, is just right. The surface is not slippery either dry or wet, and seems to get even less slippery with time and use. On the bottom, the sanding bed is lined with closed cell neoprene foam, which has just the right amount of give, but still offers a true flat surface.

The block loads four quarter sheets at once, or one full sheet cut into four strips. There are four colors available, but that is not just to look pretty or spot easily in the shop. It is designed so that you can load each color with a different grit of sandpaper and quickly grab the right grit.

“Once I had the design,” he said, “I had a model made and took it home to my wife. She flipped the lever up and it hit her in the knuckles. I went back to the drawing board and added internal dampers to prevent that.”

His first resounding success was two years ago when he took the block to the Woodworks show in Ontario. “I asked people ‘How many of you own a rubber sanding block? How many of you like your sanding block?’ Most didn’t.” He reasoned that anyone who sands for more than fifteen or twenty minutes would appreciate the Preppin’ Weapon. Unless I’m missing something, that would include almost all of us.

Admittedly, he says, men and women regard it differently. “Men walk up and ask ‘So, what’s so great about this?’ Women come up, put their hand on it, heft it, and immediately ask the price. I don’t have to explain anything. They get it right away. It just feels right to them.”

Though his products are designed for auto body shops, this one was a perfect fit for the woodworking industry, and it’s become his largest market. In addition to auto body supply shops, they sell direct online at their own website. A quick search found them offered by other online vendors, often at a discount. I’ve been told that one instructor at prestigious Palomar College has sold over a thousand by simply showing them to his students.

“I realize that most woodworkers make their own blocks out of wood,” says Todd, “but it’s hard to make a wood block with internal clips in your spare time.”

Curious, I asked Todd why do so many devoted customers feel it is worth spending up to $20 for a hand sanding block when they could make a wood block themselves. He replied simply, “You’ll understand it when you start using it.” You know; he’s right.