Great ideas sometimes come innocently enough, and from unlikely sources.

That seems true for Tim Owens who, about eight years ago, was wandering a Toledo-area shopping mall during the Christmas season. He saw a woodworker making lettered signs in a kiosk and stopped to check them out.

“The guy was doing all the lettering work by hand, and it took a long time to make each one. He told me he would take in about $25,000 during the season, and that just seemed incredible. The signs weren’t even that good!” Owens recalls.

Then the inspiration came: Why not automate the process? Tim thought that if he could equip a kiosk with a small CNC router system, it could do all the carving but much faster. A worker could just load a wooden blank into the machine, program the customer’s desired lettering and hit “Go.” If the idea worked, Tim reasoned, sign-making kiosks like this could be franchised to malls all over the country.

But, the automated kiosk theory quickly posed a big challenge. Owens couldn’t find a suitable small CNC system, other than some designed for making jewelry and costing about $18,000. So, being a resourceful engineer, he decided to build one from scratch. About a year later, working on the project in his free time, Tim finished his first prototype. But a second challenge presented itself: the yearlong “hobby” had taken a bite out of the family budget, and his wife Melissa wanted some return on that investment. So, Tim needed to start selling, and soon. He decided to sell his CNC machine on eBay. In twelve hours, it had a buyer. The next machine he parked on eBay lasted just 24 hours. “That proved to me that I needed a new model. Forget the kiosk idea! I could sell just the CNC machine,” Tim says.

And with that revelation, Next Wave Automation was born.

At first, Tim planned to only market his CNC machines through eBay, hoping to keep his day job and selling 50 or so units per year for added income. He and Melissa ran the business at home. They assembled machines in the dining room, basement and garage. Despite keeping the scope of things small, the potential for growth seemed solid.

“There was just nothing else out there at the time like what I was making. What was available in terms of small CNC routing systems wasn’t even remotely affordable or preassembled and ready to go like mine was,” Tim says.

In 2008, Owens decided to pursue national distribution for CNC Shark, so he set up presentations with Bosch,Rockler and a few others. Then, in Tim’s estimation, a “lucky accident” occurred. The day he was to present CNC Shark to Rockler at the company’s headquarters, Rockler’s Internet service was down.What was to be a presentation to just a few key decision makers turned out to be a room of 40 people. Tim delivered a convincing demonstration to Rockler that day, “and before I left the building, they signed with me.”

Rockler has been Next Wave’s exclusive distributor of CNC Shark machines in the U.S. ever since. Owens also markets his products to Canada and Australia under the CNC Shark label.

Even with Rockler’s broad reach into the marketplace, it took a while for Rockler customers to warm to CNC Shark technology. “There was lots of push back in the early days,” Tim recalls. “Woodworkers were calling CNC ‘cheating’ or that it took the fun out of woodworking. Things took about 18 months to really get going.”

Then a second good twist of fate happened, and Tim can only chalk it up to another happy accident. He planned to take CNC Shark to Atlanta’s International Woodworking Fair (IWF) in 2010. The machines were white at the time, with a melamine table. Tim decided to switch from the white color scheme to black, and replaced the melamine surface with an extruded aluminum table in Rockler’s signature blue color. “That color change was a big hit at the show,” Tim says. “I still don’t know exactly why, but customers told me it looks more professional in black.”

Next Wave Automation has long since moved out of Owens’s basement. Today, the Toledo-based company has 20 employees and operates out of a 4,000-square-foot facility. Product development, assembly, packaging and warehousing all happen there. Owens is proud to say that with the exception of a few parts that can’t be sourced stateside, and the Vectric design software that comes from the U.K., Next Wave’s products are made in the U.S. The company also develops the controller software in-house.

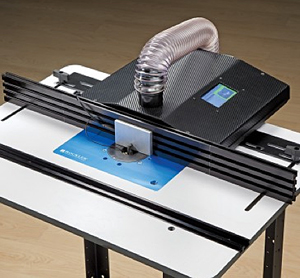

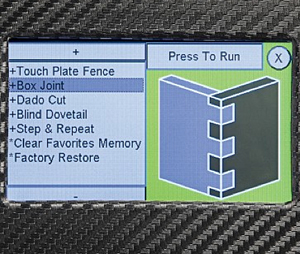

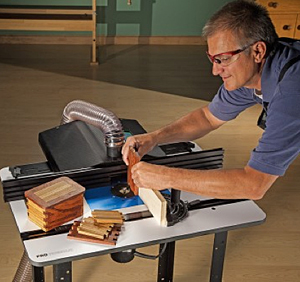

Recently, you may have seen Next Wave’s latest innovation, Ready2Rout, on Rockler’s website or in other coverage by our magazine. It’s a self-contained, automated router table fence that can cut half-blind dovetails, box joints, dadoes and fluting using a simple touchscreen and ordinary router bits. The fence positions itself for each cut, but workpieces are still fed past it in the conventional manner. Ready2Rout doesn’t require a separate computer and bolts to most standard router tables. Out of the box, it performs six different functions and can also store custom settings that are easy to program in the shop. A USB port makes it expandable for future applications.

The idea for Ready2Rout came about 18 months ago when Next Wave was considering other woodworking functions that could be automated. Tim says an automated router lift was being considered along with some other machines. But the idea for a fence that could step off joinery repeatably and with accuracy to .001-in. “really got everyone excited,” Tim recalls. “We’ve designed it to be very user-friendly. We want woodworkers to walk up and be able to figure it out. The onboard touchscreen, and not having to attach Ready2Rout to a computer, are key features.”

These days, Next Wave isn’t the only source for small-shop CNC systems anymore. Ever more woodworking machinery suppliers are jumping on the automated bandwagon, too, with new models coming to market every year. But, among the choices available to us, Owens promises that Next Wave will always make its machines backwards compatible.He sees that as a big advantage to the end user. “We’ll never leave our customers on the side of the road with their unit, in terms of expandability … we will provide an upgrade path to help users take the next step forward without having to buy a whole new CNC machine.”

For instance, Owens says the company currently is working on fourth-axis technology for CNC Shark. It will enable the machines to rout curved surfaces, such as cabriole legs or turnings, in the manner of a lathe. When fourth axis goes to market, there will be a retrofit for earlier CNC Shark machines, too.

Owens doesn’t see small-shop CNC technology as a “flash in the pan.” Its benefits are here to stay for woodworkers looking for added precision or repeatability as well as non-woodworkers hoping to merge their artistic and computer skills with wood. He speculates that the next generation of tech-savvy woodworkers might even consider CNC technology to be a necessity.

As the market for small-shop CNC grows, Tim is proud of his company’s leadership position within it. “Recently a competitor told me that, in terms of their own product development, we’re the only ones on their radar. Next Wave is the one to watch, because we’re the ones still pushing the envelope. At the end of the day, that makes me feel pretty good.”