Every so often, Journal readers write in to tell us about ideas they have for new woodworking products. We also receive reader shop tricks for clever problem solvers that make interesting and potentially even salable products. It’s clear that woodworkers and do-it-yourselfers (most of us wear both of those hats) are generally a clever and resourceful bunch. Still, not every widget we dream up is destined to be tomorrow’s great new shop gizmo with a SKU number and a catalog price.

Have you ever wondered what it takes to turn a smart idea into a tangible product? Recently, I had a chance to ask Mark Bergman, president and CEO of Chanhassen, Minnesota-based Bercom International and the inventor of line of unique painting accessories, that very question. Mark could certainly answer it from experience: his company was founded a little over a decade ago on a product that began as a coffee can and a roll of duct tape. Today, his HANDy Paint Pail and other products are sold in some 15,000 to 20,000 store fronts nationwide.

“Here’s the short answer to the question,” Mark says. “You need to see a void in the market for a product that meets a need. Then people have to understand your invention and be willing to pay for it.”

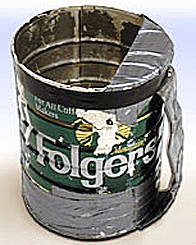

Bergman’s HANDy Paint Pail was certainly born of need back in 2000, while he was remodeling part of his basement into a bedroom. During the painting stage, Mark got tired of holding a coffee can full of paint. He grabbed a roll of duct tape and fashioned a strap for the can that fit over his hand. It was more comfortable to keep painting without gripping the rim. Then, he added a strip of tape across the top of the can for scraping excess paint off the brush. That made it even better. He used it for a few more days, and so did his wife and son. Everyone liked the convenience of it, and that’s when the green light came on. Maybe he was onto something bigger.

But Mark was no stranger to new product development at the time. A few of his previous hunches had already turned into successful products. He knew the ropes.

“In ’86, a buddy of mine and I started a company called Harber Incorporated. We had business degrees and had been working in the financial industry when I had this idea to make children’s products. That inspiration came while feeding my young kids, where I would say what lots of parents do: ‘Open the hanger; here comes the airplane!’ It occurred to me that maybe spoons shaped like airplanes, race cars and trains could make meals even more fun, so that’s what we set out to make.”

The idea worked, even though Bergman admits the two business partners knew next to nothing about making products. It was a “trial by fire” experience for these entrepreneurs, in many respects. One learning curve to overcome was the patenting process. Finding a patent attorney proved to be essential. Then came the challenges of product design which, the two realized, was beyond their wheelhouse of skills.

“You can come up with a great product concept, but it takes the expertise of good industrial designers to help you make a product efficiently and affordably. I was lucky enough to find a couple of excellent designers, Matt Leyden and Jeff Waffensmith, at an agency called Psoup here in St. Paul. They love to help inventors with new product ideas, and I’ve been working with them ever since.”

Through the process of making plastic utensils for kids, Mark learned the ins and outs of injection molding as well as the cost-effectiveness of subcontracting that work out to companies that specialize in it. He says that “Even now, we ship our products, but we don’t do any of our own injection molding or other manufacturing. All of that work is done by five Minnesota- and Wisconsin-based companies. It’s a good lean business model for us.”

Mark says says that one of the first steps of exploring any new product concept is a careful patent search. He admits to never getting too excited until he’s sure that developing something new won’t infringe on other patents. He recommends the United States Patent and Trademark Office’s website (USPTO.gov) as an excellent and free resource for exploring existing patents before contacting a patent attorney. In the case of HANDy Paint Pail, “not only had no other company ever done anything like it, but we couldn’t even find evidence of a patent for a vessel with an adjustable strap attached to it. That was an excellent sign to move our product idea forward.”

The quart-capacity HANDy Paint Pail, which has an adjustable strap, a scraper lip and a built-in magnet for brush storage, has several patents pending. “You need that level of protection for any product, and you have to extend the patenting process as long as possible to keep other competitors from creating something similar to it.”

It took Bergman and his start-up company less than two years to transform that coffee can prototype into a marketable product, which launched in January 2002. By March of the same year, Menards® was selling HANDy Paint Pail in all of its stores. “It took a couple more years to establish vendor relationships with Lowe’s® and Home Depot® before they would carry our product, but persistence paid off. We are also carried in Sherwin-Williams® and other specialty paint stores as well as most independent hardware store chains.”

Bercom International, under Bergman’s leadership, has invented a variety of other painting-related convenience products in the years since, including the HANDy Ladder Pail, Paint Tray and Paint Cup. Removable, disposable liners and re-usable lids make the paint-holding products even more versatile. The company also recently launched HANDy Bucket Builder. It converts five-gallon buckets and 2x4s into knockdown sawhorses, benches and work tables.

Mark credits the company’s “crossover” product line as one reason for its success. “Both hobbyists and professional painters use our products. It took a while to convince the pros that they could use our accessories to paint in a different, more effective way, but eventually they realized the benefits. These days, our customer base is probably 60 percent DIY and 40 percent contractor.”

While Mark admits that he’s always had an inventive spirit and a drive to “do things better,” he leavens enthusiasm with a sensible approach to business. Experience always evaluates inspiration. Even so, some products are hits, and others are misses, Bergman revealed, and that’s the challenge of developing products both pros and DIYers will understand and be willing to buy. But Bercom is committed not to be another “me too” supply company. “I know that we’re helping to improve people’s projects with novel products, and at the end of the day, that’s a darn good thing.”