Even though JET has been building woodworking machinery for more than a half century, its engineers still find opportunities to innovate. For instance, just last year the company rolled out two new drum sanders — its JWDS-1632, which can sand workpieces up to 32 in. wide, and the JWDS-1836, that can tackle 36-in.-wide panels or boards. You might also have seen news about three new steel-frame band saws in 15-, 18- and 20-in. capacities. In case you’re shopping for either a new drum sander or band saw this summer, Michael D’Onofrio, product manager of woodworking, would like to direct your attention to several cutting-edge features of these new models.

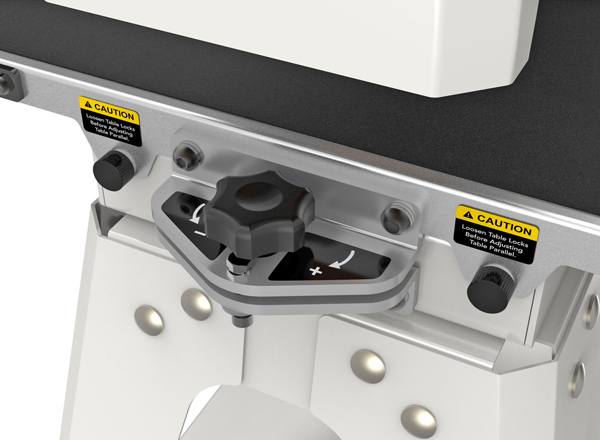

One of the big “pain points” of drum sanders, he says, is how the conveyor bed is adjusted for parallelism. On many sanders, the process involves manipulating a number of Allen screws and then using a gauge block or another tool to verify the bed and drum setting. But, on the new 1632 and 1836 machines, JET has taken the wrenches out of the process: a single dial outside the bed now controls parallelism instead.

“Our tool-less system allows the user to move the sander in and out of parallel quickly and simply, but with ultimate reliability, consistency and accuracy,” D’Onofrio says.

Parallelism of panel and board faces is an important benchmark for any drum sander, but so is the ability to sand smoothly and efficiently without leaving abrasive ridges or burn marks in the finished surface. The new JWDS sanders achieve surface smoothness with a two-part system. First, they both include Sandsmart™ technology. “Sandsmart (refers to) the intelligence of the drum sander to detect the load placed on the drum and slow down or speed up (to the speed the user set it at) the conveyor accordingly,” D’Onofrio explains. Additionally, Sandsmart prevents burning and gouging as the material is fed through the machine.

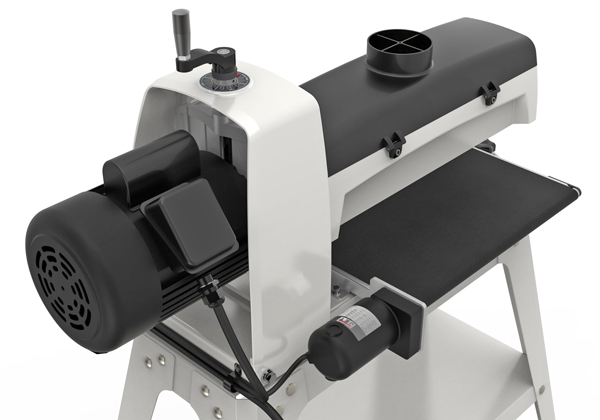

JET has also updated the feed system on the new sanders. On previous models, the conveyor motor pushed workpieces past the drum. Alternately, the new machines have a “pull through” conveyor style now, with the motor located on the outboard end of the conveyor. “It results in a more consistent feed rate, less wear and tear on the motor and a more consistent finish on the workpiece,” he says. “These two technologies ensure the workpiece has the best finish possible and the longest life possible for the sander.”

A third big improvement for both sanders is a redesigned dust hood that, JET reports, will collect 97 percent of all dust created when the machine is paired with a JET cyclone-style dust collector. Redesigned “from the ground up” and made of molded, reinforced plastic, the new patent-pending dust hoods are able to better capture dust coming off the sander than previous hood designs.

“By using industrial plastic, we (are) able to mold the hood to conform to the drum’s shape completely. This results in the ability to collect 25 percent more dust than leading competitors,” D’Onofrio says.

In order to verify dust collection efficiency, JET turned to third-party testing, pitting its 1836 sander against a competitor’s comparable drum sander. Both machines did the same amount of sanding on medium-density fiberboard and were attached to identical cyclone dust collectors. The results concluded that the competitor machine inconsistently collected 79 to 90 percent of the dust generated, while the JET JWDS-1836 collected 97 percent of the dust consistently.

Regarding the new band saws, D’Onofrio says improvements to JET’s new JWBS-15, -18 and -20 models were undertaken to deliver better performance, a better blade guide system and more resawing capacity — three improvements customers have been requesting. One performance enhancement that promises more consistent cuts is the machines’ larger, heavier cast-iron flywheels. They’re 42 percent heavier than the competition, D’Onofrio reports, with a larger center bearing and a larger cast-iron belt drive wheel.

“The larger cast-iron wheels allow more momentum to be transferred into the cut, resulting in great cut consistency. Also, the larger wheels allow (our saws) to handle larger blades in order to dissipate heat better and preserve tooth longevity.”

Two other design improvements to these saws will help woodworkers get a leg up on resawing and blade changes. First, the rip fence’s micro-adjust feature has been improved with a more refined adjustment mechanism. The fence’s updated micro-adjuster enables the fence to be shifted left or right in just 0.05-in. increments — helpful for fine resawing and cutting thin veneer. JET also has replaced a hollow guide rail (common to many band saws) for the fence with a cylindrical, solid-steel version. “The solid guide bar can handle more force applied against it than a hollow bar,” D’Onofrio says. “Our previous band saws had solid bars as well.”

Changing blades promises to be faster and easier on these three new saws, too, because the upper and lower ball-bearing blade guides now have tool-less adjusters. The upper blade guides mount to a four-sided guide post for optimum rigidity, and it moves up and down on a rack-and-pinion gear.

“The ball-bearing guides on the new JET band saws are more durable and create no sparks when compared to … ceramic blade guides,” he adds.

Improvements to the designs of these two new drum sanders and three band saws point to “JET’s relentless passion to be the market leader in woodworking,” D’Onofrio assures. “Customers should be confident in the power, durability and accuracy of JET tools. We stand behind our work making these machines, so you can stand behind your work.”

Learn more about JET woodworking machinery by clicking here.