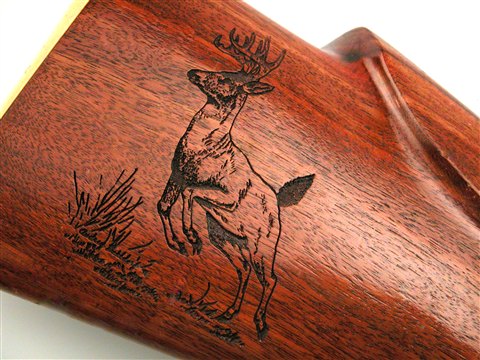

“There are just some things only a laser will do,” explained Mike Dean when I asked him why a small shop or hobby woodworker would need a laser. “It’s the perfect tool for massively expanding your woodworking options. You can customize in ways you could only dream about before, and it is as easy as printing to a computer printer. If you can print, you can laser. It’s unbelievably easy to use.”

Mike, along with his two partners, Steve Garnier and John Doran, owns Epilog Laser, a company taking firm aim at the woodworking market. Although large shops and specialized manufacturers have been using lasers to cut wood for some time, Epilog is working to put that technology within our grasp.

The Zing, a model which came out earlier this year, is a compact, relatively inexpensive but fully featured unit aimed at first-time laser owners, making it perfect for small businesses and high-end hobby woodworkers. “We sell to a lot of hobby woodworkers,” Mike told me. “We’d like to see them in more shops, and for that reason, we go to most of the woodworking shows. You’ve probably seen us there.

“While the Zing is a great entry-level laser, our most popular laser is our Helix model. It has a 24- by 18-inch work area, a 45-watt laser, and costs about $19,000. The laser tubes themselves change technology as they go into higher wattage. That change occurs at about the 50-watt level, where they get significantly more expensive, so a 45-watt gives you the biggest bang for the buck. Our second most popular is the Helix with 75 watts, because on your second machine, you always buy as much power as you can afford.”

The company was incorporated in 1988 by Mike’s partners, Steve and John, both electrical engineers from Georgia Tech. John built a laser in his basement while in his 20s, just to see if he could do it. Steve worked at Melco Industries doing motion control, so they decided to pool their talents to make a laser that moved around. When Steve found himself downsized while they were working on their second generation laser, they decided to create their own company. They felt that as two engineers, they needed a business partner, so Mike Dean became the third owner. They came up with the name Epilog, and the company was born.

“Today, Epilog has some 70 employees,” Mike told me, “as well as independent distributors throughout the world in about 50 countries. Situated in the foothills of the Rocky Mountains in Golden, Colorado, we occupy a 35,000 square foot facility designed specifically for what we do. All our lasers are made right here in the U.S.

“We manufacture two types of laser systems. Our fiber laser, so-called because the laser is developed in an optical fiber, is used almost exclusively for metal and plastic marking. All the rest of our products are CO2 lasers, and they encompass about 94 percent of our product output. These are ideal for wood. They range in price from $8,000 to $50,000 with prices based primarily on work area and laser wattage.

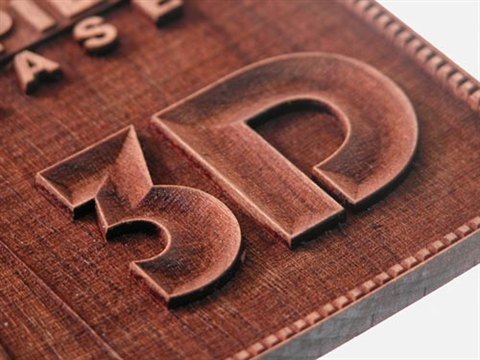

“At the bottom end, the Zing has a 16- by 12-inch table and a 25-watt laser. At the upper end is a 36- by 24-inch table with 120-watt laser. Laser wattage, as far as wood is concerned, translates only into speed. The higher the wattage, the faster the cut, but any machine will do any job. The smaller ones simply take longer.

“The laser beam is invisible, so watching it cut is fascinating. You can see where it contacts the material, but not the beam itself. Because the beam can both burn you and damage your eyes, we always keep it in an enclosed cabinet for safety reasons.

“Each machine works in two distinctly different modes, both similar to two primary types of computer printers. The plotter mode follows vector lines, and is best for cutting all the way through wood. The raster mode produces one line at a time, like most desktop inkjet printers, and is best for thicker, shallower lines, like engraving text or surface graphics. You set all the laser parameters the same way you set up paper orientation and print quality. Instead of a printer depositing ink on paper, the laser burns away a spot of wood. You can run raster, vector or a combination of the two in one job.

“Virtually any Windows-based program will translate into either raster or vector, so you not limited in either text or drawing programs. Epilog works with Corel, Illustrator, PageMaker, AutoCAD, Word, Excel, and any other Windows-based program. You set up your artwork and print. All of our machines hook up with a standard USB or ethernet connection directly to your computer. You can do your work on your laptop, take it out to the shop, and plug into the Epilog. It is really that easy.”

When I asked about the wide price disparity in the field of lasers, Mike had some interesting insights to offer. “There are several companies that manufacture similar systems here in the U.S, in Europe and in Asia. One of the technologies imported from China is a glass tube laser. While they are similar, their capabilities are limited, and the tubes don’t hold up nearly as long as the metal tubes we use. Glass tubes are throwaway and only last for a few months, while our metal tubes last for five years or more, at which point they merely need to be recharged to keep working. The image quality is also significantly poorer with glass tubes.

“Just because the box looks the same,” Mike admonished, “does not mean the guts are the same. We suggest that people look at both systems, which is why we do trade shows and make sure our distributors are available with demo equipment. If a company does not let you watch their machine work before you buy, be suspicious.”

The good news for us is that, according to Mike, Epilog plans to expand in both directions. “We want to grow our CO2 line with larger and more powerful machines on one end, and less expensive ones on the other.”

You know, I think I could make room in my shop for a laser before Father’s Day rolls around. Perhaps it’s time to start dropping hints.