“Let’s make a milling machine for wood. You and I will manufacture it and start a little business,” recalls John McConegly, about how his father-in-law — John Ducate Sr. — propositioned him to start JDS Company, back in the mid 1980s.

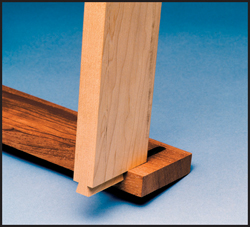

McConegly, JDS’s president, says his father-in-law always liked woodworking in the off hours when he wasn’t managing a large furnace manufacturing company in Columbia, South Carolina. But Ducate was frustrated with mortise-and-tenon joints and the mortising jigs of the time. They didn’t satisfy his machinist’s sensibilities. He thought he could build a better solution … and he definitely wanted McConegly on board with the venture.

For years prior, McConegly who was a school teacher and football coach, resisted Ducate’s offers to come work for the family business. But the lure of a new opportunity — and a new way to make joinery — finally enticed him to change his career plans.

“My father-in-law and one of his factory engineers, a really brilliant guy, made our first three-axis mortising machine with a bunch of bolt-together parts. They took that Multi-Router prototype to a woodworking trade show to see if it would get any interest from the crowd. John told me one or two orders wouldn’t do it, but five or six would mean they were on to something. They came back with 12 orders.”

So Ducate cleared a corner of his factory, pulled together a small group of his employees and set them to work making Multi-Routers part-time. John moved his family to Columbia, “and before I knew it I was assembling Multi-Routers, too. And taking them to trade shows most every weekend of the year to look for dealers and sell the machines. I wasn’t a woodworker, but I knew every nut, bolt and screw on that machine by heart. Being part of the assembly line really helped!”

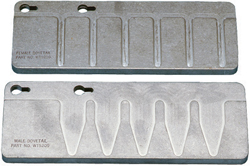

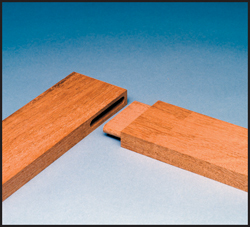

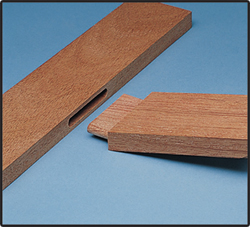

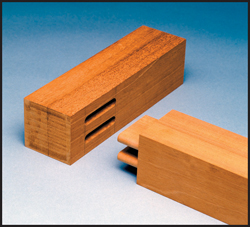

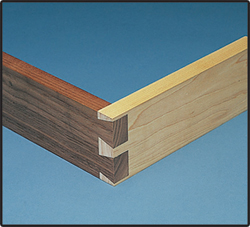

John spent about four years working the trade show circuit to develop a dealer network. In the meantime, JDS patented the Multi-Router’s design. It uses a ball-bearing follower to trace any of 26 different aluminum templates that cut mortises, tenons, box joints or dovetails of various sizes and configurations. An ordinary router, bolted to the machine, mills the wood with a spiral end mill bit or router bit in the exact same cutting pattern the follower traces on the template.

The fledgling JDS Company contracted with a small local foundry to make the aluminum castings that form a Multi-Router’s base and tilting table. Some finishing work on the castings was initially done in-house at Ducate’s factory, but eventually that work was outsourced to a local machine shop, as was the powder-coat painting process. All of the other machine parts came from U.S. manufacturers and still do today. In fact, JDS continues to contract with the original foundry that manufactures the rough castings in batches of 25 Multi-Routers at a time. The machines are assembled, adjusted for accuracy, packaged and shipped from JDS.

“We’re committed to American manufacturing for our Multi-Routers,” John asserts.

McConegly says Ducate, who really founded JDS Company, tried not to be a hands-on leader, but he made sure that McConegly kept things running smoothly. He told me, “I’ll get this business started with you, and if you can make something of it, it’s yours from there.”

That was 25 years ago now, and about 3,000 Multi-Routers later. When asked what makes the JDS Multi-Router a tool that continues to build a loyal following, McConegly recalls another early comment from Ducate that sums it up: “John, we’ve got a belt AND suspenders product here.” The reasoning: essentially, the Multi-Router is constructed to last a lifetime. “We use hardened-steel bearings and hardened-steel rods that control movement along the three axes. Our joinery templates are thick aluminum, heat treated after machining to eliminate warping. Even the follower that tracks the templates is a bearing that rolls rather than rubs against the template contact surfaces. There’s just nothing to wear out on it besides the cutting bits.”

In addition to quality components, McConegly also credits the tool’s “phenomenal” original design to its longevity. In more than two decades, JDS has only modified it slightly once to improve the micro-adjustment. It is otherwise unchanged from 1987.

But the Multi-Router isn’t for every budget; the machine without extras costs about $2,700. Templates are sold separately for around $50 each. John wants end users to get the templates that suit their needs and not those they’ll never really use, so the company doesn’t offer package deals of machine and templates together.

Because the Multi-Router’s pricing put it out of range for many woodworkers, McConegly and Ducate thought it prudent to expand the product line in the late ’80’s with another quality tool that could be more budget-accessible. This time, the two set out to reinvent table saw miter gauges which, at the time, were generally inaccurate and cheaply made. “Our Accu-Miter Miter Gauge, which uses a spring-loaded shot pin to lock in key detent angles, was the very first precision miter gauge on the market.” It gained quick acclaim with woodworkers and helped to solidify JDS as a quality woodworking tool manufacturer.

Then, in the mid 1990’s, JDS launched a new family of air filtration and dust collection products. The first SKU, an ambient air filter, was a logical choice, because Ducate’s furnace company could manufacture them easily. “There were some other ambient air filtration systems at the time, but ours was the first available to retailers,” McConegly recalls. From there, JDS expanded into portable 1-1/2- to 3hp single-stage and cyclone dust collectors about a decade ago.

Ducate has since sold his furnace company and retired. McConegly and his son Johnny operate JDS, along with a modest-sized staff. He calls the business “small and lean,” with an emphasis on quality products and customer service. For instance, John says it’s typical for him to spend an hour or more on the phone with woodworkers helping them determine their needs from a Multi-Router or consulting on the design of their shop dust collection system. That’s all in a day’s work.

And what of the 25th anniversary? McConegly says JDS “won’t be blowing too many trumpets or banging too many drums,” but he’s proud of where the company has come over the years and what it stands for now, especially in terms of the Multi-Router that started it all.

“So many of today’s power tools are disposable. As soon as the battery dies or the tool stops working, into the trash it goes … We stand behind a 25-year-old machine with amazing versatility. It’s truly something you will buy only once and pass on to the next generation. There aren’t many other tools I can think of that offer that kind of potential these days. We plan to keep it that way.”