Remember those clever all-in-one tools like the Shopsmith? The idea was to have one machine that took up limited space but could do almost every woodworking task. Well, say hello to ShopBot, the modern answer to that age-old problem.

The entry-level ShopBot is a tabletop tool that theoretically could replace every tool in your shop. It cuts, carves and shapes, can do just about every wood cutting task from the mundane to the frighteningly accurate and specialized, and will never cut a finger off.

“Is he talking about a CNC machine?” I can hear you saying with incredulity. “He must be nuts. Those things are big, expensive and difficult to use.” Many are, it is true, but this one is a welcome exception, designed by a hobby woodworker to solve his own challenges on the cheap. A basic model starts at around four thousand dollars, not much more than a good table saw or plasma TV screen, and though it costs a lot more than a hammer or chisels, it is considerably less than the combined value of the shop full of common woodworking tools it replaces.

“When you think of it as something that allows you to express your imagination and designing talent, it may be downright cheap,” insists Ted Hall, the president and founder of the company. “The range of what you can make, design or create on a ShopBot is endless. Think of it as a personal robot that empowers your creativity, or a shop buddy with really good hand-eye coordination.”

CNC, which stands for computer numerically controlled, simply means that a computer tells the cutter exactly where to go and what to cut. The level of precision is beyond what most of us can routinely accomplish or even need, and once it has its program in place, it works quickly, efficiently and tirelessly. While CNC machines are not new to the field, something affordable is a serious departure from the norm. For that, we can thank an academic who wanted to make a boat.

Ted Hall was a neurobiologist by training, and a professor and research scientist at Duke University. He started ShopBot as a second job about twelve years ago. “I was interested in building plywood boats in my back yard,” Hall explained, “and set out to create CNC software for designing them. The problem with plywood boats is that they all look like shoeboxes, but with modern software you can design something more interesting and complex. If you have the right pattern to cut the flat parts out, when you put it together it will take the form you want it to take. Computer modeling makes that easier, so 15 years ago I developed a program for backyard boat builders to do it on their own.

“I found myself printing out and taping together all these templates for cutting boat parts and figured it would be a lot easier to just hook up a router instead of cutting them out with a jigsaw. By then, I knew what a CNC router looked like. To me, it was just a giant plotter with a router instead of a pen, and I could not see why it couldn’t be built for a thousand bucks or so instead of the 50 thousand needed to buy one.

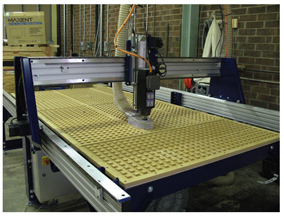

“I built my first router-based CNC machine out of plywood. It consisted of a table with a gantry, or moving beam, along which a router can ride. That allows you to cut in two dimensions. By adding another, smaller beam you can also let the router move up and down, adding the third dimension. In addition to a plywood frame, I used an assortment of common hardware like patio door wheels, cables, nuts and bolts and stepper motors. A stepper motor is a unique, brushless motor that makes digital positioning moves, which interfaces nicely to computers. The computer can tell it to make a step of any size, and it can do that. That first one cost just a few hundred dollars in motors and electronics, but took several months of my spare time.

“One interesting characteristic of it was that it was self-replicating. In other words, it could cut all the parts to make another one. It seemed almost Star Trek – a replicator that you tell what you want and it spits it out.

“I took the tool to show and tell at a woodworking club and met two guys who later became principals in the company, both former woodworkers with a lot of experience in professional woodworking. We grew from there. Over the past 12 years, we have grown into the largest producer of affordable CNC routers, with about 30 employees building some 6000 units per year in Durham, North Carolina.

“Initially, I planned on simply creating a set of instructions and a hardware kit. I figured the wood parts could be made on a friend’s or neighbor’s ShopBot. The problem was that it would not scale up, because when you made the plywood gantry bigger, it sagged. I went to Home Depot and found utility strut – long, chrome-plated steel U-shaped channel with slots cut into it used to hang lights and other parts. It became both the rails and gantry of the next iteration.

“We soon discovered that we could buy the hardware at a quarter the price by buying in bulk. For instance, that first kit had 36 patio door rollers. Most stores don’t stock that many, and they are more expensive to boot. Another way we manage to stay affordable, even today, is that everything is modular. The smallest and largest tools we make use the same modules.

“I thought my customers would be hobby woodworkers and assumed that for a couple thousand bucks everyone would want one. Instead, my first customers were small cabinet shops and sign makers. They knew what a CNC tool was, had wanted one for a decade, but couldn’t afford one. They expected to make a buck with it the day after they got it. They all said they would pay a bit more if it were a little faster, a bit more powerful, and already put together, so we did that. We morphed the kit into something that merely needed to be assembled. In fact, we went through four stages of changes, from ‘make most of it yourself’ to working models that have only four parts to assemble.

“We have gone from a tool that looked like an erector set to one that looks like a serious machine. We have also gone to performance levels on our 12-thousand dollar tool that are equivalent to an 80-thousand dollar tool from our competitors.

“We still want to grow the low end of the CNC market. There’s a big part of me that is interested in getting CNC into the shops and garages of DIY woodworkers. We call our tools PRS or personal robotic systems because we want to orient the tools to be used by people, not large companies. We made something that might not have the speed and power of a huge commercial tool, but is accurate and easy enough to be usable by an ordinary person. That does not mean larger companies don’t appreciate them. Companies like Boeing buy them as well. The largest custom cabinet company in the U.S., a company with 2,000 employees, has 12 ShopBots. Nevertheless, I feel robotic tools are wonderful for individuals in their small shops at home, so we continue to work on getting the cost and size down so that they fit into both the shop space and budget of the hobby woodworker.

“My orientation is from education, so I am big on the education process as well. Hence, we have lots of training and education resources on our web site. Customer support follows the same lines. We provide free software upgrades for life, and the software is continually being updated. The software we use is very easy to run, but it is also flexible enough and full featured enough that you can modify it or extend it to do what you like. We also provide 24/7 technical support locally, not somewhere in India. There is always someone on call, right here at ShopBot in North Carolina, day and night. We understand that many of our customers are depending on our tools to make a living with, and we take that responsibility very seriously.

“Another unique aspect of customer support is our online forum. Our forum is uncensored, so you can read the complaints, the rebuttals and all the opinions and information our customers share. We also have an annual get-together called Shop Bot Jamboree held in various parts of the country to help users meet one another and share information, and there’s a new Wiki, or online encyclopedia of ShopBot information. In short, we go out of our way to make sure our customers are happy and productive, and that attitude permeates everything we do.”

As a result, they have managed to develop somewhat of a cult following whose members view using a ShopBot as being part of an affinity group and not just being an owner. Owner and devotee Ken Picou described the company to me as “the Tupperware of CNC” because of they way they sell and the “share the good news with your friends” feelings ShopBot engenders. When you think about it, that’s probably one of the nicest things you can possibly say about a company that makes high-tech products.