In the cordless power tool industry, making the longest running, highest powered and most compact tools is a fiercely competitive business. Some companies come out of the gate as fast as possible with new technology in order to grab the “first-to-market” brass ring. But Bosch’s Jason Feldner, group product manager for cordless and benchtop power tools, feels that, now and again, timing is more important than being first in line.

That’s why, if you’re shopping for a new Lithium-ion drill or impact driver with a brushless motor in it, you won’t find that familiar Bosch blue among the latest tool colors featuring this cutting-edge motor technology … at least, not yet.

“Making a cordless tool that really takes the next big step in efficiency is a more complex undertaking than just putting a brushless motor into it,” Feldner says.

But let’s step back a moment. Maybe you’re not familiar with what all the buzz is about regarding brushless motors these days or even with what makes them so special in the first place. I’ll admit that I wasn’t either, until a recent Bosch media event brought the technology into clearer focus for me.

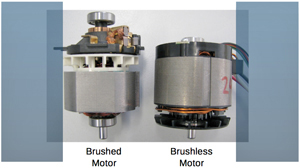

As you may already know, in a conventional electric tool motor, a pair of little carbon blocks rub against a commutator on the motor shaft in order to carry electricity from the tool battery to a series of electromagnets. Electricity turns those magnets on and off and reverses their polarity. It allows them to both attract and repel a ring of conventional fixed magnets that surround the motor shaft so it will spin. Those carbon “bridges” produce friction as they rub the commutator, and even a seemingly tiny bit of friction reduces motor efficiency.

“In a battery-powered tool, where power delivery is finite and longer battery run time is so important, anything that decreases efficiency is a big deal to us,” Feldner admits.

The way to get around the need for motor brushes is to switch the positions of the electromagnets and the conventional magnets. In a brushless motor, the electromagnets form the outer “fixed” ring and the conventional magnets are mounted to the shaft instead. In this configuration, there’s no need for a brush/commutator bridge to deliver electricity. The electromagnets don’t have to move, so they can be wired directly to computer circuitry that controls them. That explains the industry abbreviation “E.C.,” which stands for electronically commutated. This alternative motor design, Feldner says, adds about 30 to 40 percent more efficiency over comparable Bosch tools with conventional motors. Losing the brushes and commutator also makes the motor smaller, so the tool housing can be more compact.

And these are the reasons why E.C. motors are being hotly pursued by most makers of professional-grade power tools these days. Efficiency, which translates to longer battery run times and more power, will help the industry take that next big step with cordless tools.

“Brushless motors have actually been around for a long time, but just not implemented in our corner of the tool world. You can find them in ceiling fans, model helicopters and airplanes and even in high-end professional hair dryers. They work well in situations where a motor has to run at a consistent speed for a long time or where weight is crucial and batteries are small.”

The introduction of sophisticated Lithium-ion batteries a number of years ago meant that tool electronics had to improve as well. Tool batteries are “smarter” than they’ve ever been. Once better computer circuitry was in place, it created a platform of potential for controlling the electromagnets, too. In a manner of speaking, then, Lithium-ion has ushered in the possibility of cordless tools with brushless motors.

But, while some other manufacturers have been rolling out a variety of tools lately that contain E.C. motors, Bosch has just two — both cordless rotary hammers, one launched four years ago and another in 2010. Does that put Bosch “behind the times” with its competition, in terms of E.C. research and development?

Feldner says the answer to that question, unequivocally, is no.

He says that Bosch has been experimenting with E.C. technology for a long time, but it has continued to develop its DC brush-style motors so they “nearly match” the efficiency of some competitors’ new E.C. tools. Bosch has also continued to refine battery technology and tool electronics.

“At Bosch, we look at E.C. tools in terms of three important factors: battery technology, sophisticated electronics that protect the tool during peak use and an efficient brushless motor. You’ve got to have all three aspects working together. It’s not just about the motor. The phenomenal jump in performance is what will happen when all three of these factors are designed together, and that’s what we are going to achieve with our new E.C. tools.”

While he wouldn’t provide specifics about what’s next on the horizon for new Bosch brushless motor tools, Jason says Bosch plans to launch more E.C. tools in 2013, and he says there are tools in the mix that will be of interest to woodworkers. As you might expect with any new technology, they’ll be more expensive than comparable tools with brush-style motors. But, over time and as the E.C. tool market grows, he anticipates that prices will eventually come down on these now premium-priced tools.

Will brushless motors eventually be the norm for all cordless tools? Probably not, according to Feldner, “because there will always be price-sensitive tools on the market. I’m sure there will be a lot more brushless options, but at least at Bosch, we will apply E.C. technology where it is best suited for end users.”

In the meantime, is E.C. worth the extra cost, or does it still make sense to invest in a new conventional motor tool? Feldner says that depends on your needs. “If your livelihood relies on a tool that you use all day, every day, where performance and battery run times are crucial, that’s where E.C. is really going to benefit you in the future. And Bosch is going to be there with a platform of tools to help you get the job done.”