If the alchemy involved with choosing wood finishes and the uncertainty of using them correctly prevents you from moving outside your “same-old” choices, it might feel like the only reliable options for your projects are the oil-based stains and varnishes you’ve used for years. While dependable, however, they do have downsides: oil-based products dry slowly and contain solvents that are neither healthy for you nor good for the environment. But there are safer, equally easy-to-apply, water-based options, and Brian Barry, president of Aqua Coat, would like to introduce you to several of them.

Aqua Coat was founded more than 20 years ago when, Barry says, there was an “extreme lack of choices” for DIYers and woodworkers who were searching for water-based alternatives to solvent-based wood coatings. To help fill that need in the marketplace, the company has developed water-based grain fillers, stains, blotch barriers, sealers, urethanes and lacquer that all are designed for hobbyists to use successfully.

“We want to make the transition from solvent (to water-based) easy and fun for our customers, with the added bonus of being healthier for woodworkers and their families,” Barry says.

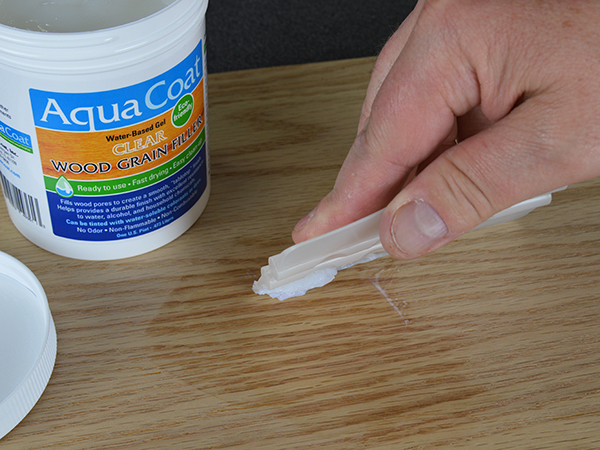

Aqua Coat’s most popular products are its gel-based grain fillers, which come ready to use out of the container in either clear or white options. If you haven’t used grain filler before, it’s intended to level the surface of open-pored woods like mahogany or ash. Barry says the usual options for grain fillers are either too fluid to be easy to control or come in putty form that must be diluted with water. The process is messy and the dried filler is hard to sand.

By contrast, the gel consistency of Aqua Coat grain filler makes it easier to apply because it has enough body not to drip while still flowing smoothly into the grain. It’s ready to use and requires no dilution, which helps to minimize waste. The water base also makes the filler dry quickly and offers quick cleanup.

“We feel Aqua Coat’s grain fillers can reintroduce woodworkers to the immense benefits of using (fillers) on their projects to create smooth, glass-like finishes, Barry says. “Many people have told us they can’t believe they have gone this long without using it and are surprised at the improvements that have been made.”

Aqua Coat manufactures 22 colors of water-based wood stains as well. They are available in pints, quarts or gallon sizes, plus concentrated tinting colors to make custom stains and transparent toners for warming up the look of any Aqua Coat topcoat. Low odor and non-flammability are two big advantages of switching to water-based stains, but they also dry much more quickly than oil-based stains.

“Our stains keep their color for longer periods of time, they provide a richer hue of color and clean up with water,” Barry adds.

One common criticism of water-based stain is its tendency to raise the wood grain during application, which then requires additional sanding. Barry says those annoying grain-raising issues can be minimized by using Aqua Coat’s water-based Blotch Barrier before applying stain. And, as its name implies, Blotch Barrier promotes a more uniform penetration of stain on porous hardwoods and softwoods, such as cherry, maple, poplar and pine.

“We also recommend our X-119 High Build Sanding Sealer,” Barry adds. “It helps you fill and seal the wood before applying your final topcoat.”

But where the “rubber must meet the road” on a wood finishing regimen is how easy-to-apply and durable the final topcoat is. Aqua Coat’s most sought-after topcoat is Aqua Thane — it’s a hybrid blend of acrylic and urethane that builds quickly and dries clear. Barry points out other attributes that woodworkers will appreciate: Aqua Thane can be applied with a synthetic brush, foam applicator or HVLP sprayer; it’s self-sealing and dries fast; and it offers low odor and soap-and-water cleanup.

“Our customers tell us they love using Aqua Thane because it looks soft and sensuous but still creates a protective hardness that is scratch- and mar-resistant and protects against moisture,” Barry says.

For even more durability, Aqua Coat offers a cross-linker that can be mixed into Aqua Thane before application to increase its cured hardness and resistance to chemicals and heat.

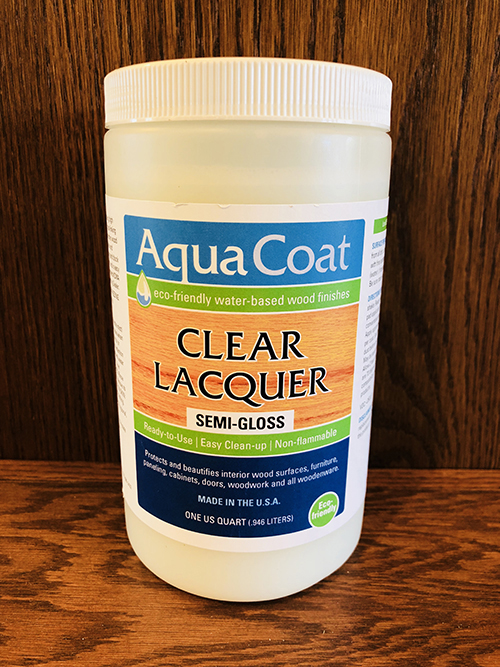

And, if you’re a fan of solvent-based lacquer for its ability to level well, cure hard and dry fast, Barry says Aqua Coat’s acrylic Clear Lacquer is a water-based alternative that just might meet or beat the lacquer you currently use. Its non-yellowing chemistry contains coalescing, leveling and de-foaming agents that make it a fully formulated waterborne product. Even better, Aqua Coat Clear Lacquer is an industrial quality top coat that’s DIY friendly: it can be applied with an HVLP system, synthetic brush or foam applicator.

“We usually recommend this product if your project is likely to see a lot of wear and tear, like an entryway bench or a step stool,” Barry explains. “It provides excellent scratch and mar resistance and, just like all other Aqua Coat products, it is ready to use out of the container.”

The lacquer is available in gloss, semi-gloss, satin, low sheen and “rubbed effect.” You can buy it in quart, gallon and five-gallon sizes.

Barry points out that Aqua Coat’s broad product line is keeping step with the industry’s increasing demand for safer, low-VOC water-based finishes. In fact, over 50 percent of all finishes sold in the U.S. these days are waterborne, and that statistic is increasing by one to two percent per year.

The company is fully committed to helping small-shop woodworkers make the switch from solvent- to water-based finishing options by creating quality products and providing the necessary information for hobbyists to use them correctly, Barry says. Aqua Coat also honors its ecological commitment through the use of recyclable packaging. He feels the company’s bigger environmental impact, however, will be on the industrial side of the business, where Aqua Coat is helping to remove chemically laden products from the finishing process.

“Our continued mission to provide environmentally friendly as well as healthier alternatives to woodworkers and their families has been a passion for us since the beginning,” Barry says, “and it will continue to be our mission going forward.”

Learn more about Aqua Coat products by clicking here.