The year was 1993, and Jim Rees didn’t have a woodworking shop, much less a woodworking business. Yet there he was, building bunk beds in an 8 x 10 plastic tent outside his apartment in the dead of winter. During other seasons, too, but right through winter’s worst in the coastal city of Gloucester, Massachusetts.

“It must have been pretty funny to see a guy in a plastic tent with the ground frozen solid, just 100 yards or so from the Atlantic Ocean making bunk beds. Ridiculous! But hey, I was making money!” Rees quips.

This bunk bed venture had all started out innocently enough. Rees made his first bunk beds for his kids, and those beds led to more for his nieces and nephews. Once each of them had a bunk bed, he thought that would pretty much be the end of it.

“I never intended this to be a business. I’m not a woodworker, and in fact, at that time I hadn’t even really used woodworking equipment. I was running a construction company, so I knew framing, not woodworking. But before I knew it, I was getting calls on the job site from the parents of friends of my nieces and nephews wanting bunk beds themselves. They were willing to place orders,” he recalls.

While he found the calls surprising, they weren’t unwelcome inquiries. Jim says he had previously been looking for about 10 years for a means of making more money in the “off” season of construction. When the calls kept coming in for bunk beds, he started to believe maybe this was a possible solution. So, he kept building beds. After about eight months, the opportunity seemed clear; he passed the construction business on to one of his foremen so he could focus on bunk bed production full-time.

After about a year and a half, Jim had more work than he could keep up with, so he broke the New England area up into 50-mile radiuses and hired other woodworkers to build bunk beds for him to keep up with the demand. He gave them a cut of the profits. The proceeds also allowed him to build a 2000-sq.-ft. shop with “all the best woodworking equipment,” but he knew the long-term potential of his local market was limited.

“I didn’t know quite where to go from there, but I credit my extended family and our rather unusual family style in helping me figure it out.”

Jim explains that business interests run deep in the Rees family. “Instead of board games, my father would sit down with us kids, and together we’d analyze businesses for hours and hours. Around the dinner table, we’d often talk about business instead of how our days had gone that day like other families. It’s just something we all did … we thought it was normal.

The youngest of five, Jim grew up around retail, construction and publishing businesses, run by his other four siblings and their spouses. It provided a wealth of knowledge about any number of things, but probably most valuable to Jim was how to market products successfully. So, in order to plot the course for his bunk bed business’s next step of growth, Jim took a full year off from work and formulated a business plan. During his “sabbatical,” he wrote a manual — one volume on marketing strategies for running a bunk bed business and the other documenting the plans and jigs required to build several different bunk bed designs. He also contacted a telecommunications company to learn more about the possibility of routing toll-free phone numbers, and he acquired the telephone number 1-800-Bunkbed as well as the website 1800bunkbed.com.

“Once I entered that phone number into all of my advertising, my sales tripled within six months.”

With these various elements now in place, things were ripe for significant expansion. In 2002, Jim took the business from regional to national and opened his company 1-800-BunkBed to a much wider audience of potential woodworking business owners. “I was working from home, I set my own hours and there were never any slow times. It seemed like the perfect opportunity for other woodworkers to do the same thing starting their own independent bunk bed businesses using the phone number 1-800-Bunkbed and my training manuals.”

That was more than 17 years ago. Now, there are woodworkers in all 50 states and most provinces of Canada building Jim’s bunk beds.

Here’s how Rees’s opportunity works. For a monthly fee that starts at around $285, a woodworker can gain access to his or her local territory of at least 100,000 people, provided another bunk bed business owner does not already have rights to the same territory. Territories are based on county designations, and the monthly fee gives the 1-800-BunkBed owner protected access to that potential clientele. The actual monthly fee of a specific territory can vary, based on population. The telephone number 1-800-Bunkbed routs customers within a territory directly to the business owner. The company also provides a personalized website and business email address. From there, it’s up to each bunk bed woodworker to determine the manner in which they want to market their business, how much business they want to take on and, implicitly, how much time they want to devote to this work.

The work can be done part-time to supplement other income, or full-time. Jim says the income-earning potential for about 20 hours per week of work is around $50,000.

“These aren’t franchise businesses,” Jim insists, “because franchises have huge upfront costs; there are none of those upfront costs here, aside from a one-time setup fee of $95. We also don’t want to take a percentage of a business owner’s sales. It’s basically a licensing agreement we’re making with our business owners for building a nationally recognized family of bunk bed products. It’s set up for entrepreneurs. There’s also no long-term commitment beyond a six-month initial period. After that, it’s month by month for as long as you want to continue to run your bunk bed business and pay the monthly territory fee. The fee for your territory will remain the same.”

You don’t need an extensive shop to build these bunk beds or a big inventory of tools. Jim says a circular saw, drill and sander are sufficient, “and that’s all I used for probably the first 100 beds I built.” Shops of most any size can handle this work, but around 200 sq. ft. of floor space or more is ideal. A garage, basement or even a spare room of an existing business all could work.

Each 1-800-BunkBed business owner can set the pricing of his or her beds, but typically beds retail for between $300 to $550 for the best-selling model. They’re usually built of 2×6 dimensional lumber, but any species of lumber could be substituted. An experienced woodworker can build a bunk bed in under four hours from start to finish.

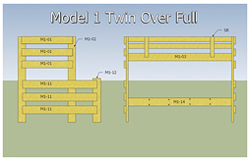

Jim credits several factors for the success of his company and its independent business owners. For one, bunk beds are a “universal want” of kids and a practical solution for college students. “We’re also providing an American-made product custom-made by local craftspeople, so we’re supporting local business and getting people back to work. Our seven different bunk bed models are rock-solid and have proven designs that meet all applicable safety codes. They cost the customer about the same as 90 percent of mass-produced bunk beds that are manufactured in the Pacific Rim these days.”

Marketing, Jim reports, is the most challenging aspect for most woodworkers who want to sell what they make. “Woodworkers just aren’t used to doing it, but the right kind of marketing is essential to run any business. Our business manual and call-in service network can help our business owners to be successful in this area. When you call, you talk to a live person and just ask your questions.”

Rees assures that, although there are bunk bed businesses operating in every state, “there’s plenty of opportunity to come on board now.” If a territory is already taken, woodworkers are put on a waiting list and contacted when their territory opens up again. Click here for a more extensive explanation of how the process works and to read answers to frequently asked questions.

“What excites me most about this business, is that we are giving woodworkers the opportunity to live a life they never thought they could live, running their own independent woodworking businesses from home. We give you all the tools you need to succeed. Full-time, part-time. You decide.”