Not long ago I found myself in the cavernous spray room of a local refinishing company doing a comparison test of eight different upper-end HVLP (High Volume, Low Pressure) spray systems, most costing close to a thousand dollars each. Among them was a cleverly designed compact unit that looked quite out of place amidst its larger and costlier brethren.

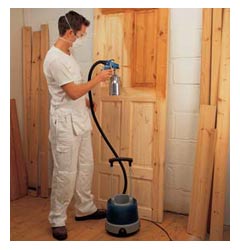

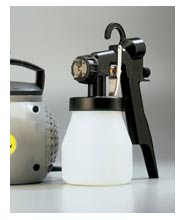

Made by Earlex, the HV5000 is a small, self-contained unit that has a carrying handle on top, a built-in well where the cup sits, a recess to coil the air hose when not in use and another recess to wrap up the power cord. Brightly colored, convenient, and downright friendly looking, it weighs in at less than five pounds and costs only $270.

It soon became the darling of the testing panel, and much to our astonishment, performed superbly in spray tests. Above and beyond its design appeal, it produced excellent atomization and a very respectable volume for such an inexpensive unit. How did it do it? One major difference was that while other units sprayed a large fan, typically close to two feet wide, this one put all its limited power into only a small six inch fan width. You may need more passes on large panels, but the spray quality was definitely there. I was intrigued by this mighty mite made in England, so I called Ian Mullaney, vice president of sales and marketing for Earlex, to find out more.

“Earlex started in 1987 by selling the world’s first DIY steam wallpaper remover,” Ian told me, “and eventually expanded into other ‘Do-It-Yourself’ products including steam cleaners in 1992, auto feed paint rollers in 1995, heat guns in 1998 and electric sprayers and HVLP units in 2000. The company founders had already been in the power tool business and used to rent out wallpaper strippers. That got them to thinking that there might be a demand for a cost-effective unit for people to buy.

“In 1992, Earlex started selling wallpaper removers in the U.S., but under the aegis of Wagner and with a different name. The unit was called the Wagner Power Steamer, and was sold until the end of 2004, at which point Earlex established a distributorship in North Carolina. At first, we sold only steam cleaners and floor cleaners because our relationship with Wagner precluded our selling decorating power tools like sprayers and power rollers, but within a year that all changed.

“Today, Earlex is a $45 million company with some 250 employees. The vast majority of our products are actually made by Earlex in three manufacturing plants in Guildford, England. We run very lean, JIT (Just In Time) manufacturing systems, which makes us able to compete in price with Asian goods.

“The reasons for our competitive pricing and quality start at the top,” Ian explained. “Julian Baseley, our current owner and also one of the founders, has a very refreshing philosophy. He does not like being ripped off, and believes in value for money. Consequently, he offers the same to his customers. We’re not here to make a quick buck. Instead of asking what is the maximum we could charge, we tend to ask what is the best price we can give to the customer.

“Earlex sells worldwide, but here in the U.S. we sell steam wallpaper removers, steam cleaners, floor and carpet cleaners, heat guns and power paint rollers in addition to HVLP sprayers. We also make electric spray guns, called ‘buzz guns’ in the industry. We sell them elsewhere but not here,” admitted Ian. “That’s largely because we feel our HVLP guns are much better. Buzz guns are noisy, heavy, produce a poor finish and create a lot of overspray. When I did my market research, I could not find anyone who had a really good experience with them. On the other hand, the average user vastly preferred HVLP guns.

“The key was merely to get the HVLP down to the right price point with the right features and let customers know it exists,” explained Ian. “For $270, we provide a well engineered, two-stage HVLP unit that is easy to use with an easy to clean gun that gives excellent atomization. We offer interchangeable metal instead of plastic needles, and deliver a higher airflow and atomization pressure than the competition. There are also lower price point rigs for people who want to get into spraying for the first time, starting with an HVLP unit that costs only $90. We can do it because we make 400,000 HVLP units per year in England, so we get the benefits of economies of scale that come with that level of manufacturing. It is all just an extension of our company philosophy.

“We have an R&D department in the UK with about a dozen people who do nothing but design, develop and improve products. The engineers all want lots of airflow, but the designers all say make it compact. Our units are a happy marriage of those two demands. We try to think about who the user is and what he or she really wants. Things like having storage for the hose built right into the unit and a place to put the gun down are important to make our products work better. We always try to put our customer’s hat on. When you open up one of our boxes, instead of seeing instructions, you first see phone numbers to call if you need any help. Customer service is at the top of our list.”

I pointed out that most of our readers have not heard of Earlex before, and asked Ian why that is. “We really did not officially launch our HVLP units until May of last year,” he replied, “so in that respect, we are a relatively new spray gun company in the U.S. Currently we have only a couple of hundred dealers, but hope to have three or four thousand soon, including paint stores, hardware stores and woodworking specialty stores. Ultimately, our aim is to be the largest HVLP provider in the U.S. market.”

Being a relative unknown can be a bit of a challenge, even for so large a company. “Getting people to make a leap of faith into a company they have never heard of can be difficult,” admitted Ian, “but the truth is that we are the largest manufacturer of HVLP systems in the world. I am just hoping that those people who want to get into HVLP and want to find one they can afford will be delighted with the results we can give them.”

I doubt that will be much of a problem. After spending an entire day watching my team test nine fairly high priced HVLP units, the foreman of the finishing shop we borrowed for the test sidled over and asked if I would lend him the Earlex unit for a while. He uses an inexpensive portable unit for spraying installations on-site, but he liked the Earlex better.

Frankly, I can’t think of a more flattering commentary.