With the exception of blade brake technology in table saws, most other developments in stationary woodworking machines are incremental improvements of long-standing features — better fences, larger tables, improved cutterheads and so forth. But rarely, if ever, does the very heart of the machine — its motor — end up back on the drawing board for improvements. Today’s universal or induction AC motors in woodworking machines seem stalled in early 20th-century technology, and on some machines, the limitations can be frustrating.

Take lathes, for instance. If a gouge catches while turning a bowl, the motor doesn’t know the difference and the piece keeps spinning, regardless of the damage to the wood or in spite of the fact that the tool is now jerked free of your grip. A typical lathe motor also can’t compensate accordingly for increased loads; if you make an aggressive cut that exceeds motor torque, it will bog down. And, of course, there’s the annoying need to change between drive belts if your lathe isn’t equipped with variable speed. Belts also increase vibration and decrease the efficiency of power transfer between the motor and the headstock spindle. It’s an inefficient pairing.

Teknatool took lathe motor technology to task back in 2003 and revolutionized it when it released the DVR 3000 lathe. Unlike any other lathe on the market at that time, the 3000 was powered by the company’s DVR switch reluctance motor. It has no brushes, rare earth magnets or windings around the rotor. That alone is major change. But of equal importance, it’s controlled by a computer that keeps tabs on motor performance every second the lathe is in operation.

“It is a true variable speed motor as it simply doesn’t care what speed it is set to,” says Joel Latimer, vice president of Teknatool International and president of DVR Technology Developments — an offshoot of Teknatool. “And the rotor is closely monitored in terms of position, so as more load is applied, more power is drawn to ensure the spindle maintains the set speed no matter what the load.”

For woodturners, those two aspects — speed control and constant power output over the speed range — are huge improvements. DVR lathes are also direct-drive and have no belts to switch, so underpowered bog-downs are a thing of the past.

Latimer points out numerous other advantages to DVR motor technology. For one, the only wear items in the motor are its bearings. There are no brushes and windings to replace due to friction, heat buildup and power surges at startup. They also draw low amperage when initially turned on, which prevents circuit breakers from overloading and popping off.

Smoothness of power delivery is another big plus, Latimer says. “Our famous coin test where we placed a quarter on the headstock and ramped up through the speeds has not been replicated.”

But probably key among the DVR improvements over conventional electric motors is the presence of a central processing unit that makes the motor functionally smart.

“Our lathes have intelligence that when you have a chisel catch, the lathe will stop instead of ripping the chisel away from your hand… We need that kind of intelligence in the workshop.”

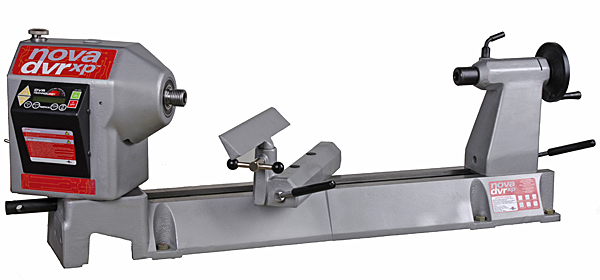

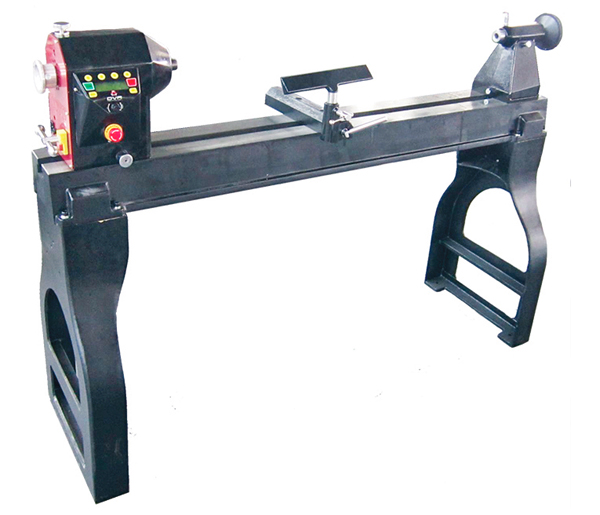

These days, Teknatool offers three lathe models with DVR motors: the 16-in. DVR XP, a 20-in. DVR 2024 and a new-to-market 16-in. DVR Galaxi. And, coming in January, Teknatool will apply the benefits of DVR to another staple woodworking function: drilling holes. As the company’s answer to “smarter” drilling, its new NOVA Voyager 18-in. Drill Press will have 6-in. of quill travel and sports a 16-1/2-in. square woodworking/metalworking table. The machine will be floor standing at 65-in. tall with a compact footprint.

Latimer hopes the new drill press will appeal to seasoned woodworkers who would appreciate, among other things, not having to move grimy rubber drive belts between pulley sheaves in order to change drilling speeds. Voyager will be direct drive. He also thinks the technology will be attractive to today’s smartphone-wielding youth who are curious about woodworking but haven’t benefitted from traditional school woodshop educations.

For instance, the new drill press will have a speed chart among its touchscreen display options. That function will allow users to select from a wide range of drill bit styles, sizes and even types of workpiece material. The computer will tabulate this input and offer a recommended optimal drilling speed.

There’s also a depth set function, with the machine beeping a warning as the desired drilling depth approaches. “The motor automatically stops when the drill bit reaches the set depth,” Latimer adds. “Combined with the convenience of zeroing (the bit) at the press of a button, this makes drilling to an accurate depth quick and easy.”

A pilot hole and tapping feature will enable the motor to respond to input from the workpiece and bit, in a load-sensing mode, so it knows when the cutter is properly seated in hole and when it should switch direction for chip breaking as well as backing out of the hole at the end of the cycle.

Aside from ease-of-use convenience, Latimer says the Voyager will be resplendent with safety features too. For one, the motor will stop instantly when the drill bit catches instead of pulling the workpiece out of your hands or away from a vise. It does this by monitoring load levels and applying an electronic brake, which can be pre-programmed. The drill press can also be set to sense tilt and excessive vibration. There’s a password lockout, too, preventing unauthorized use.

Clearly, this will be a “next generation” machine, and Latimer hints that lathes and drill presses are just the tip of the iceberg in terms of how DVR could improve woodworking. When asked what other machines could be options for DVR motors, he believes “anything that needs a motor to perform, in all honesty.”

The company is even considering DVR for handheld power tools.

With the promise of versatility, reliability, constant torque across its powerband and better safety features, the new Voyager 18-in. Drill Press won’t be the least expensive floor-standing drill press on the market. Latimer says it will retail for $1,499 and will be offered through vendors such as Rockler. But it surely will be a game-changer, and that’s what Teknatool intends to do with all of its DVR offerings.

“At the heart of every tool is the motor. Unless you are designing and changing the potential of the heart, you are really (just) playing with colors and bells and whistles. This is what makes our work so exciting.”

Learn more about Teknatool woodworking products by clicking here.