Here’s a quiz: name five of today’s major woodworking machinery manufacturers.

Is Oliver Machinery on your list? If it isn’t, maybe that testifies to how broad the machine tool industry has become. Or possibly, the first brands that come to mind are those you own or whose ads come to mind from your favorite woodworking publications, blogs and websites. But the next time you’re in the market for a new machine, consider Oliver; it’s an iconic brand that’s been a staple in the wood shops of schools, military bases and industry for more than 100 years.

Last month, while attending the International Woodworking Fair (IWF) in Atlanta, I stopped by Oliver Machinery’s booth to check out one of their new 1013 intelliCarve CNC machines. Here’s a video from that visit which highlights the tool.

Oliver’s presence at IWF impressed me for a couple of reasons. First off, they were there. What I mean by that is, a number of popular machinery manufacturers no longer include national trade shows like IWF in their marketing agendas for the year, and those absences are conspicuous. But, while there are various reasons why some big brands have pulled out, Oliver was there, and in force. The booth was substantially sized and crowded with the company’s current machinery line. It includes both the standby offerings you’d expect — table saws, band saws, jointers and planers, shapers, drum sanders, dust collection and more — plus a few things you wouldn’t necessarily anticipate, like a membrane press for laminating sheet goods as well as CNC machines. I was impressed by the variety of offerings because, honestly, it’s a product line I didn’t know very well.

So recently, Lisa Clark, Oliver’s marketing manager, was happy to bring me up to speed. “Our company was founded by Joseph Oliver around 1890. He was a machinist by trade who developed his own version of a wood (miter) trimmer machine after selling another company’s wood trimmer for a number of years. Oliver thought he could make a better tool, and he did.”

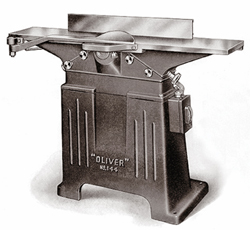

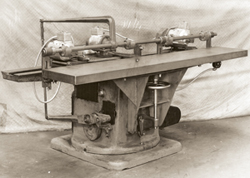

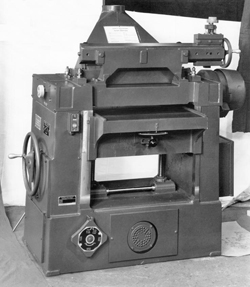

Oliver’s wood trimmer won him a gold medal for merit at the 1900 World’s Fair in Paris. But it was just the first of many innovative woodworking products that would come from the Oliver Machinery Company. In 1908, Oliver introduced a cylindrical cutterhead that would eventually replace the square — and more dangerous — cutterheads used commonly in certain machines of the time. There was also his Straitoplane, introduced in 1923 as a combination jointer/planer, which could surface a warped board straight and flat in one pass. It’s a design other companies would emulate in the years to come. From its factory in Grand Rapids, Michigan, Oliver also produced a variety of woodworking machines as wells as other tools as the market presented new opportunities. The plant churned out bread slicers during the Depression, metal-cutting saws during World War II and even packaging and printing machinery during the 1950s and 60s.

“By the late 1970s into the mid 80s, more woodworking machinery companies were closing their American manufacturing plants and sending production overseas. Oliver fell into harder times as the costs of production rose. There were labor issues and even a few lawsuits,” Clark recalls. New woodworking machines sourced from Asia were less expensive for woodworkers to buy. For a variety of reasons, the company filed for bankruptcy in 1986.

Still, even through some turbulent years Oliver’s production continued, and by 1994 the company had manufactured some 150,000 machines here in the United States. It was estimated at the time that about 75,000 of them were still in operation on a daily basis. The company had forged a reputation for reliability and ruggedness, particularly in terms of its heavy cast-iron tool bases.

In 1999, a group of investors purchased Oliver. In order to remain competitive, the Grand Rapids plant was shuttered and manufacturing was directed offshore. The company’s U.S. headquarters were moved to Kent, Washington. But curiously, one important link to Oliver’s Michigan heritage remained.

“Our last Grand Rapids plant manager, Rich Fink, bought Oliver’s remaining parts inventory plus the sales records and the old blueprints. He uses this information today to help owners of Oliver machinery made prior to 1999 restore and service their machines through his business, Eagle Machinery and Repair Company. When Rich can’t find an old part, he can fabricate it or have it cast to the original specifications. Rich is also one of our current Oliver dealers as well as our historian and an important tie to our company history.”

Lisa says that one of the challenges of the “new” Oliver Machinery is helping customers understand that overseas sourcing doesn’t have to mean diminished quality. “We are extremely particular about who builds our machinery in Taiwan, and in the Oliver tradition, our machines are built to last … our new machines are built in the shadow of our older tools, but with better safety features and the latest technology. Our overseas partners build to the specifications we require, and our quality standards are very high.”

Up until just a few years ago, Clark says Oliver was primarily a “mid-line” tool supplier to schools, military and industry, but now the company has broadened its catalog to include 10-in. table saws, plus smaller jointers and planers among other options for the serious hobbyist. “We’re definitely going to continue to grow the smaller side of our product line, based on what woodworkers want us to make. We’re very picky about what we bring into the line, but if we get enough requests for a new tool, we’ll definitely consider it.”

Lisa encourages woodworkers who are in the market for a new machine to make a simple weight comparison between an Oliver tool and a competitor’s tool. “I tell customers all the time, the heavier a machine is, the more you’re getting in terms of ruggedness and vibration dampening from thicker, more substantial castings. That’s where our quality shines through and what really sets us apart. It always has.”

Some Oliver loyalists might wish for the days when when everything with an Oliver nameplate came from Michigan. But the trends of manufacturing and our buying patterns have indelibly changed this industry. Still, Oliver’s legacy continues on in an evolving marketplace. If IWF was any barometer, it seems Oliver plans to be part of our woodworking culture for many more years to come.