For a company that started less than a decade ago with one product, a peel and stick screw cover, FastCap is certainly a growth enigma. In the short time since Paul Akers created this company, his product list has grown exponentially into an eclectic mix of astonishingly clever, yet seemingly unrelated, products. All they have in common is that they make woodworking go faster and easier, and make us mutter “why didn’t I think of that?” Still, you have to wonder how one person came up with so many slick inventions in so many venues in such a short time.

The answer is simple. He didn’t. Instead, Akers has done something far better. He’s fashioned his company to be a supportive conduit for all the frustrated inventors working as cabinetmakers.

There’s a legion of woodworkers who have come up with clever ideas for products, but who can’t get anyone to listen. Paul listens and, if the idea is good, he manufactures it, sells it, and pays the inventor a fair royalty. It’s the ultimate win-win situation, helping the inventor, the company, and even those of us who are loyal users of the rapidly growing inventory of FastCap timesavers.

“Our products are different,” Paul said, “because they are not designed by designers, but by users. The best ideas come from the shop floor. Our items come from the people who do the work. I let cabinetmakers call me personally on my cell phone to tell me their ideas. If they are good, we make them. If not, I tell them to try again and call back when they have something else.” That’s a pretty unusual business model, and Paul’s path to creating it started soon after high school.

“I built a guitar while still in high school,” Paul recounted, “then, at age 17, went to work for Taylor Guitars as a luthier, or guitarmaker. The owner, Bob Taylor, was probably one of the most influential people in my life. After two years, I went back to school and got a degree in education, paying my way through college by working as a cabinetmaker restoring Greene and Greene homes in Pasadena. I taught woodshop in high school for two years, then started my own high-end cabinet and construction company in San Diego.” Later, he moved to Bellingham to enjoy the more bucolic environs of western Washington.

“I was in my shop, exhausted, at eight one night,” Paul continued. “I had a huge white melamine job to deliver in the morning, and was facing a sea of screw holes to hide with press-in screw caps, all the while wondering why someone hadn’t invented a peel and stick cap. I sprayed contact cement on the back of some edge banding, cut it into disks, and FastCap was born. My wife was usually skeptical about such things, but this time, even she agreed that it was a great idea.”

“The next day, I turned over the day-to-day activities of the shop to my crew, and spent the next two months perfecting this new product. I took it to AWFS [Association of Woodworking and Furnishings Suppliers] in 1997, as green as I could be, and was fortunate to be allowed into the Mepla booth. I stood there and handed out a cheesy brochure to their customers. The irony is that Mepla is a very polished and sophisticated company. I did that for four days, and ended up with half a million in sales in the first year, all from that one product.”

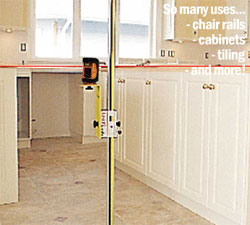

“The second product I invented was the Laser Jamb, a laser level, and the first company I showed it to stole the idea and had it on the market in six weeks.” He was so offended that he decided to protect others from what happened to him. “As FastCap grew, I got some recognition telling of how it began. People started coming up to me to tell me they heard my story, and that they had an idea, too. I knew there were lots of others who did not have a venue for their inventions, so I created a company to give them one. We pay a royalty to people who bring new, marketable ideas to us, patented or not. As a result, our company is growing at 50 percent per year based on validating the creativity of other people, both our own employees and those on the outside.”

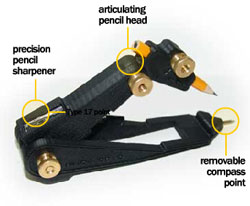

Paul is no slouch on his own — eight of the items in the catalog are his — but the rest are from other cabinetmakers. Over a dozen inventors are represented, with 20 new products in the works and many more in the pipeline. Popular items include FastCap, Accuscribe, Third Hand, Powerhead screws, a proprietary cyanoacrylate glue formula called 2P-10, and a host of tape measures in every imaginable configuration, including their popular Storypole, which lets you mark dimensions directly on it instead of reading and remembering numbers.

With so many intentional inventions, there are bound to be fortunate accidents; their popular Flatback tape measure is one such example. “I asked our factory in China to make a peel and stick tape measure,” Paul recounted, “by taking the curve out of the blade, adding an adhesive back, and eliminating the case. Because of a translation error, it came in a case, just like a regular tape measure. At first, I was furious with them for the mistake, but when I saw it, I realized how practical it was.” The tape lies flat on wood for accurate marking and wraps around curves without distortion.

About half the products are made by some 50 employees in his factory in Bellingham, which itself is run by a rather unusual set of parameters. “Two years into the company,” Paul explained,, “we were having internal inventory management issues. I called the Washington State Business Association and asked them for help. Their guy walked into the shop and said, ‘Your problem is not with inventory. You don’t know how to manufacture.’ I was shocked.

“I thought I was on the cutting edge of technology. The week before, we had gotten our first small business loan for a quarter of a million dollars because the bank president was so impressed with our factory. ‘I’d loan you any amount you want,’ he told me ‘because I have never seen a facility so well run.’ Nevertheless, we hired a Japanese consulting company. They came in and dismantled the plant, put it all back together differently, and increased our profits by 200 percent. Thank God I did not think I knew it all.”

These days, he regularly sends groups of employees to the Toyota plant to learn from them. “They are an unbelievable company. Toyota believes that everyone’s goal is to do something great for society. That’s why they allow us into their plant and donate their time to teach us kaizen.” The term kaizen refers to a collection of lean manufacturing methods including continuous improvement, just-in-time inventory, and other manufacturing and business strategies. “We’ve even moved to a stand-up office for greater efficiency,” Paul explained “and are now moving toward a paperless office as well.”

Manufacturing prowess notwithstanding, the real strength of FastCap comes from an appreciation of the people his company serves, both inventors and customers. “Our goal is to uncover the potential of people,” Paul told me. “There is greatness in every human being. People need to realize that, never sell themselves short, and never give up until they find it.”