Fifty-six years ago, woodworkers needed a more convenient solution for purchasing supplies and hardware. So Nordy Rockler, his brother Bill, a mutual friend and one other partner started a catalog business to create a better supply chain. They were among the first people to do that for hobbyist woodworkers. A half century later and counting, we woodworkers are still benefitting from that idea. The 196-page Rockler Master Catalog and an extensive product website testifies to it.

Over the years, Rockler Woodworking and Hardware has continued to build on that first innovative venture. Sure, the catalog business, direct mail and some 30 national Rockler stores keep our shops filled with the essentials from across the industry — hardware, tools, lumber, finishing supplies and so forth. But Rockler also brings to market its own line of proprietary products aimed at making our hobby even more productive, easy and enjoyable.

Want to know who comes up with those clever new Rockler gizmos? A team of four product development specialists, some key outside vendors, and — drum roll, please — end users! Many of Rockler’s new innovations are the result of good ideas supplied by fellow woodworkers and garage inventors. In other words, Rockler customers.

Recently, I talked with with Steve Krohmer, Rockler’s vice president of new product development, to learn more about how this collaborative process works. Steve explained that years ago, most new product concepts came from the in-house development team. They’re a mix of industrial designers and marketing folks but, of equal importance to Steve, they’re also active woodworkers and creative problem solvers. Product development has also benefited from the input of other woodworking employees within the company. They meet in a cross-departmental team to review prototypes or new products and offer advice.

While collaborative thinking has been a long-standing tradition, the company also prides itself in providing a supportive environment for sharing those new ideas.

“We’ve always had three main tenets for new product design. First, while ideas for new products might get criticized, we don’t criticize our team members. Second, we accept failures along the way and learn from them. Third — and this is really the cornerstone of our new product design — we embrace the K.I.S.S. principle of Keeping It Simple, Stupid.”

That focus on simplicity is what drives the product development team to ask the important question: can a new product solve a basic woodworking problem — a “pain point,” as Steve calls it? And, can Rockler invent it with better features and benefits than other options on the market? If the idea fizzles on either account, or if it seems cost-prohibitive to end users in the long run, it isn’t pursued further.

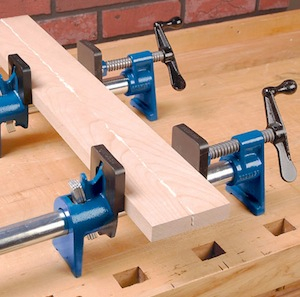

At times, however, the failure of one idea becomes the genesis for something new and more viable. Krohmer says the Sure-Foot Plus™ Pipe Clamp, for example, is the byproduct of a completely different idea that didn’t get developed. Steve commented that “sometimes we have to stop what we’re doing to prevent a losing proposition or go back and question our original assumptions to come up with a better product.”

The simple, cost-effective approach has been key to two of Rockler’s biggest successes over the years. Krohmer says Rockler’s JIG IT® Drilling Jigfor shelf-pin holes has been part of the product line for 17 years, and it’s now in its third generation of development. Rockler also stepped into the router table market back in 1995 when the available options were few and expensive. The blue aluminum router insert plate, a fully functional fence and options for tables and bases all enabled Rockler to provide quality solutions more affordably than the competition.

In the past seven to 10 years, however, Krohmer says there’s been a bit of sea change in Rockler product innovation. Now, collaboration also happens quite often beyond the corporate front door. It is customer-driven. At times, the litmus test for new products takes place right where woodworkers shop. Steve points out that “every two to three months, we host what we call External Voice of the Customer (EVOC) meetings at our Twin Cities area stores. Here, we go through brand-new proprietary products with our customers to get their feedback.”

That EVOC response has literally changed the design of some products and confirmed the plausibility of others. Steve cited two recent cases: “Our new Interlocking Signmaker’s Templates are the direct result of feedback from customers wanting us to get down to the basics. We originally were planning the templates to fit into a more complicated framework; now they just lock together like puzzle pieces. They’re simple and effective. Another good example happened when we were engineering our heavy-duty mobile base with oversized casters. We thought that its price point might be too high to make it a valid product, but our customers felt otherwise. They saw the value of spending extra to get the benefits of a better mobile base.”

Sometimes products that end up in the Rockler catalog began as inspirations in home shops. The Clamp-It™ Assembly Squares, Pock-It Hole Clamp™ and a new ice cream scoop turning project all were originally customer ideas. Rockler partnered with the inventors and offered compensation for the results. “We really like to receive inventions and ideas for new products from our customers and to co-develop products with them…We want to support the creative spirit in the woodworking community this way,” Steve says.

He believes that at the end of the day, Rockler’s product innovation is like the proverbial ball game. “We swing for singles and doubles — just simple hits that create a continuous flow of new products that we can sustain over time. And as long as we keep the string of hits coming, those home runs and grand slams are going to come our way too.”